Single axis robot positioner TS-X/TS-P

Single-axis robot positioner TS series, providing easy operation, excellent functions, and low price.

TS-X・TS-P

TS-S is a positioner type controller that only performs point trace. No program is needed.

- Operating method :

I/O point tracing / Remote command - points :

255 points - Input power supply :

AC100V / AC200V - Origin search method :

TS-X : Absolute / Incremental - Origin search method :

TS-P : Incremental / Semi-absolute

Feature

01Design that allows a clean installation

Unified installation sizes

Height and installation pitch are unified throughout the series. Units can be installed neatly within the control board.

02Selectable I/O interfaces

Two RS-232C ports provided

Connect support tools

Intuitive operation supports controller design and maintenance.

Daisy-chaining

Two ports can be used to daisy-chain up to 16 units.

Communication commands

Easily understood ASCII text strings can be used to perform robot operations.

Selectable 100V/200V

- The TS-X/P let you select AC100/200V as the power input. (The 20A model is 200V only.)

- The TS-S2/SH is DC24V input.

A variety of I/O interfaces

In addition to NPN and PNP, you can choose CC-Link, DeviceNetTM, EtherNet/IPTM, and PROFINET field networks.

![[CC-Link][DeviceNet][EtherNet/IP][PROFINET]](/business/robot/lineup/controller/ts/img/index/img_02_2_en.gif)

Positioner interface

Functionality has been condensed into an I/O interface with 16 inputs and 16 outputs. In addition to easy positioning, this also includes functionality that enhances interoperability with the control device.

Remote commands

Numerical data can be directly manipulated by using the four-word input and four-word output areas. You can add new direct positioning commands to further unify the data at the control device.

Gateway function

New types of connection are provided to reduce network costs. (CCLink, EtherNet/IPTM, and PROFINET are supported.)

03Positional interface

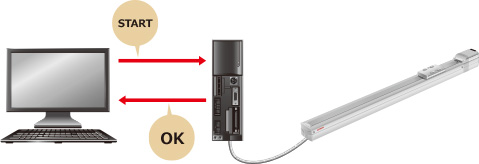

"Positioner function" for easy positioning

You can easily perform positioning operations by specifying the number of a point that is registered in the data, and entering a start command.

A variety of output functions

The TS controller provides a variety of status outputs that are linked with positioning operations. By selecting and using an output appropriate for the scene, this can contribute to cost-saving measures such as making the steps of the control device's program more efficient or by reducing the peripheral equipment.

Consecutive operation, linked operation

By specifying a branch destination, it is possible to execute positioning operations consecutively. Additionally, by specifying linked operation, operation with the branch destination can be executed while changing the speed without positioning stops; this allows control programming to be simplified and takt to be shortened.

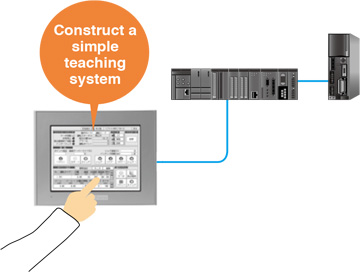

Jog and point teaching functions are provided as standard

Jog movement and point teaching functions are provided as standard for input signals. By linking these with buttons of a touch panel etc., a simple teaching system can be constructed.

04Remote commands

Ideal for unifying data management

Remote commands are functions by which the control device can directly handle data such as points and parameters using the word area of the field network. Numerical data can be operated directly by using the word area. This promotes unification of data management.

05"Gateway function" -- a new way to connect

Decrease network cost

One controller equipped with a field network board can provide unified management of up to four I/O interfaces via a daisy-chain connection. This allows network cost to be decreased while enabling the same type of I/O control as when one board is installed for each unit. (CC-Link and EtherNet/IPTM are supported)

06Daisy chain connection

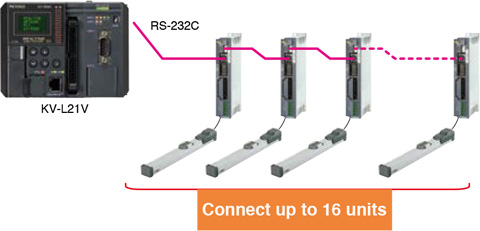

No need to connect or disconnect cables during operation (up to 16 units)

From a single PC, handy terminal, or touch-panel display, it is possible to specify point data and parameters, perform operations, and monitor the status for up to 16 axes on daisy-chained controllers. For everything from design to maintenance, a connection to only the first controller is sufficient; any desired controller can be accessed simply by switching the station number, without having to connect or disconnect cables.

Communication commands

An easily handled command protocol using ASCII text strings supports a wide range of needs from data editing to operation and status monitoring. By daisy-chaining multiple devices, simple multi-axis control can be performed.

07"KEYENCE PROTOCOL STUDIO Lite" serial communication settings software

By loading a TS settings file into PROTOCOL STUDIO Lite, communication settings and main communication commands can be registered automatically. Ladder-less data editing and daisy-chaining can be easily accomplished.

Contact for questions regarding PROTOCOL STUDIO Lite

Daisy-chain connections (up to 16 axes)

Communication with the KV-L21V uses a Yamaha-made communication cable (D-sub type). By using daisy-chain connections, up to 16 axes can be managed together.

Automatic device assignment for each communication command

If the communication type is specified as cyclic, the desired information to be obtained is automatically stored in data memory.

08Touch operator interface "Pro-Face" GP4000 Series

Connecting GP4000 Series made by Pro-face to Robot Positioner, TS-S2, TS-SH, TS-X, TS-P enables you to use a lot of functions as well as basic operations on Touch Operator Interface.

Free download of the program file from the Pro-face home page

Can easily check a state and change settings.

- Check the status (the current position, speed etc)

- Basic operations such as Jog operation, inching operation, return to origin, error reset etc.

- Set, edit, or back up point data and parameters

- Check triggered alarms and detailed descriptions of alarm history

Supports 3 languages

- Supports Japanese, English, and Chinese (simplified, traditional)

Various data

- [TS-S/TS-X/TS-P] basic specifications (182KB)

- [TS-S/TS-X/TS-P] part names / dimensions (214KB)

- Data overview (158KB)

- Point data (158KB)

- NPN type input / output wiring diagram (131KB)

- I/O circuit details (131KB)

- Emergency stop circuit example (131KB)

- I/O Specifications (131KB)

- TS-X / TS-P specification selection table (214KB)

- Regenerative unit RGT/RGU-2 (274KB)

- Ordering method (182KB)

- Accessories (767KB)

Single axis robot positioner TS-X/TS-P

Related contents

- Single axis robots FLIP-X Series (Electric slider)

- FLIP-X series include many models of 6types and 29variations for a wide range of applications.

- Linear motor single axis robots

- Linear motor single-axis robots, PHASER series, utilizing the features of both the shaft type and flat type.

- Single axis robot controller SR1-X/SR1-P

- Introduces the single-axis robot controllers SR1-X and SR1-P.

- Cable

- Dimensional diagrams and model numbers of the robot cables, cable terminals, and connectors are available.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378