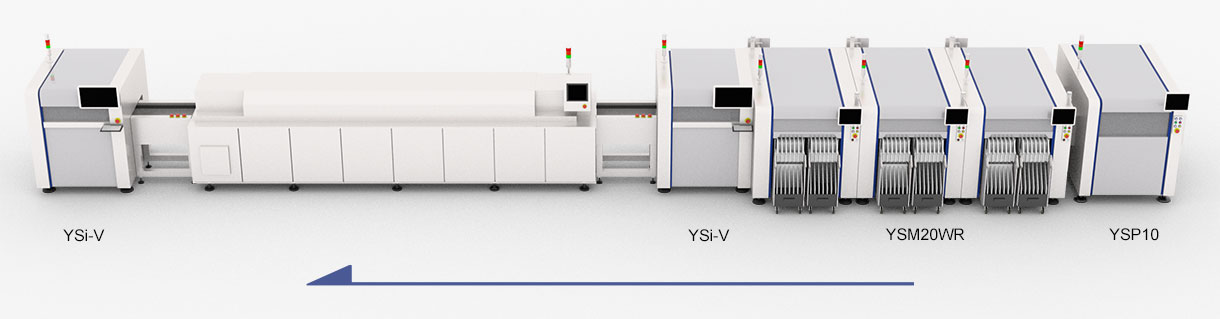

Proposal for production line of industrial equipment

High-speed and high-accuracy line that mounts components on large/heavy PCBs

Examples of customers’ problems and needs

Examples of customers’ problems and needs

Dealing with large PCBs

High-speed and high-accuracy machines that mount components on large/heavy PCBs are needed.

Dealing with odd-shaped components

Dealing with odd-shaped or tall components causes the operation to lose time balance and prevents increased productivity.

Changeover work

Changeover work including replacement of feeder carriages consumes much work and time generating a machine down-time.

Solution

Solution

Dealing with large PCBs

(YSM20WR): High-speed high-accuracy mounting with a PCB size up to W742×L810mm and weight up to 10kg can be performed as a standard.(We offer custom designs for special equipments)

Dealing with odd-shaped components

(YSM20WR): The HM head can handle a wide variety of components from 0201mm to W55 × L100 mm.

Yamaha’s original technique of dramatically shortening the head traveling distance and dual-stage mounting enables high-speed mounting of odd-shaped or tall components.

Changeover work

(YRM20): A relatively large number of installed feeders minimizes the changeover work count. Using easy-to-handle compact small carriages increases the work efficiency.

Expected introduction effects

Expected introduction effects

Dealing with large PCBs

This line can perform high-speed and high-accuracy component mounting on any type of PCB. It allows to make flexible designs.

Dealing with odd-shaped components

Producing various types of products is available. It maintains the cycle time for a wide variety of product types, which makes it possible to realize high productivity as a whole, In spite of the fact that it is handling odd-shaped or tall components.

Changeover work

This line reduces the burden of changeover work on operators, leading to improvement in machine operation rate and reduction in operational errors.

Related contents

- Product

- Introduce our product lineup, including surface mounters, solder printers, and visual inspection machines.

- Intelligent Factory

- IoT/M2M Integration system - System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.

- Showroom

- Find and explore SMT Smart Showroom or Virtual Showroom