Case Examples Handbook

We interviewed the customers who had in fact installed YAMAHA robots. You can find tips that may provide solutions to your problem.

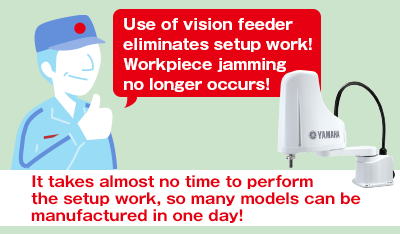

- Use of vision feeder eliminates setup work! Workpiece jamming no longer occurs!

-

Workpiece supply setup work needs to be made easy.

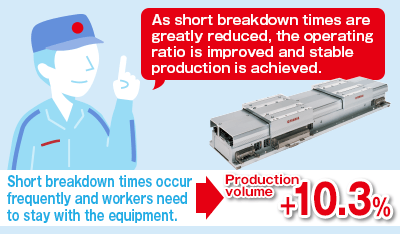

- The number of drive devices and sensors that caused short breakdown times is minimized.

-

Short breakdown times occur frequently and workers need to stay with the equipment.

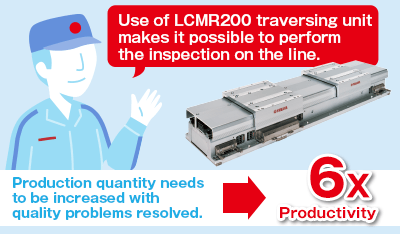

- Use of LCMR200 traversing unit makes it possible to perform the inspection on the line.

-

Production quantity needs to be increased with quality problems resolved.

- YK-TW can be stored inside the equipment and downsizing is achieved.

-

Equipment needs to be made compact even with large pallets.

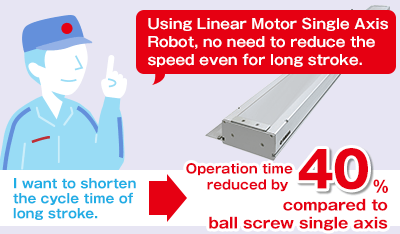

- Cycle time reduction even with long stroke

-

Long stroke transfer needs to be performed with single-axis robot.

- We want to stably produce high-quality products while saving labor.

-

Labor saving and traceability are achieved by a SCARA robot.

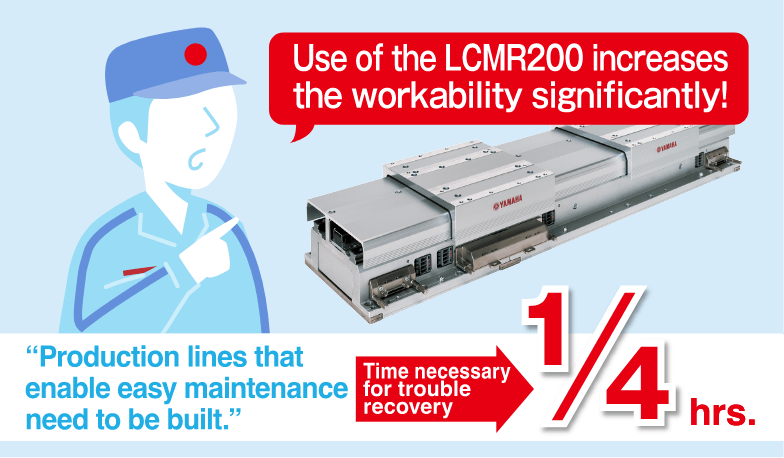

- Since the time to solve the problem issues is reduced, that provides more time for production.

-

Production lines that enable easy maintenance need to be built.

- 4 workers that were needed for the label adhesion process are reduced to 0 workers!

-

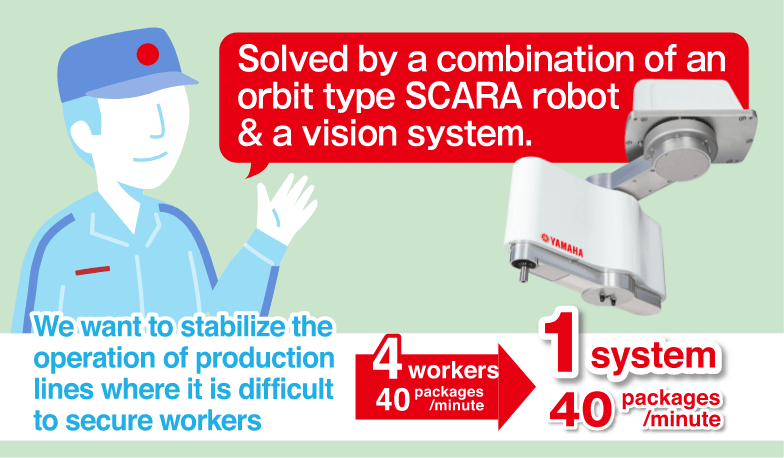

We want to stabilize the operation of production lines where it is difficult to secure workers

- Process that has required 8 workers conventionally is now operated by 1 worker!

-

The number of workers who pack baked sweets into boxes needs to be reduced

- Setup time is almost zero!

-

Manufacturing products of multiple models in small lots without lowering the operating ratio

- The production volume is increased by approx. 23%.

-

Increasing productivity per line for cost reduction.

- Shorten takt time by 2 seconds!

-

Selection of linear conveyors that defy conventional wisdom for lines.

- Challenge to width as narrow as "500 mm"

-

What makes it possible to lay out plural processes in a narrow width?

- Reduce setup time by 80%.

-

Why does it take surprisingly short time to build up a robot vision system?

- Shorten equipment startup time to half!

-

A brand new idea that replaces index tables

- We need both! – coating accuracy and speed increase.

-

What does a sealing process go for to improve productivity?

Related contents

- Member Site

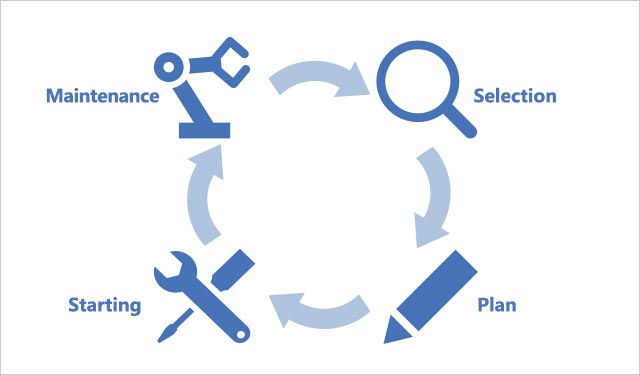

- YAMAHA Robot Member Site provides information you can utilize in the model selection or design phase when introducing industrial robots.

Additionally, the contents necessary for the start-up or maintenance work are also prepared.

- Robot Movie Channel

- Yamaha Motor Robot Official Channel

- Exhibition information

- Here you will find information about exhibitions where YAMAHA will show its latest robot products.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378