【Discontinued Product】 D×D Printer YSP20 Feature

BUILT-IN HIGH–SPEED & MULTI-FUNCTIONS SURPASS ALL PREVIOUS LIMITS!

Ideal for High-Speed Multi-Function Printing

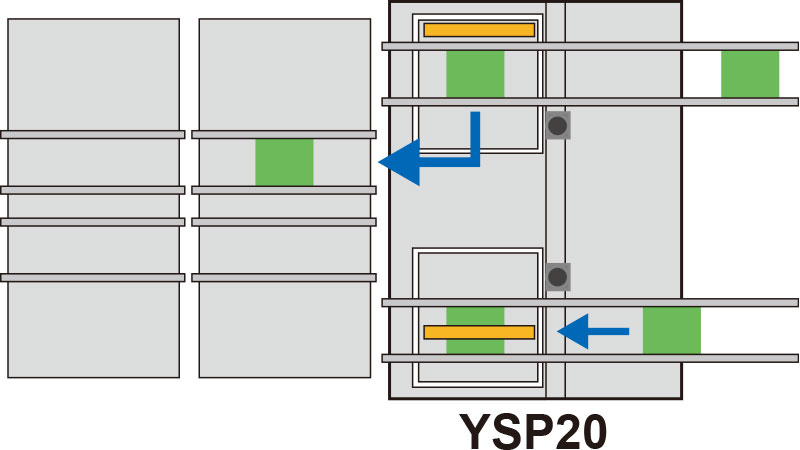

With dual stage & dual stencil

Printing has a line tact time of approximately 5 seconds. More than doubles the YSP productivity.

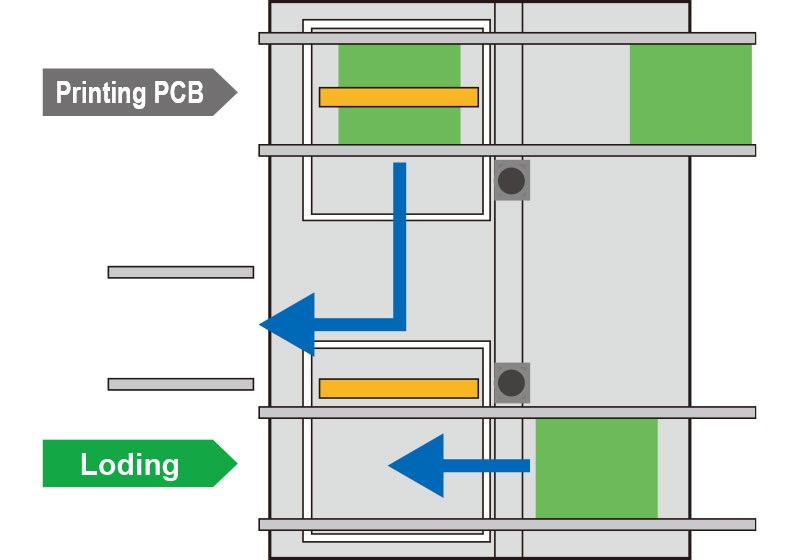

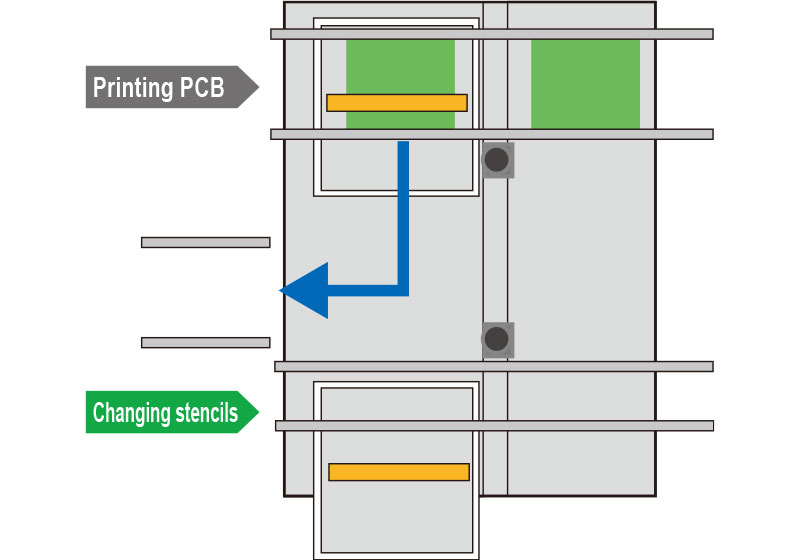

Non-stop setups & changeovers

One side sets the stencil backup while other side prints PCBs.

Fully compatible with YAMAHA dual lane system

Internal traverse function handles all dual-lane and single-lane types as a standard feature.

Delivers High-Quality & High-Accuracy Printing

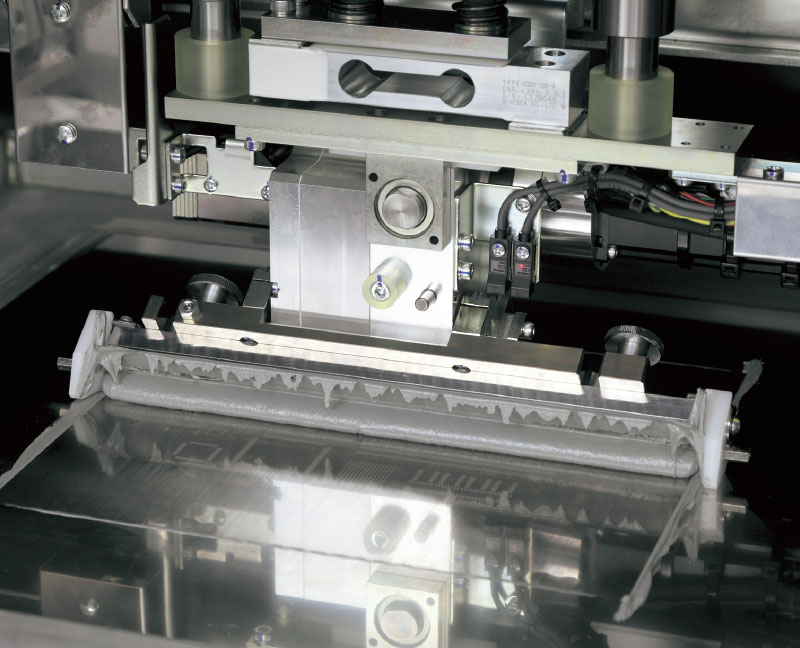

YAMAHA’s original 3S head[3S:Swing Single Squeegee]

Program change squeegee attack angle and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

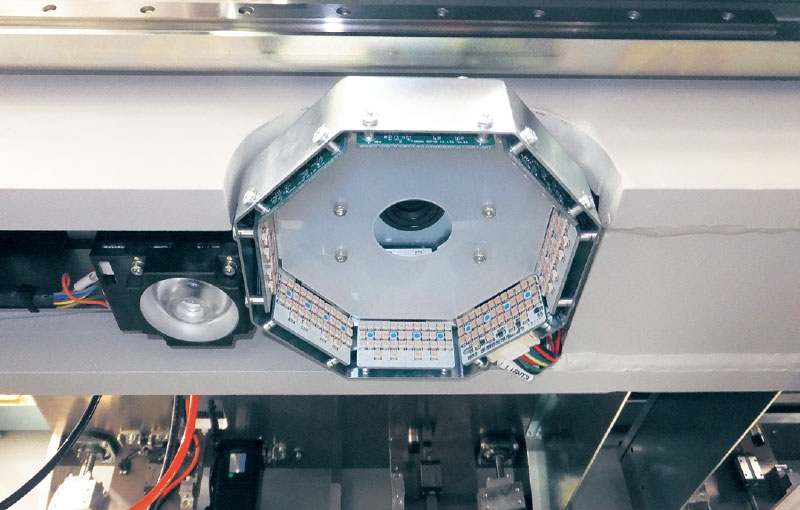

Printing inspection function(option)

Dedicated camera does full main line inspection. Feedback results are used in automated overlay printing and stencil cleaning.

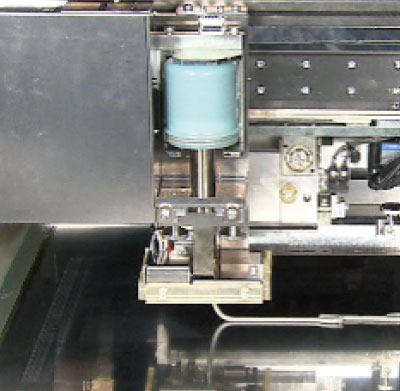

PSC system (option) for stable printing[PSC:Print Stability Control]

This function stabilizes the cream solder rolling radius that affects print quality. The PSC function shortens the setup time and cuts solder loss. PSC is also compatible with non-stop production operation.

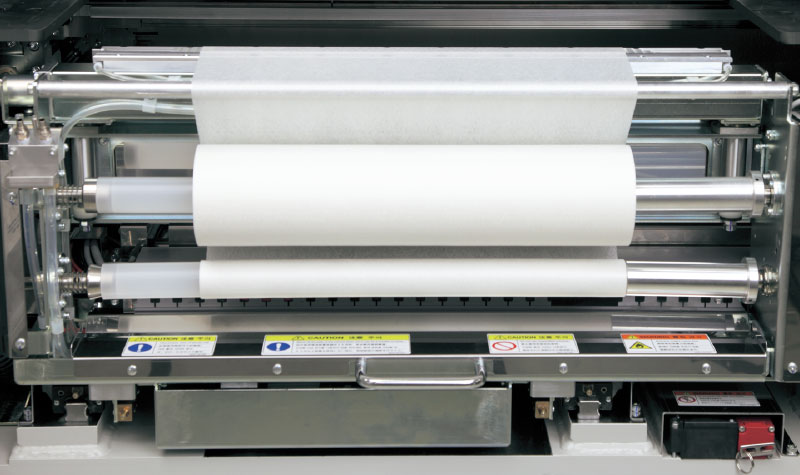

Auto cleaning system

High efficiency cleaning system is a standard feature. New system design makes for quieter operation.

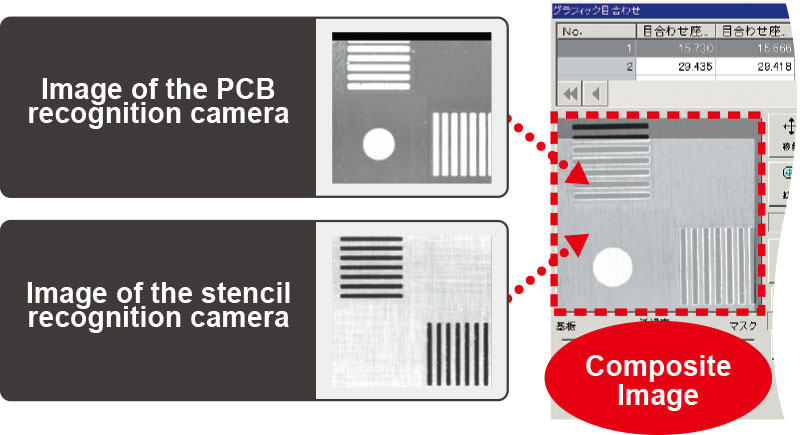

Graphic layer base alignment function

Composite display made from 2 camera images allows easy and precise alignment of PCB and stencil positions.

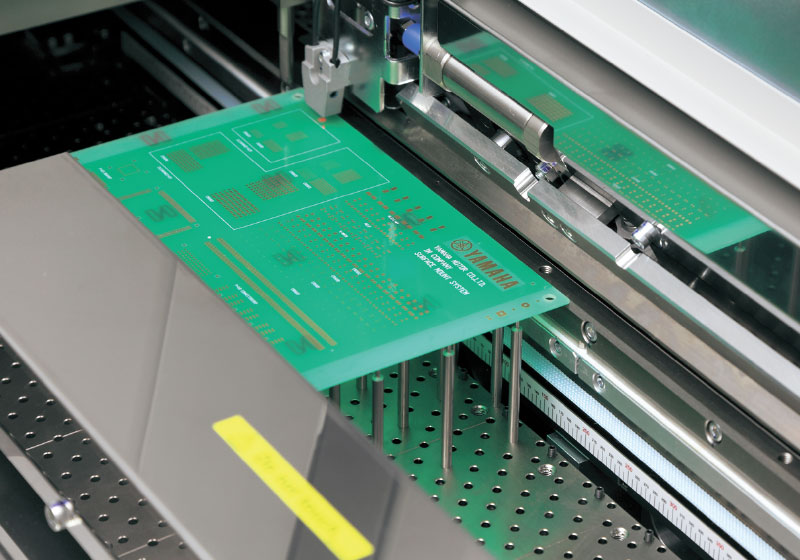

Handles Large PCB & Stencils

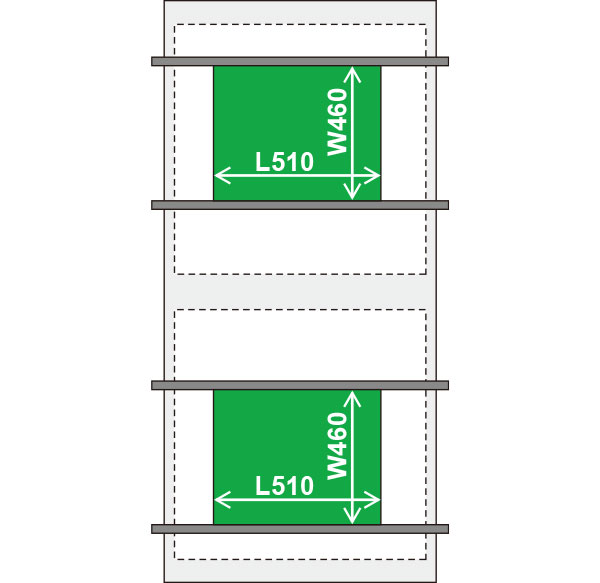

Handles large PCBs

This model is designed to handle larger PCBs up to L510 × W460mm, expanding its capacity to accommodate collective substrates, LCD PCBs and industrial-use PCBs.

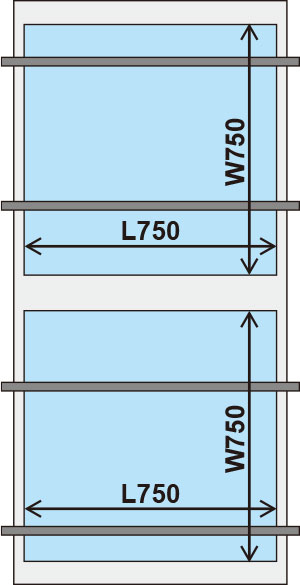

Handles large stencil sizes

Both front and rear stages handle large stencils to a maximum size of L750 × W750mm. 4 types of stencil sizes can easily change by a simple operation.

Superb Operability & Full Range of Options

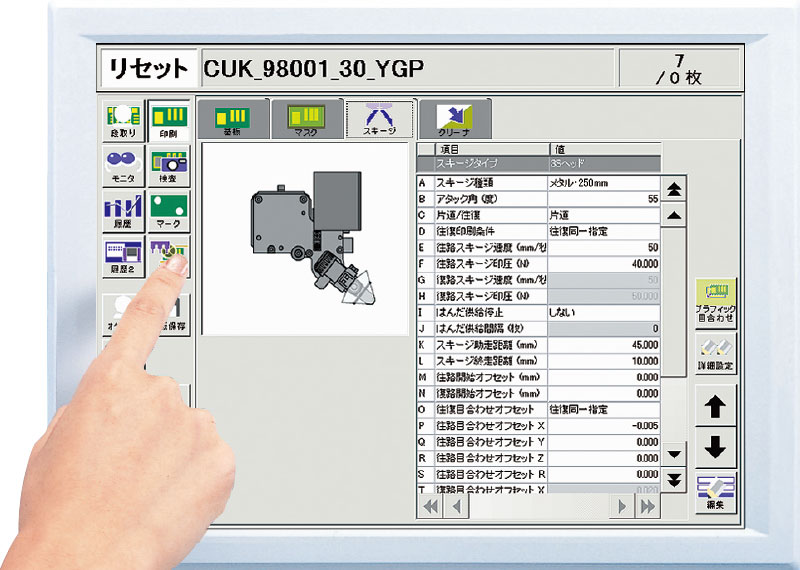

Touch panel

Smooth and simple operation via easy-to-see and easy-to-use interface Displays text in 4 languages: Japanese, English, Chinese, Korean.

Options

- Print inspection camera

- Print stability control (PSC)

- Left to right conveyor

- PCB vacuum suction system

- Temperature control unit

- Transformer for Temperature control unit

- Solder remaining quantity detection

- UPS system

- Double squeegee head

- IT option

Related contents

- Product

- Introduce our product lineup, including surface mounters, solder printers, and visual inspection machines.

- Showroom

- Find and explore SMT Smart Showroom or Virtual Showroom

- Intelligent Factory

- IoT/M2M Integration system - System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.