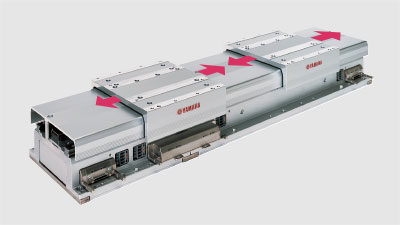

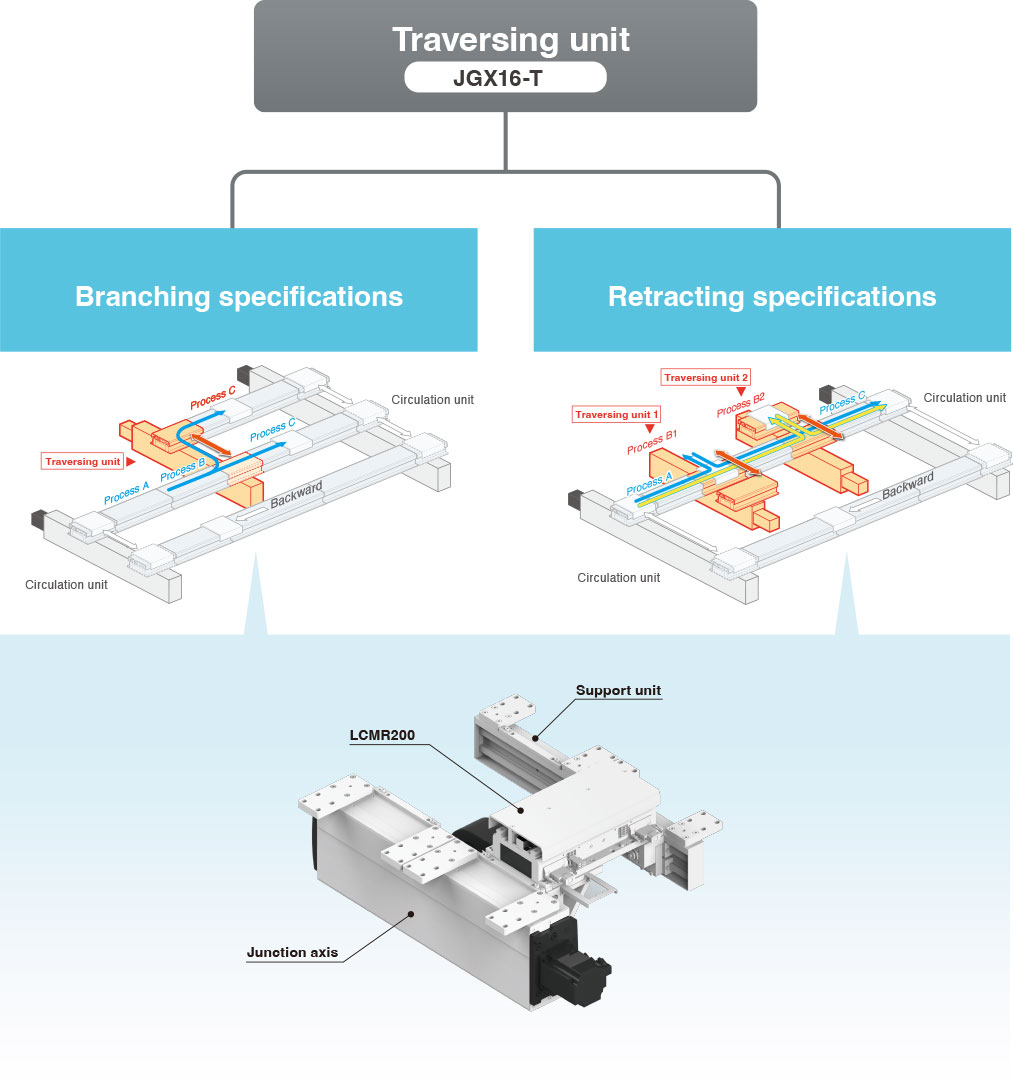

Linear Conveyor Module LCMR200 Traversing unit

This unit can branch the production line or pass the process. Improvement and high efficiency of the production line capacity can be achieved.

Bottleneck process is resolved to improve the throughput.

Sampling inspection and workpiece correction can be performed without stopping the line.

Traversing unit

This unit can branch the production line or pass the process. Improvement and high efficiency of the production line capacity can be achieved.

Bottleneck process is resolved to improve the throughput.

Sampling inspection and workpiece correction can be performed without stopping the line.

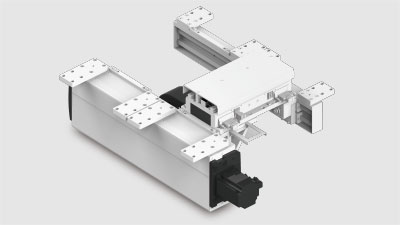

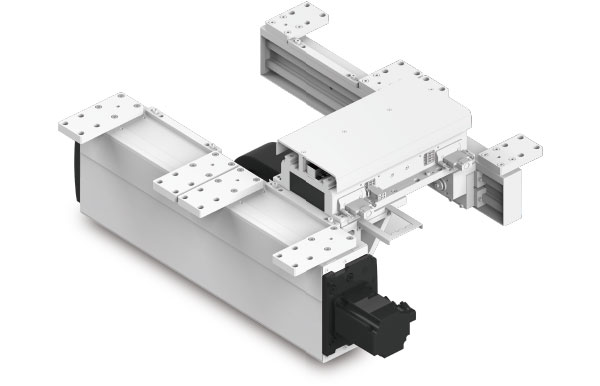

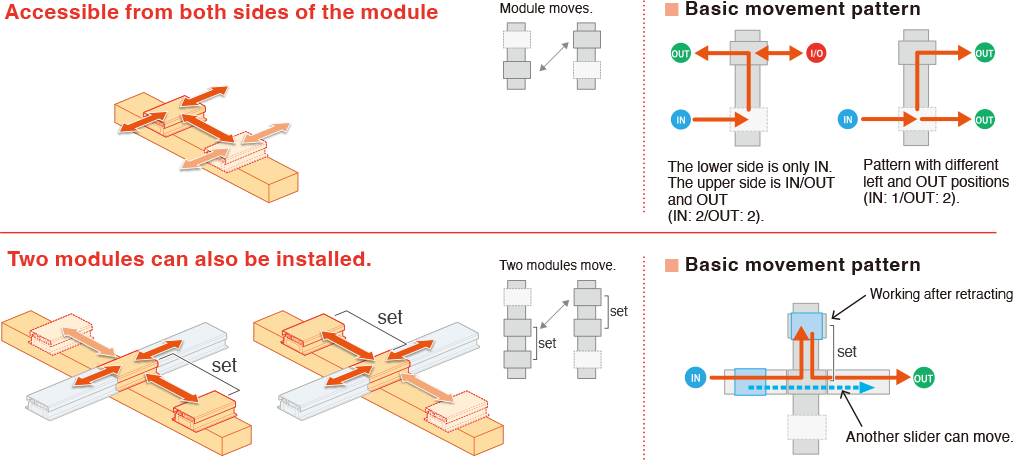

Traversing unit feature

About Traversing unit

Usage example

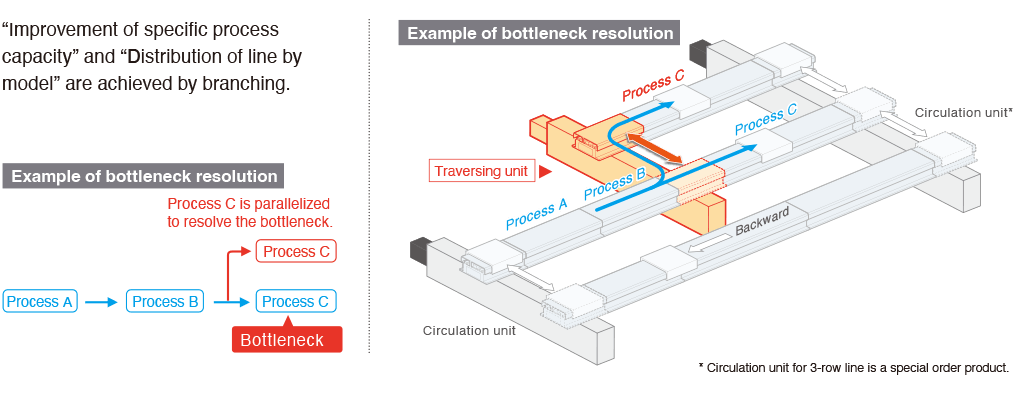

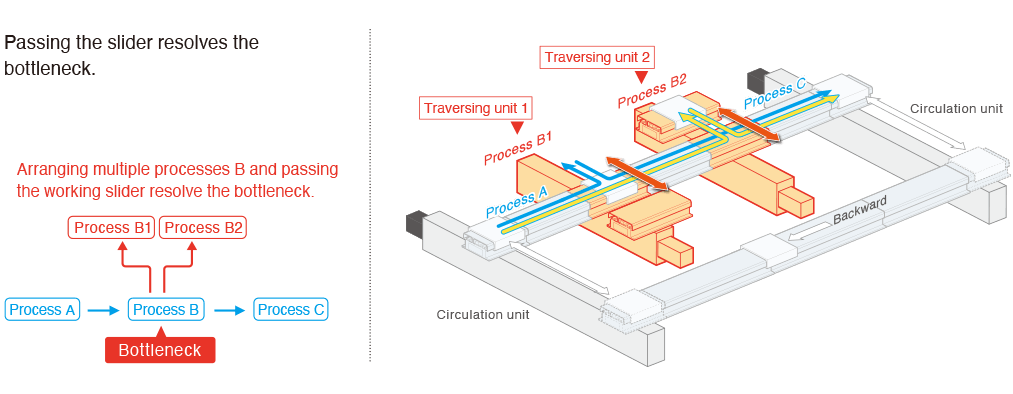

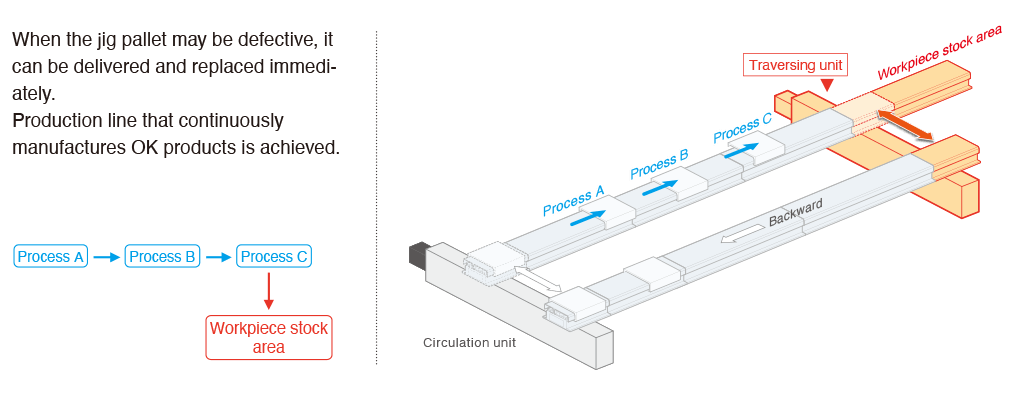

Bottleneck is resolved.The production volume is improved by parallelizing processes that inevitably take time.

Bottleneck is resolved./Multiple models are supported.

Bottleneck is resolved.

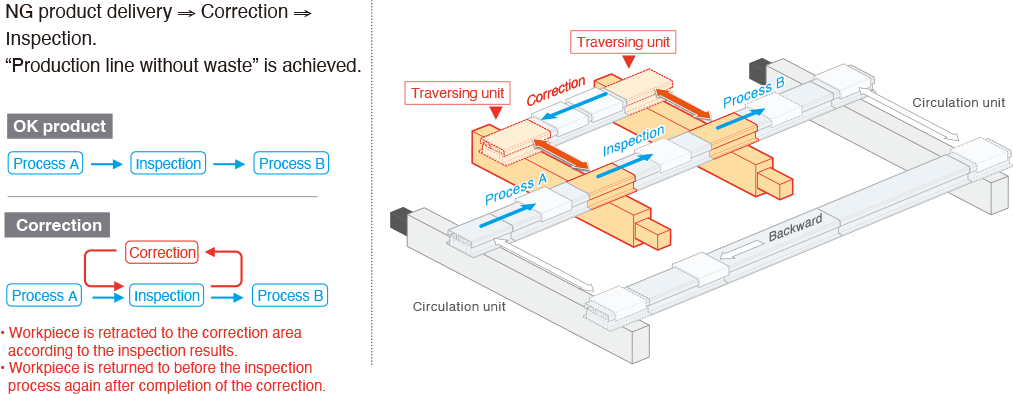

Sampling inspection/correctionThe production volume can be maintained while reducing losses.

Correction

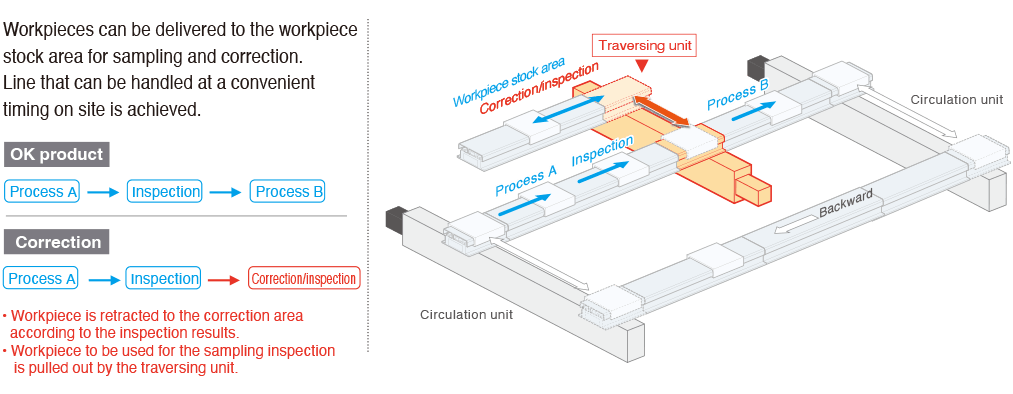

Sampling inspection/correction <Workpiece to be sampled needs to be extracted onto an extension of the line. >

Sampling inspection/correction

Various data

Linear Conveyor Module LCMR200

Related contents

- Universal Controller YHX series

- YAMAHA's Advanced Robotics Automation Platform realizes cooperative motions and synchronized control among all the robots, peripheral units and devices that make up an automated line.

- Linear Conveyor Module LCM100

- Next generation linear conveyor LCM100 supersedes belt conveyors and roller conveyors.

- Robot Movie Channel

- Yamaha Motor Robot Official Channel

- Shorten takt time by 2 seconds!

- Selection of linear conveyors that defy conventional wisdom for lines.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378