Support software RCX-Studio 2020 3D simulator

Programming software for RCX 3 Series Controller

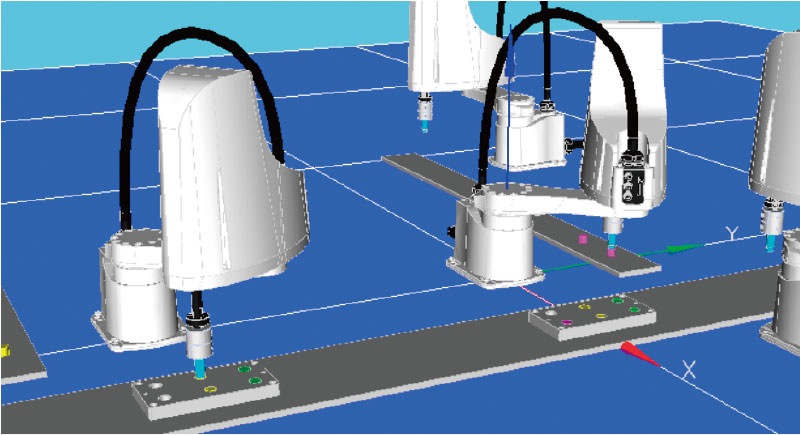

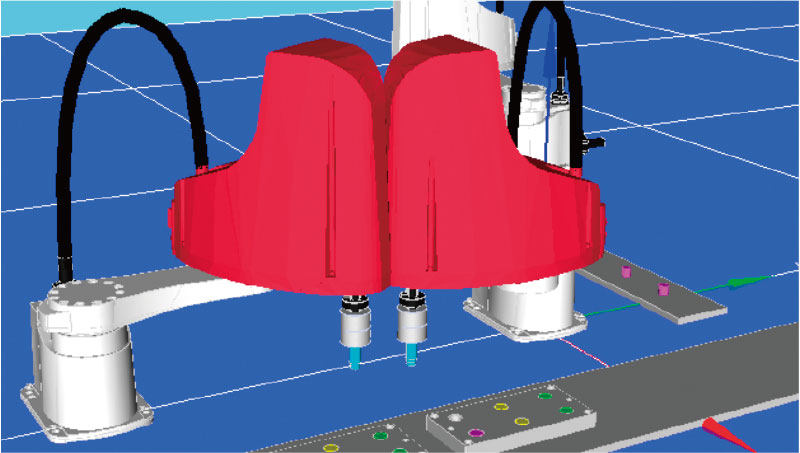

3D simulator

Robots and peripheral devices are displayed in 3D, and the robot operation is simulated.

3D CAD Data imported

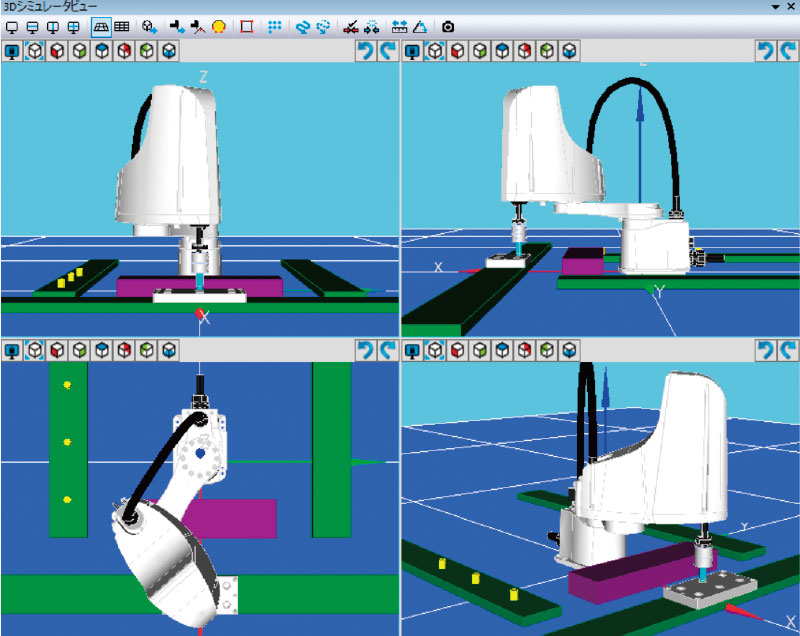

■ Multiple robots are supported (up to 4 robots).

Importable data

STL, Wavefront OBJ, VRML2.0, STEP *

* Only Pro version is supported. Supported format: AP204, AP214

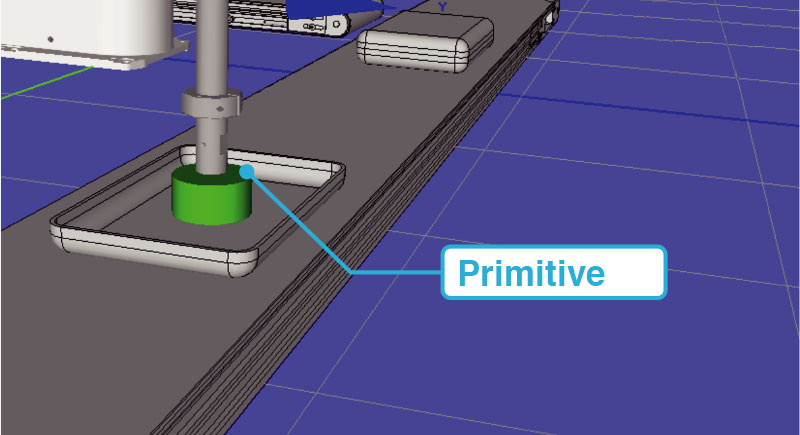

Peripheral devices are displayed using primitives.

■ Peripheral devices and workpieces can be displayed using simple shapes (primitives).

Teaching virtual robot on screen

■ Teaching of the current position can be performed by moving virtual robots using the jog or mouse operation.

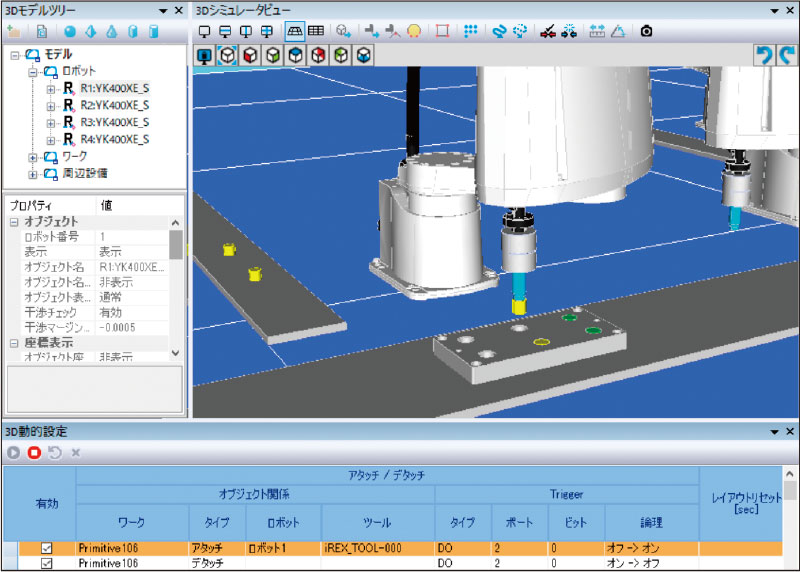

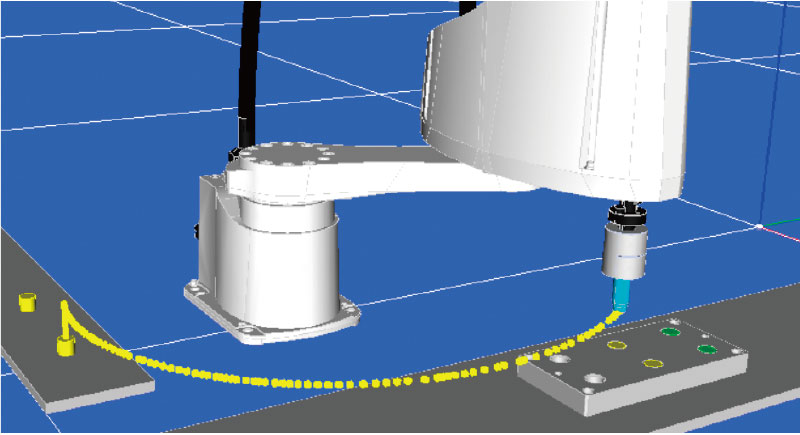

Operation area is verified by tracing the movement of end-of-arm effector and parts

■ Visually tracing robot move

■ Movement of workpiece and end effector can be displayed.

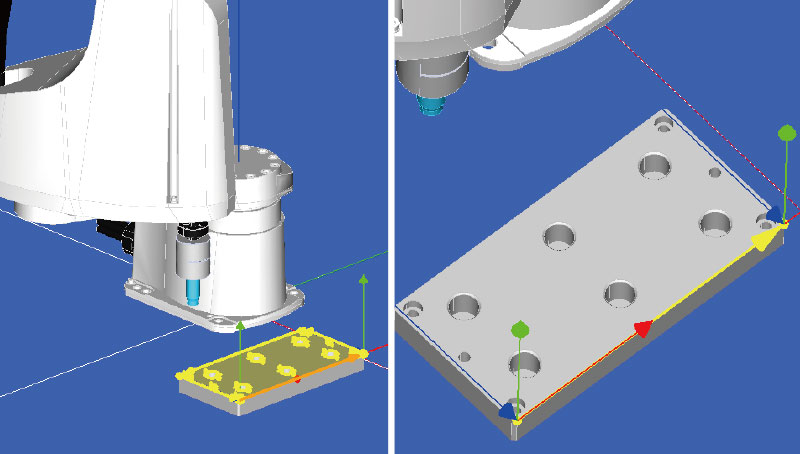

Interference with the production units is checked to avoid collision with other devices.

■ Interference between the robot and peripheral device is checked.

* Interference check is performed at the screen drawing timing. Therefore, the interference may not be detected depending on the execution environment and operation status of the software. To perform the accurate check, it is recommended to decrease the operation speed of the robot and perform the check several times.

Multi-angle View (Screen division function)

■ Layout can be checked from multiple viewpoints at the same time.

Video capture*

■ The simulation results are output as a video.

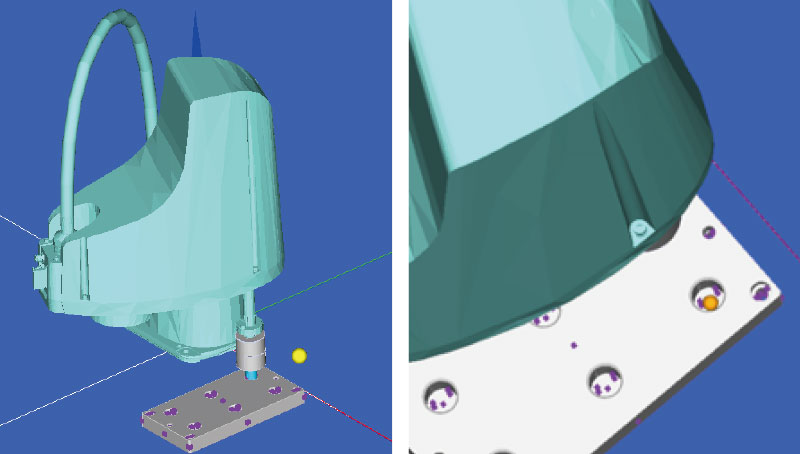

STEP data file can be imported.

Feature points with STEP file data are displayed.

Feature points with STEP file data are displayed.

For the STEP data, feature points of the 3D CAD data are displayed. Clicking the feature point moves the robot.

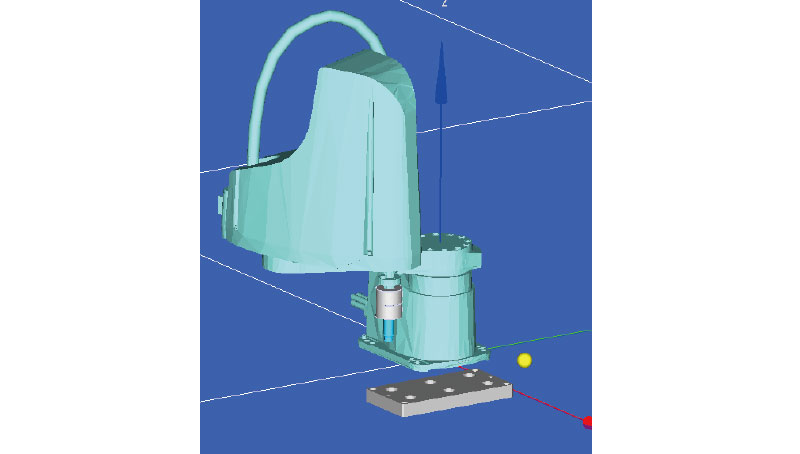

Feature points of 3D CAD models are not displayed.

Feature points of 3D CAD models are not displayed.

For data other than the STEP data, feature points of the 3D CAD data are not displayed.

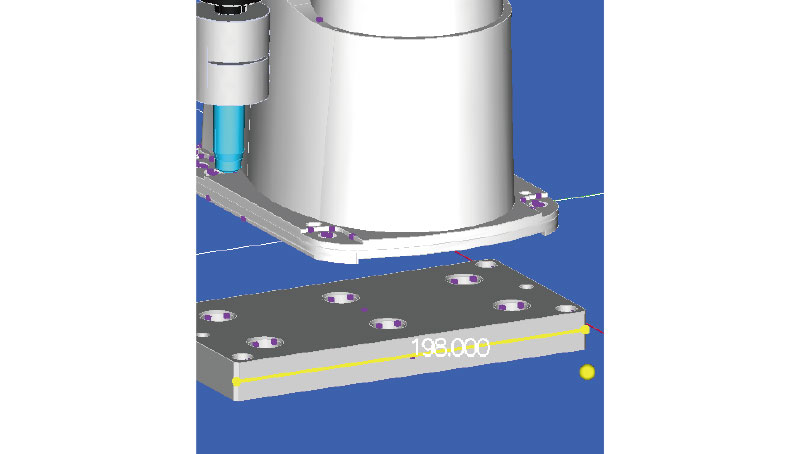

Measurement of distance and angle

With STEP file data the distance and angle can be measured using the feature points on the edge.

Creation of edge point data

With STEP file data the feature points on the edge can be converted into the point data.

Support software RCX-Studio 2020 3D simulator

Related contents

- 2-axis controller RCX320

- Introduces the 2-axis controllers, RCX320.

- Multi-axis controller RCX340, RCX341

- Introduces the multi-axis controllers, RCX340 & RCX341.

- SCARA robots

- The wide reach and payload ranges from 120 mm to 1200 mm and from 1 kg to 50 kg, allowing for precise adjustment of the robot to your application

- Robot Vision System

- Use of ROBOT vision system "iVY system" makes it possible to propose new production lines that do not require workpiece positioning and teaching.

Robotics Business Unit

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Chūō-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone +81-53-525-8350 /

Facsimile +81-53-525-8378