YHX Controller

Reduces production line configuration time

Controller for the linear conveyor module LCMR200 and single-axis robot GX series. Advanced production line can be constructed in a short period.

- Comparative robot:

Single-axis robots GX series・Linear Conveyor Module LCMR200 Feature - CE marking compatible:

○ - Field network:

CC-Link、EtheNet/IP、PROFINET、EtherCAT - Operation method:

Standard profile

PC Programming Software

PC operating environment

*OS : Windows 7 SP1/8/8.1/10/11 (64-bit version only for all)

*Memory : 8 GB or larger

Feature

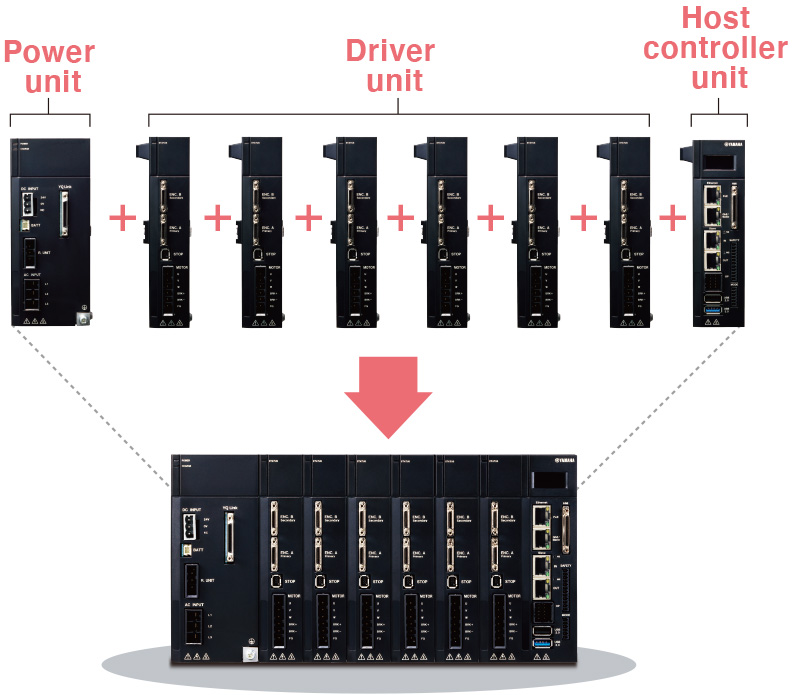

Stacking modular structure

No wiring between modules needed.

Incorporation a control power supply, motor drive power supply, high speed network communication, safety circuit into a

stacking modular structure.

Eliminates wiring between units, reducing conventional wiring cost and wiring man-hour to 30% to 50%.

The stacking structure including host, power and driver is the very first in the industry.

Typical photo image of stacking structure

Various data

YHX Controller

Related contents

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378