LOW COST HIGH PERFORMANCE SCARA ROBOT YK-XE

For improved efficiency and reliability in production at affordable price

LOW COST HIGH PERFORMANCE SCARA ROBOT YK-XE

Efficiency In Production

For improved efficiency and reliability in production at affordable price

- Arm length:

400mm to 710mm - Maximum payload:

4kg to 10kg

Feature

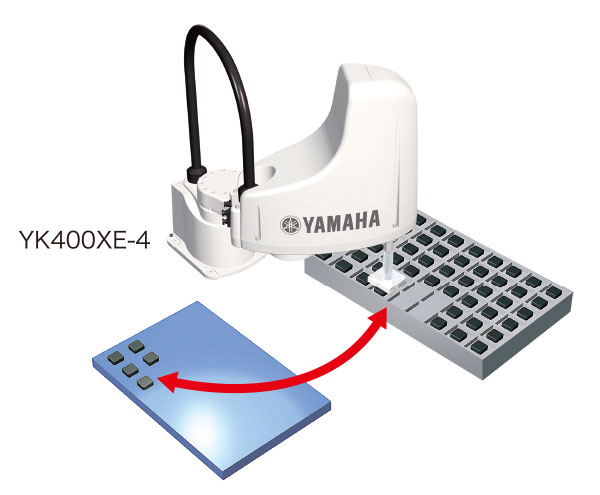

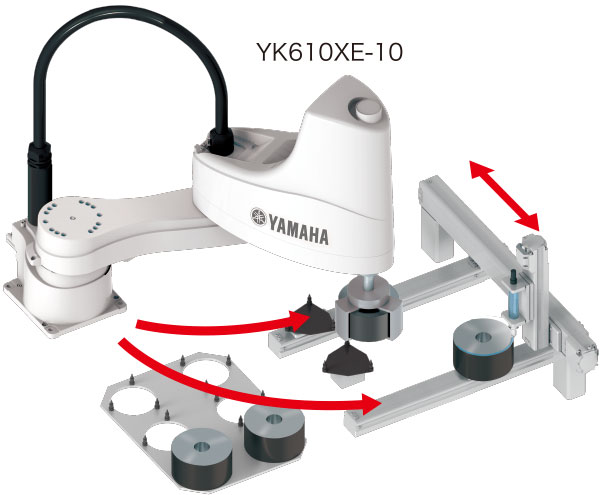

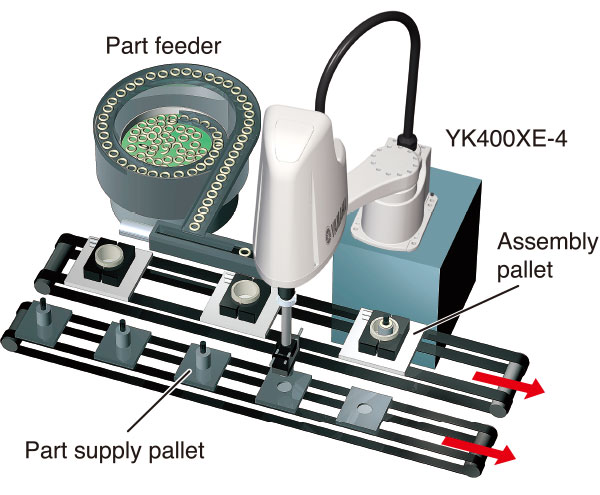

01Optimal for transfer and assembly of automotive parts

02Improvement of productivity by high-speed operation

By reviewing the arm structure, the vibration is reduced and the motion is optimized to shorten the standard cycle time. High-speed, less-vibration, and agile operation contributes to improvement of the productivity.

03For a wide variety of applications Maximum payload 4kg to 10kg

Assembly

Packaging

Palletizing

Sorting

Inspection

Labelling

Soldering

The models support a wide variety of fields such as assembly work that requires a high precision or food sorting work that requires a high-speed operation. As the maximum payload is 10 kg, heavy workpieces such as automotive parts can also be supported.

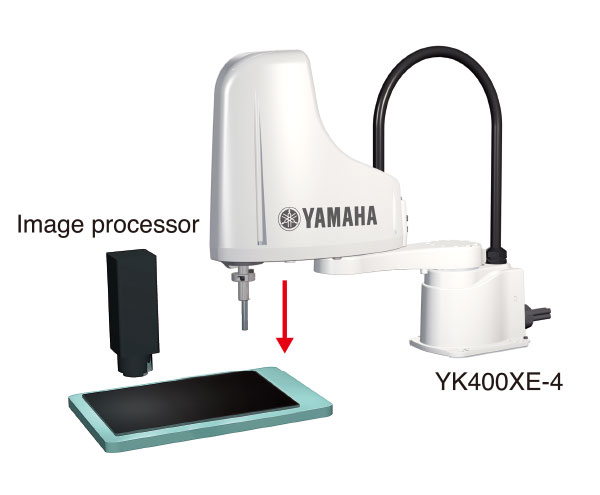

04Application Examples

05Affordable Price and Improved Performance

Both the high operation performance and affordable price are achieved. Production equipment with high cost performance can be constructed.

06Improved User Interface

Enhanced size and numbers of air tubes and user I/O for end effectors. Tubes and wires are positioned for easy layout and reduced risk of disconnection. (YK610XE-10 and YK710XE-10)

07In Yamaha YK-XE series Acceleration/Deceleration is optimized automatically

The optimal acceleration and deceleration are automatically selected from the arm posture at the time of operation start and the arm posture at the time of operation end.

The motor peak torque or the tolerable peak torque of the speed reducer is not exceeded by inputting only three parameters*.

The full power of the motor is always output to maintain the high acceleration/deceleration.

* Payload, R-axis moment of inertia, and offset amount of R-axis moment of inertia

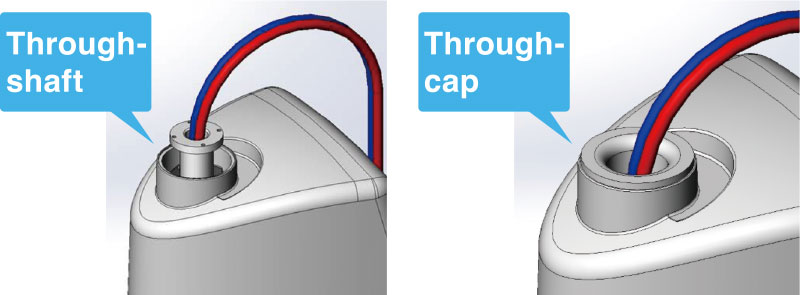

08Through-shaft and through-cap have been added. (Option specifications)

NEWAlso NEW compatible with YK400XE-4

“Through-shaft” or “through-cap” option for wiring and tubing that is convenient to run the air tubing and wiring can be selected. The wiring and tubing routes can be investigated easily without designing and manufacturing a stay for installing the wiring and tubing. In addition, by passing the wiring and tubing through the inside of the main body, worries about wire breakage or disconnection are reduced during operation.

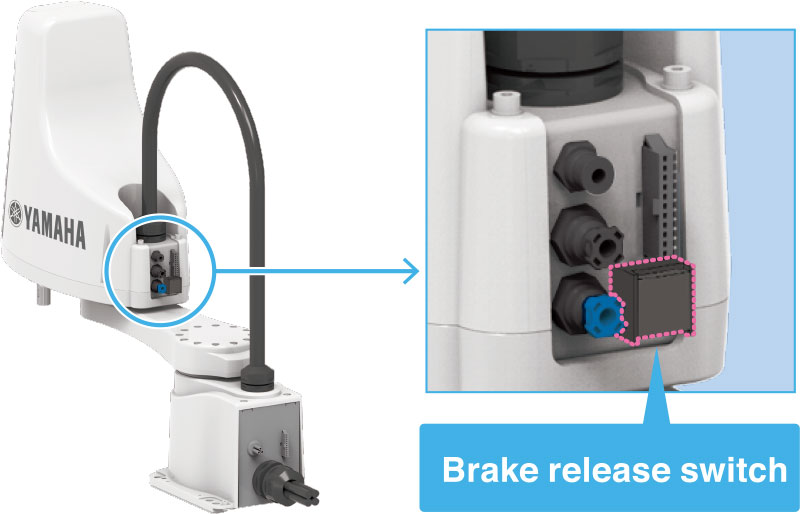

09Brake release switch is selectable. (Option specifications)

In the emergency stop state, the Z-axis brake is released and the Z-axis can be moved up or down while the brake release switch is held down. Releasing the switch applies the brake to the Z-axis. This improves the convenience during installation adjustment.

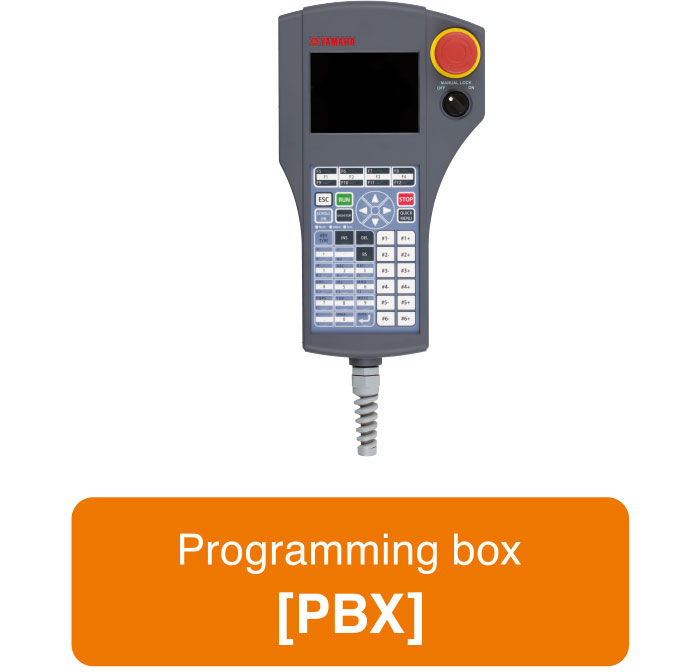

10Easier operation in combination with the RCX340 controller

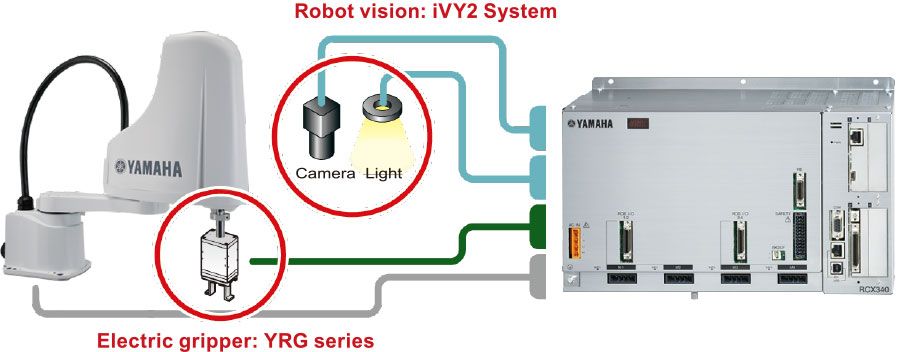

RCX340 comprehensive controller brings out maximum potential of YK400XE robot system. Optional integrated vision system “iVY2” provides simplified image processing. Choice of PC Programming Software or Teaching Pendant available.

11Simple and Easy integration of Vision System

Robot controller with vision and gripper interface

12Compatible with various field networks

The robot is compatible with full field networks such as CC-Link, EtherNet/IP™, DeviceNet™, PROFIBUS, PROFINET, and EtherCAT.

13SCARA robot Accumulated achievements since 1976

Originally developed in-house to provide durable and accurate motion control in harsh environment of motorcycle manufacturing, Yamaha's SCARA robots have been proven over many years in a variety of fields.

* The product release was 1984.

Various data

LOW COST HIGH PERFORMANCE SCARA ROBOT YK-XE

Related contents

- SCARA robots

- The wide reach and payload ranges from 120 mm to 1200 mm and from 1 kg to 50 kg, allowing for precise adjustment of the robot to your application

- Small type SCARA robots

- Introduces the small size SCARA robots.

- Multi-axis controller RCX340

- Introduces the multi-axis controllers, RCX340.

- SCARA robots (Application examples)

- Introduces the applications of the SCARA robots.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378