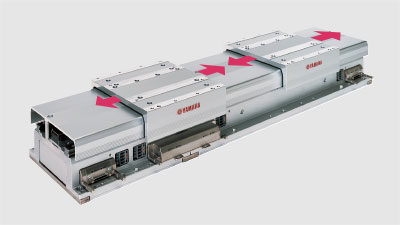

Linear Conveyor Module LCMR200 Comparison of conventional conveyors

Yamaha’s answer to Next Generation of Production Line design

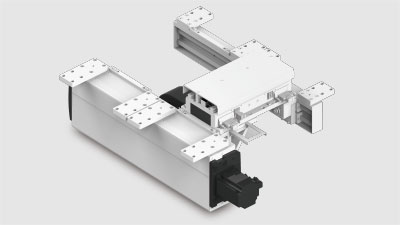

From ordinary “passive flow” to “active position transport”.

By converting conveyor flow into active production process improves profitability.

01Reduce transport time.

<Comparison between LCMR200 and a conventional conveyor>

02LCMR200 vs Conventional Conveyor System

Various data

Linear Conveyor Module LCMR200

Related contents

- Universal Controller YHX series

- YAMAHA's Advanced Robotics Automation Platform realizes cooperative motions and synchronized control among all the robots, peripheral units and devices that make up an automated line.

- Linear Conveyor Module LCM100

- Next generation linear conveyor LCM100 supersedes belt conveyors and roller conveyors.

- Robot Movie Channel

- Yamaha Motor Robot Official Channel

- Shorten takt time by 2 seconds!

- Selection of linear conveyors that defy conventional wisdom for lines.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378