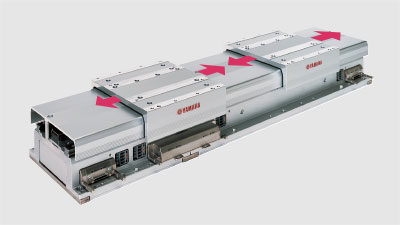

Linear Conveyor Module LCMR200 Structure

Yamaha’s answer to Next Generation of Production Line design

Superior performance that improves the transfer environment.

01No origin process needed

Newly developed high-precision full-range absolute server eliminates the need for return-to-origin. The operation can be started and stopped easily, so there is no time loss even when starting or restarting.

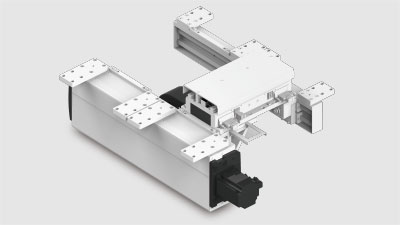

02Easy modular connection with Connecting Plate and Connecting Unit

Mechanical connection by Connecting Plate and signal communicating by Connecting Unit. Simple yet, secured connecting method of modular system.

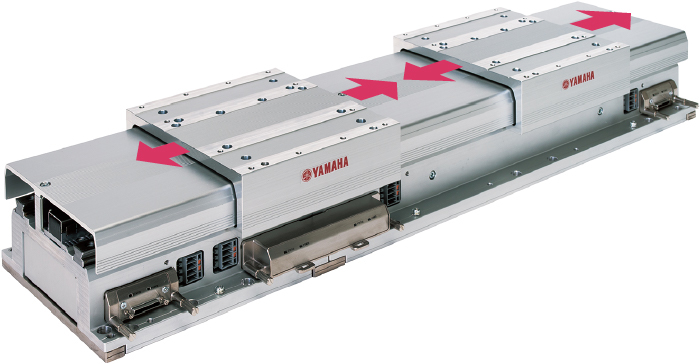

03Saves space through proximity installation of forward and returning modules

<Cable extraction direction can be selected Front Rear >

The cable extraction direction of a module can be selected. When installing on a device, it increases the flexibility of electrical wiring layout. Especially in the horizontal circulation layout, by making the cable extraction direction reverse in the forward and returning modules, the modules can be positioned as close as 200 mm apart at most, and therefore, cycle time reduction is possible at circulation and installation space can be reduced. The LED indicator that shows the module state can be visually checked from both front and rear side of the module.

04Low profile structure

By adopting a newly developed linear motor, the module height is approx. 30 % down compared to LCM100. The space under the frame can be effectively utilized.

05Built-in driver saves electrical wiring

Motor driver is incorporated inside module and entire LCMR200 is controlled by YHX controller through YQLink cable. It also contributes to space saving inside the control panel.

06All the sliders can be operated / programmed independently.

Speed and acceleration can be programmed by each move. All carriages can be controller individually.

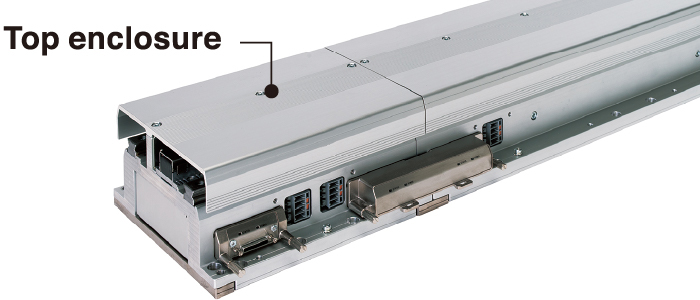

07Top enclosure design for protection.

Top enclosure was designed to protect internal mechanism from any fallen object during line setup process.

08Mechanical tolerance between sliders +/-30 μm (Dowel hole standard)

Due to tis machined accuracy, each carriage has own tolerance at one stopping point, however, LCMR200 can limit the slide machine difference to +/-30 μm, and is suitable for high precision process. As RFID, etc. is not necessary, cost reduction is possible.

Various data

Linear Conveyor Module LCMR200

Related contents

- Universal Controller YHX series

- YAMAHA's Advanced Robotics Automation Platform realizes cooperative motions and synchronized control among all the robots, peripheral units and devices that make up an automated line.

- Linear Conveyor Module LCM100

- Next generation linear conveyor LCM100 supersedes belt conveyors and roller conveyors.

- Robot Movie Channel

- Yamaha Motor Robot Official Channel

- Shorten takt time by 2 seconds!

- Selection of linear conveyors that defy conventional wisdom for lines.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378