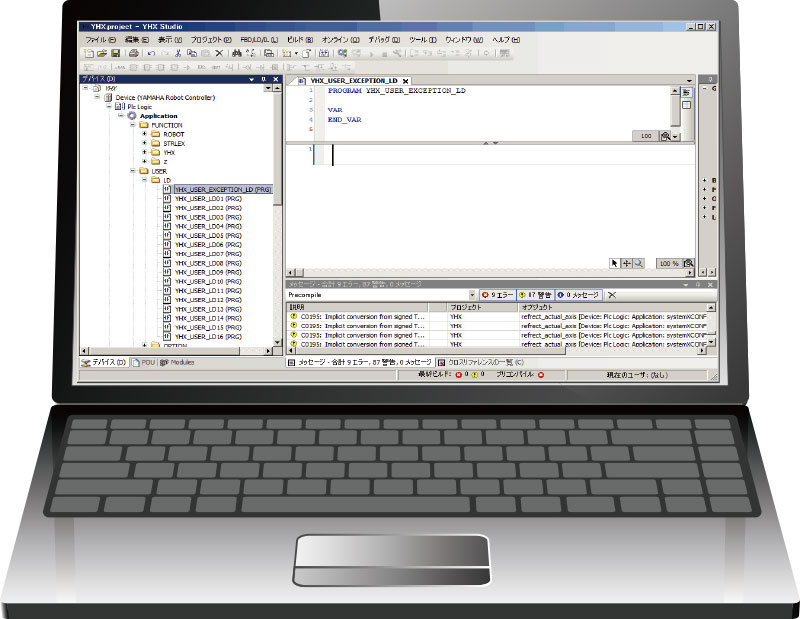

Development environment software YHX Standard Profile : YHX Controller

YHX Studio for Standard Profile is software that is used when the YHX host controller unit of the YAMAHA robot controller YHX series is set up.

Development environment software YHX Studio for Standard Profile

Order model:YHX-SW-STUDIO-SP(KEK-M4990-10)

* No USB key is attached.

| PC operating environment | OS | Windows 7 SP1/8/8.1/10/11 (64-bit version only for all) |

|---|---|---|

| CPU | Intel Core(TM) i5-6200U 2.30GHz or better. | |

| Memory | 8GB or larger | |

| Hard disc drive capacity | 2 GB or more of empty space for destination of installing the YHX Studio. | |

| Communications port | Ethernet | |

| Display | 1920 × 1080 or higher resolution is recommended. | |

| Other | Ethernet cable (Category 5 or better) | |

| Applicable controllers | YHX Host controller unit | |

| Applicable robots | Robots connectable to YHX | |

Microsoft, Windows and Windows 7 are the registered trademarks or the trademarks of Microsoft Corporation in the United States. Other firms’ names and product names appearing in this catalog are registered trademarks or the trademarks of the respective firms or products concerned.

YHX Controller

Related contents

- Controller

- Introduces the robot controller with advanced functions. Select the ideal controller from various command input formats.

- Linear conveyor module LCM-X series

- Significantly improving the space occupancy rate, making better the transport accuracy and increasing the acceleration and deceleration performance, the linear conveyor modules realize higher level transport automatization ever before.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378