Robot Vision System RCXiVY2+ Usability

Yamaha's own unique solution for integrated robot vision

Usability

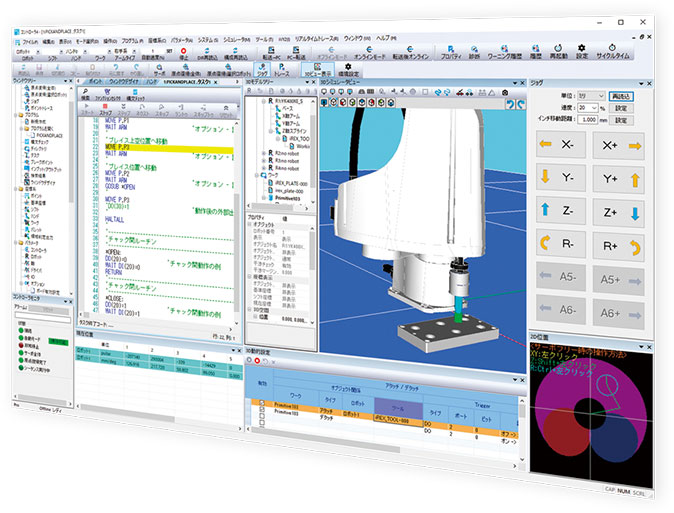

01Easy-to-use programming software RCXiVY2+ Studio

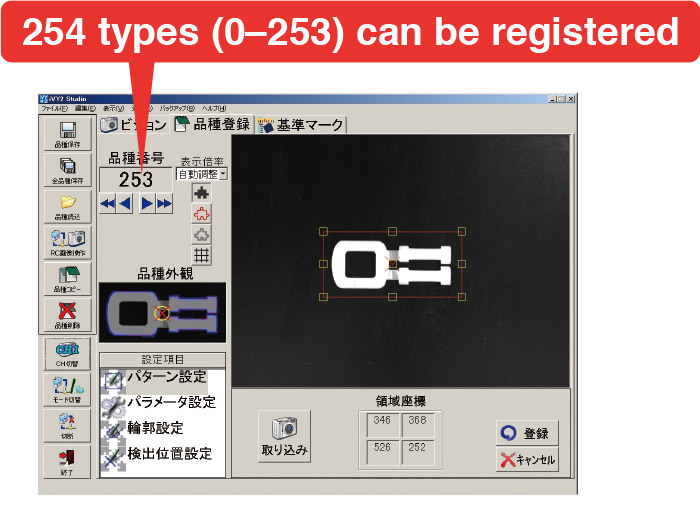

With programming software “RCXiVY2+ Studio”, all vision related operations such as registration of fiducial marks and workpieces used for calibration (contour settings, various parameter settings, and read range settings), backup, restore operation, and operation monitor can be performed.

● Search trial-run, part type registration

● Reference mark registration (for calibration)

● Up to 254 workpiece types can be registered.

● Workpiece can also be added easily.

● Up to 100 workpieces can be detected at once.

● Data backup

● This software functions as a monitor during program operation.

02Easy programming

Constructing the most suitable robot vision system for an application.

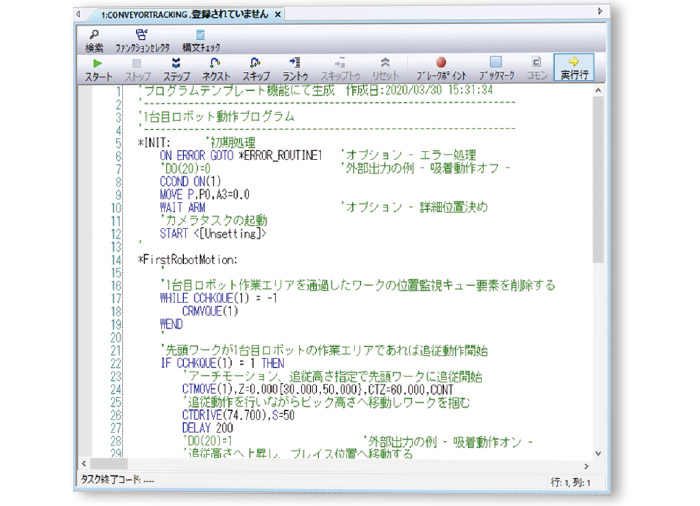

RCX-Studio 2020 program template function

Program is created automatically simply following step-by-step operating process

RCX3 series programming software RCX-Studio 2020 also has following five templates for vision system:

● Pallet picking using the vision

● Dispensing work using the vision

● Gripping deviation correction using the vision

● Gripping deviation and mounting position correction using the vision

● Gripping deviation and mounting position correction using the vision (without using any master)

03Wide variety of robot system to choose from most suitable and economical solution for robot vision system

XY-X Cartesian robots

YK-XG/XE SCARA robots

Clean SCARA robots

YK-TW orbit type robots

FLIP-X single-axis robots

04Up to 254 types of parts registration

Setup changes require only that part numbers be changed. Setup changes are easy.

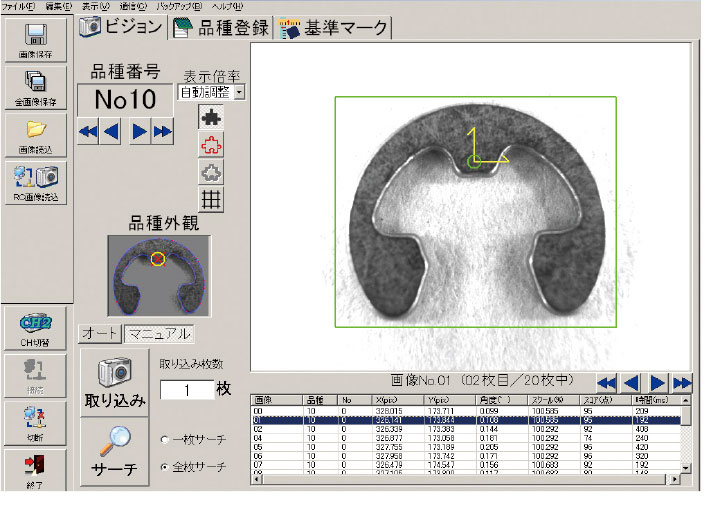

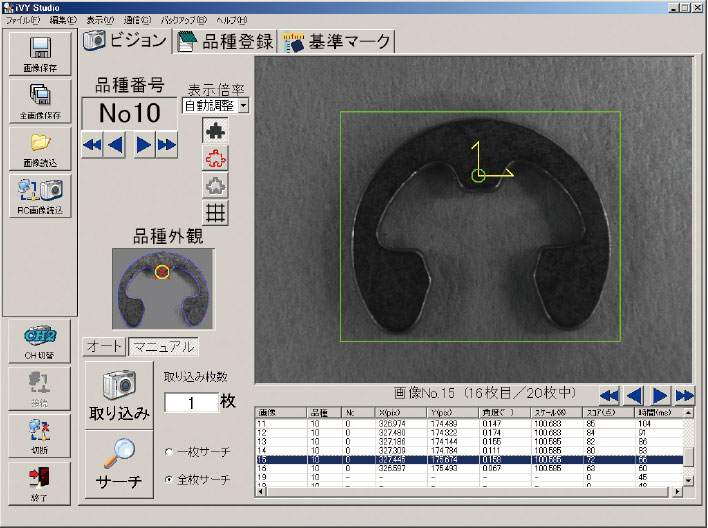

05High-precision search even under low light

Edge search engine is built-in

Supports a variety of applications while being minimally affected by the external environment.

When lighting is sufficient

Accurate search even if lighting is insufficient

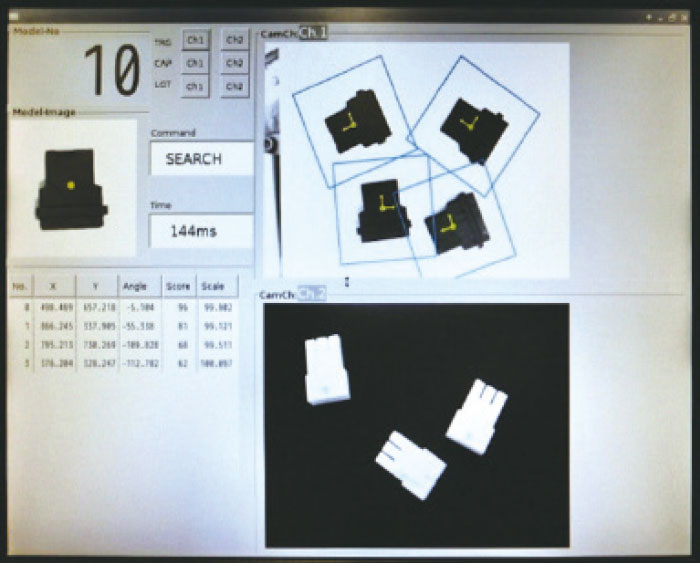

06Monitor output

Monitor the operating status

Monitor the search status while making calibration settings or during automatic operation.

Contents of output

· Selected type / Captured image

· Search result (position, score, scale)

· Executed command

· Time required by command

Output method

・DVI-I (supports digital monitor or analog monitor)

07Lens distortion and camera inclination correction function

Mounting accuracy is improved. Camera is installed in the inclined status. ** Up to approx. 15 degrees

The lens distortion and camera inclination when the angle of visibil-ity is wide or when the camera is installed in the inclined status can be corrected.

When the distortion and inclination correction function is enabled during calibration, the calibration data for the distortion and inclina-tion correction is created. When images are captured using this calibration data, captured images are corrected and output.

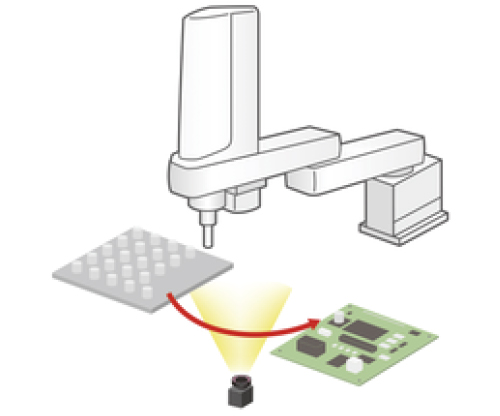

08Also supports moving camera

Even if the camera is mounted on the robot, coordinates are automatically converted according to the robot's movement.

Camera position can be selected in accordance with the application.

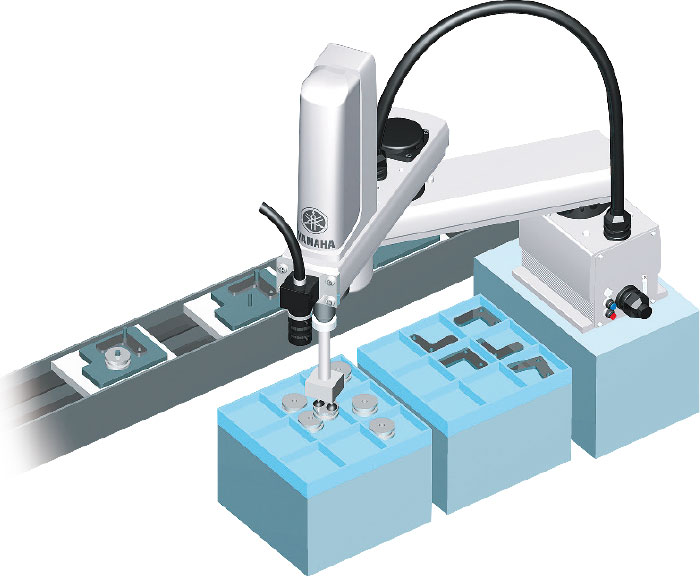

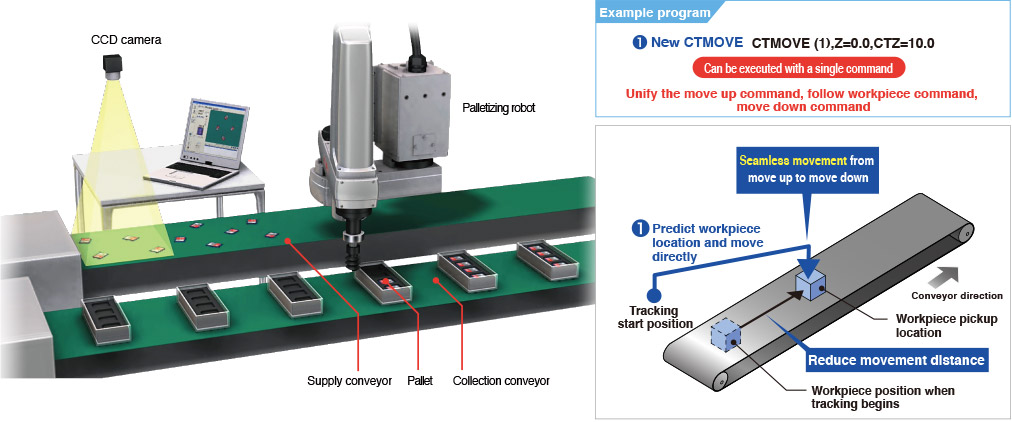

09Conveyor tracking

Ideal for high-speed packaging arrangement high-speed transport of multiple types of items such as pharmaceuticals, cosmetics, and food products.

The vision camera detects the position and orientation of parts moving on the conveyor, and the robot picks them up.

Operating conditions: YK500XG / payload 1 kg (total of workpiece and tool) / horizontal movement 250 mm / vertical movement 1 mm / conveyor speed 100 mm/sec

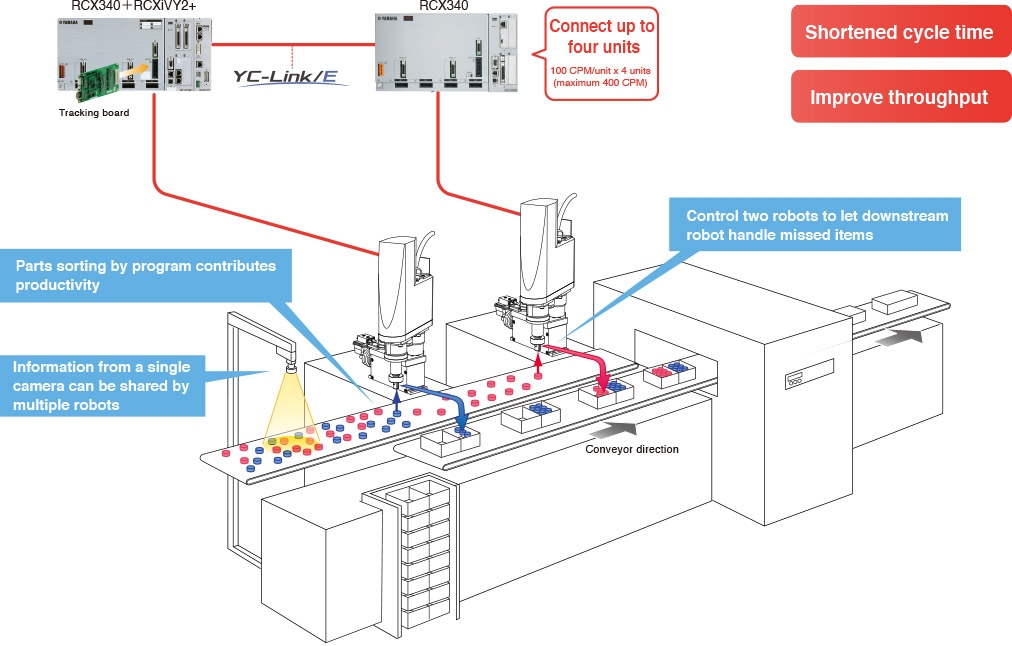

10Improving productivity by controlling multiple robot systems

Various data

Robot Vision System RCXiVY2+

Related contents

- Multi-axis controller RCX340, RCX341

- Introduces the multi-axis controllers, RCX340 & RCX341.

- Reduce setup time by 80%.

- Why does it take surprisingly short time to build up a robot vision system?

- Robot with vision processing function (Application examples)

- Introduces the applications of the robots with vision processing function.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378