Awards

Introducing the stories behind Yamaha Motor's technologies.

- Search Tab ››

- Year

- Award

- Technology

- Engine

- Electronic Control

- Chassis

- Combustion

- Drivetrain/

Propulsion - Vibration

- Manufacturing

- Production

- Material

- Riding/Driving Aid

- Fuel Cell

- Environment

- Transport

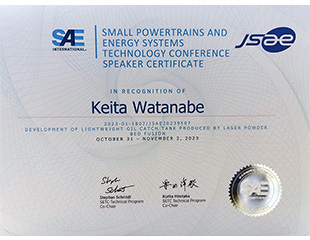

2023 SETC High Quality Paper Award

- Awarded

- Development of Lightweight Oil Catch Tank Produced by Laser Powder Bed Fusion

- Recipient(s)

- Keita Watanabe, Hirotaka Kurita, Shinya Iwasaki

Materials Division, Manufacturing Technology Center

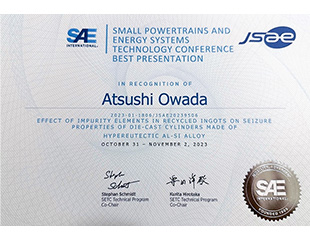

2023 SETC High Quality Presentation Award

- Awarded

- Effect of Impurity Elements in Recycled Ingots on Seizure Properties of Die-Cast Cylinders made of Hypereutectic Al-Si Alloy

- Recipient(s)

- Atsushi Owada, Takaharu Suzuki

Materials Division, Manufacturing Technology Center

2023 The Japan Institute of Light Metals (JILM) Light Metal Advancement Award

- Awarded

- Outstanding contributions to the body of academic research and technological development concerning light metals contributing to weight reduction with motorcycles, i.e., research into aluminum alloys; research for improving the durability of parts made of titanium alloys; R&D of vacuum die-casting technology, fatigue characteristics, bright heat treatment, coating technology, and more that led to the practical use of magnesium alloys for large parts like wheels and subframes; and other studies.

- Recipient(s)

- Takaharu Suzuki

Materials Division, Manufacturing Technology Center

2019 Japan Foundry Engineering Society Castings of the Year Award

- Awarded

- Lightweight, high-rigidity aluminum wheels

- These cast aluminum wheels for a sport Leaning Multi-Wheel (LMW)* model feature both light weight and high rigidity achieved through finite element analysis (FEA), which enables more realistic modeling, mid-cast solidification analysis to increase strength and resistance to pressure, and other engineering processes.

*Yamaha Motor’s designation for vehicles with three or more wheels that can lean through turns like a motorcycle. - Recipient(s)

- Kentaro Suenaga

Power Train Engineering Division, Production Engineering Section, Manufacturing and Production Engineering Center

2016 nano tech Initiative Award

- Awarded

- The Development of the Ceramics Nano-Film Coating Having Both High Corrosion Resistance and Excellent Heat Resistance

- Recipient(s)

- Naohisa Takahashi

Materials Division, Component Section, Engine Unit

2016 Oyamada Medal

- Awarded

- Development of world-leading weight-reducing parts and technologies for motorcycles

- Recipient(s)

- Toru Kitsunai

Material Division, Manufacturing Technology Section, Technology Center

Tsuyoshi Kubota

Materials Division, Component Section, Engine Unit

Takaharu Suzuki

Material Division, Research & Development Operations

2013 SETC High Quality Paper Award

- Awarded

- Application of Vacuum Assisted Carbide Dispersion Carbonitriding to Connecting Rods

- Recipient(s)

- Tsuyoshi Kubota

Materials Division, Component Section, Engine Unit

2012 SETC High Quality Paper Award

- Awarded

- Development of Lightweight DLC Coated Valve Lifter Made from Beta Titanium Alloy for Motorcycles

- Recipient(s)

- Hirotaka Kurita, Hirotaka Kurita

Component Section, Engine Unit

2006 JIM Technical Development Award

- Awarded

- Development of New Advanced Stainless Steel “NSSC21M” for Catalysis Substrate of Motorcycle Muffler

- Recipient(s)

- Naohisa Takahashi, et al.

Materials Division, Component Section, Engine Unit

2005 JDCA Urakami Award

- Awarded

- Development of an All-Aluminum Cylinder Using a Hypereutectic Al-Si Alloy

- Recipient(s)

- Hirotaka Kurita, Hiroshi Yamagata

Advanced Technology Research, Research & Development Operations

2005 Oyamada Medal

- Awarded

- Creation of various functions for motorcycle aluminum frames

- Recipient(s)

- Toru Kitsunai, Hiroshi Yamagata, Toshikatsu Koike

Research & Development Operations

2005 SETC High Quality Paper Award

- Awarded

- Effect of Elastic Deformation of the Honing Stone on the Exposure of Si-Crystals in a Hyper-Eutectic-Si Aluminum Cylinder Block

- Recipient(s)

- Hirotaka Kurita, Hiroshi Yamagata

Advanced Technology Research, Research & Development Operations

2005 JSTP Tokai Branch Technology Award

- Awarded

- Development of Fracture Splitting Method for Case Hardened Connecting Rods

- Recipient(s)

- Tsuyoshi Kubota, Shinya Iwasaki, Tsuneo Isobe, Toshikatsu Koike

Materials Division, Component Section, Engine Unit

2004 SETC 10 Best Paper Award

- Awarded

- Development of Fracture Splitting Method for Case Hardened Connecting Rods

- Recipient(s)

- Tsuyoshi Kubota, Shinya Iwasaki, Tsuneo Isobe, Toshikatsu Koike

Research & Development Operations

2003 SFJ Technology Award

- Awarded

- Hard Anodic Oxide Coating on the Piston-Ring Groove of a Cu-Rich Aluminum Piston with Mixed Acid Electrolytes

- Recipient(s)

- Hirotaka Kurita, Hiroshi Yamagata, Toshikatsu Koike, et al.

Advanced Technology Research, Research & Development Operations

2003 Oyamada Medal

- Awarded

- Development of cylinder liner in the new rapidly solidified aluminum alloy extruded material

- Recipient(s)

- Shuhei Adachi, Atsushi Inoue, Shigeru Okaniwa, Jun Kusui

Research & Development Operations

1998 Oyamada Medal

- Awarded

- Mass-production of high performance engine piston by forging technology

- Recipient(s)

- Toshikatsu Koike, Hiroshi Yamagata

Research & Development Operations

1998 JSPM Award for Innovative Development

- Awarded

- Development of SiC-Composite-PM Aluminum Alloy Piston

- Recipient(s)

- Toshikatsu Koike, Hiroshi Yamagata

Fundamental Technology Research, Technology Center

1987 Japan Lead Zinc Development Association Chairman’s Prize

- Awarded

- Practicalization of ZA-12 alloy

- Recipient(s)

- Yamada

1st Research Division