2-axis comprehensive controller RCX320

Then newest addition to RCX3 series.

RCX3201 to 2 axis controller

- Controllable robot:

XY-X・FLIP-X・PHASER・YP-X - Certification:

CE - Field networks:

Ethernet/IP, Ethernet, EtherCAT, CC-Link, DeviceNet, PROFINET, PROFIBUS - Operating method:

Programming / Remote command / Operation using RS-232C communication - Points:

30,000Points - Origin search method:

Absolute / Incremental / Semi-absolute

Feature

Real-Time output function for Preventive Maintenance.

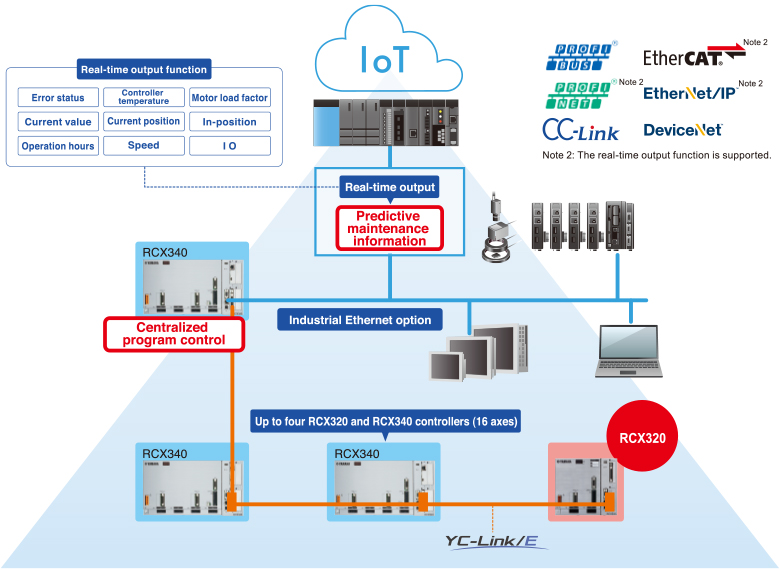

01Industrial Ethernet option Real-Time output functionNote 1

When the industrial Ethernet option (Ethernet/IP, EtherCAT, or Profinet) is selected, the information necessary for the predictive maintenance such as error status, current position, current value, motor load factor, operation hours, and others can be output in real-time to contribute to achievement of the "non-stop production line".

Note 1: The 4-axis controller "RCX340" also supports this function.

Easy and user-friendly operation system

02Economical solution for 6 axes robot setup.

By connecting RCX340 4-axis controller through YC Link/E, total of 6 robots can be operated.

03PBX with USB port for backup.

Simple and easy operation for adding function or editing work. Storing backup data is a simple task.

04The CPU processing capacity is increased approx. three times.

The CPU processing capacity is approximately three times faster than that of the conventional model RCX221/222. The control performance such as operation tracking or internal process time is improved greatly.

05Convenient LED Display for Error Status.

The operation status is displayed on the "7-segment LED display" located on the front panel of the controller. If an error occurs, the relevant error message is displayed. The error status can visibly recognized without connecting the programming box.

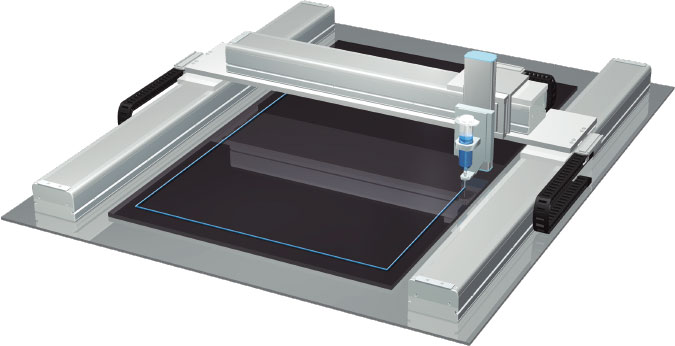

06RCX320 supports all 2-axis robots from small to large.

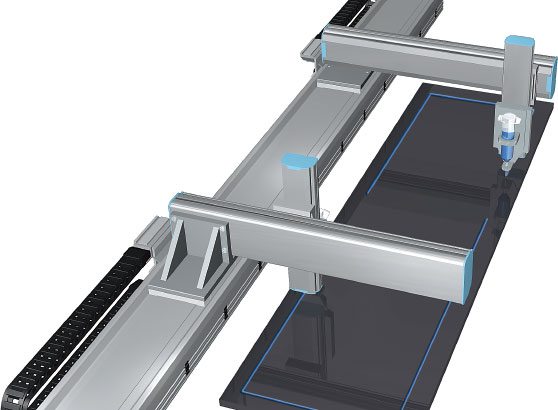

RCX320 is designed to operate Yamaha’s all 2-axis robot systems with AC servo motor or linear motor. Controls two Flip/Phaser axes or all XY 2-axis systems.

07Ideal for dual synchronized robot systems.

The dual robot that performs the synchronous drive between two axes can be easily controlled by one RCX320 controller.

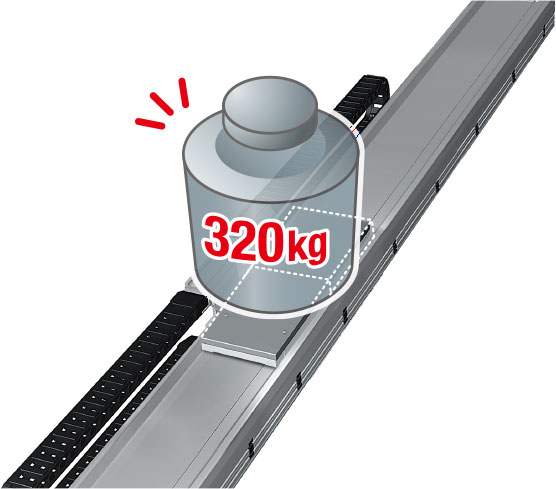

08Up to 320 kg can be controlled by one RCX320 controller.

If two sliders of Phaser dual system are connected and synchronized, its total payload capacity will become 320 kg (MF75D system).

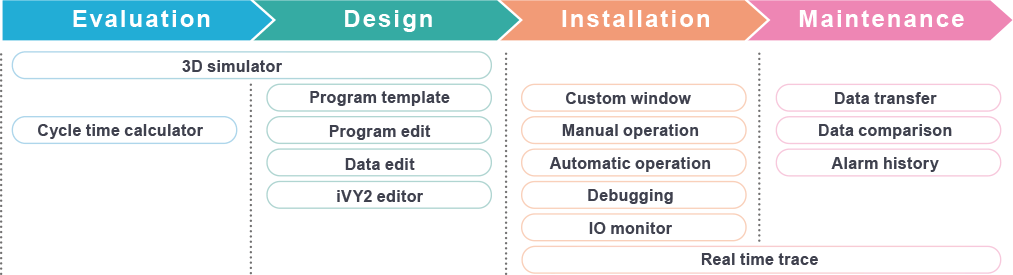

09PC Programming Software “RCX-Studio 2020”(Common to the RCX340)

Both RCX340 and RCX320 run with RCX-Studio 2020. New functions such as 3D simulator function and program template (program template automatic creation function) are added for ease of user operation.

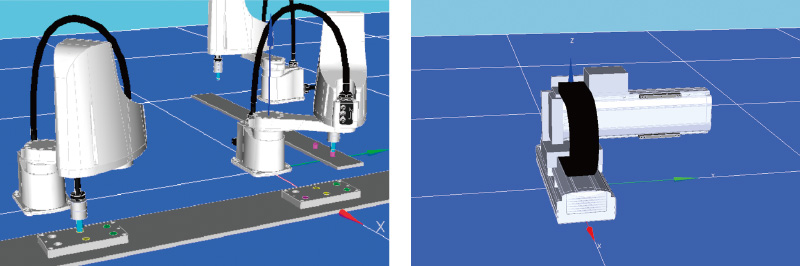

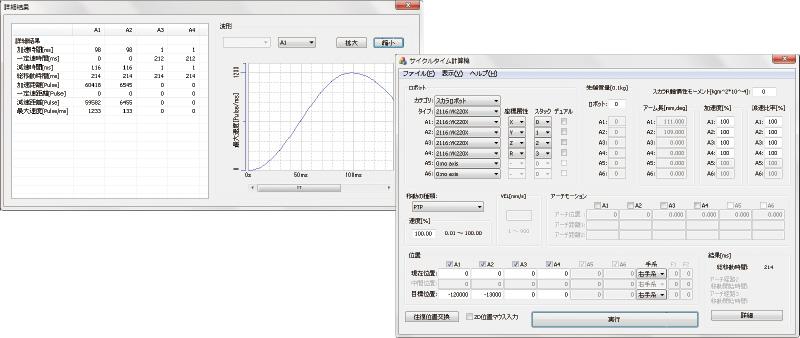

3D simulator

Layout can be verified beforehand without connecting robot.

Robots and peripheral devices are displayed in 3D, and the robot operation is simulated on PC. (This function supports SCARA and Cartesian robots.)

▶ Robot layout, teaching, and debugging can be performed.

▶ Physical interference between the robot and peripheral device can be checked before operation is started.

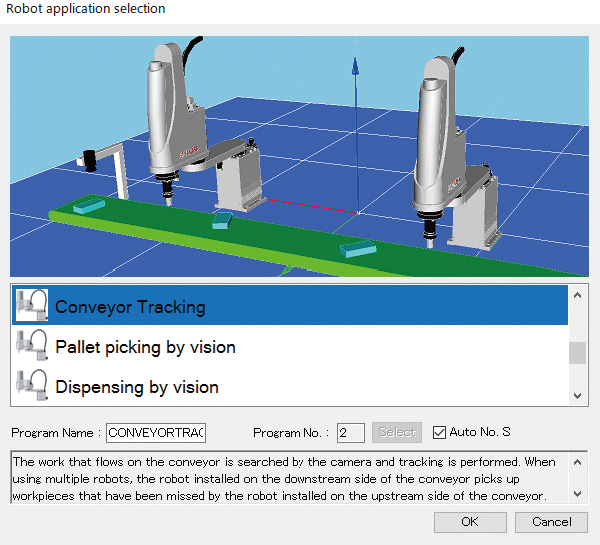

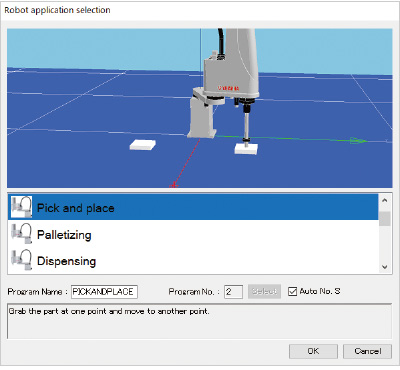

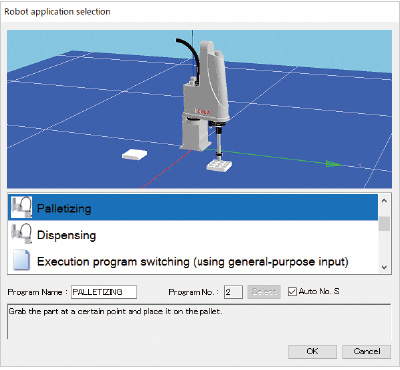

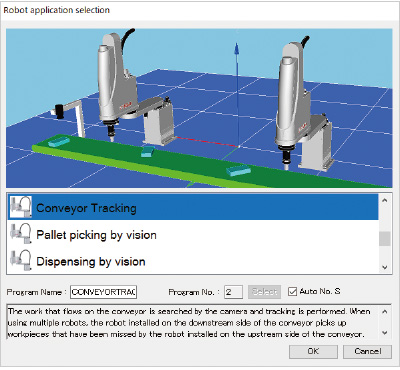

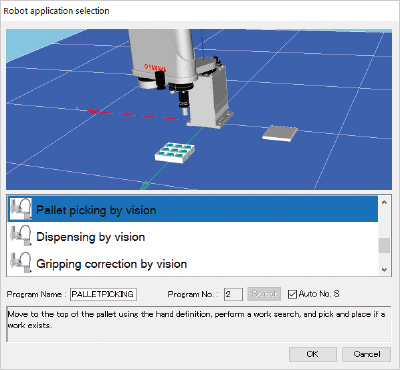

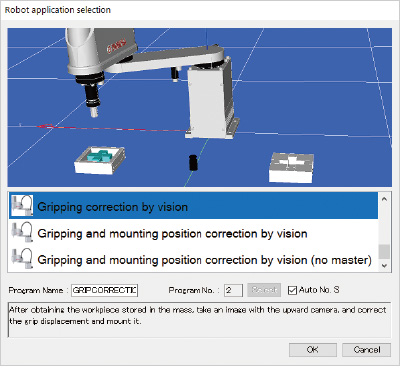

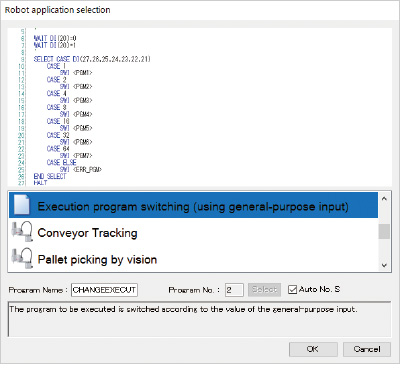

Program template (Program template automatic creation function)

Program creation time can be shortened greatly.

Program templates for 10 types of applications are incorporated. Just following the steps to perform the operation creates a program template automatically.

Supported applications

- Pick & place

- Palletizing

- Dispensing work

- Execution program switching

- Conveyor tracking

- Pallet picking using vision

- Dispensing with vision

- Gripping deviation correction using vision

- Parts orientation adjustment on the fly with vision

- Parts orientation adjustment on the fly with vision (without master)

Program automatic conversion function

Controller program for RCX240 and earlier is converted to that for RCX3 series.

Other functions

All useful features from RCX-Studio Pro are succeeded to help supporting from startup to maintenance.

More enhanced expandability

10Enhanced field network support and option function

Six types of internal field networks such as EtherNet/IP, EtherCAT, CC-Link, DeviceNet, PROFINET, and PROFIBUS are supported. The RS-232C and Ethernet ports are installed as the standard ports and the option functions such as the gripper and vision system are also supported, allowing you to construct a system suitable for the needs.

11Synchronized control of multi-axis robots

Use of the inter-controller communication "YC-Link/E" makes it possible to control multiple robots such as Cartesian robots and SCARA robots synchronously. The YC-Link/E can be executed by the program of only the master controller. This contributes to great reduction of the system startup time. The "RCX320" and "RCX340" controllers support both the master and slave specifications, allowing you to construct a system flexibly. Note. Up to four "RCX320" and "RCX340" controllers can be connected by the inter-controller communication "YC-Link/E".

Improvement of basic performance

The basic performance is greatly improved when compared to the conventional "RCX221/222" controllers.

Various data

2-axis comprehensive controller RCX320

Related contents

- Multi-axis controller RCX340, RCX341

- Introduces the multi-axis controllers, RCX340 & RCX341.

- Field Networks (RCX)

- Robot controller RCX series is applicable to the field networks CC-Link, DeviceNet, Profibus, Ethernet, EtherNet/IP.

- Cartesian robots

- A wide variety of Cartesian robots, XY-X series, with appropriate performance meeting the customers' needs.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378