Casting Materials Guide

Here, we introduce some of the key characteristics of the main materials we use for casting parts.

ADC3

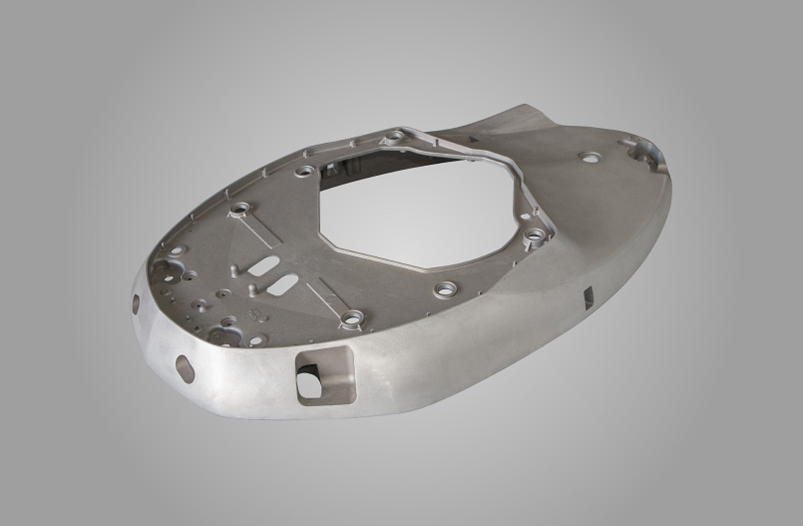

An Al-Si-Mg alloy for die-casting, it is well-suited to elongation and has excellent corrosion resistance, heat resistance, etc.

Parts using ADC3

ADC12

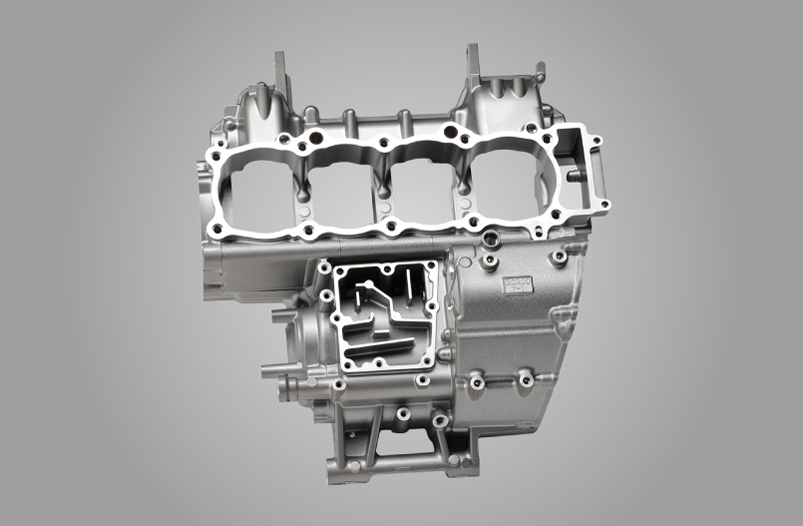

An Al-Si-Cu alloy for die-casting, it is the most commonly used material.

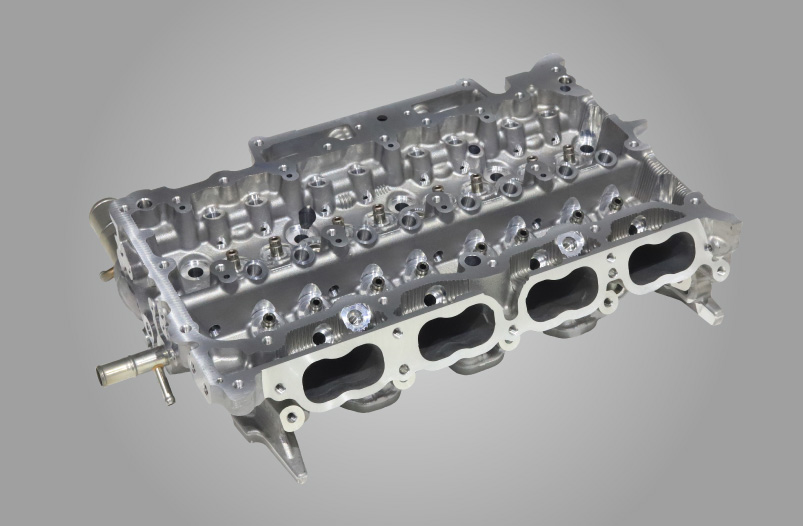

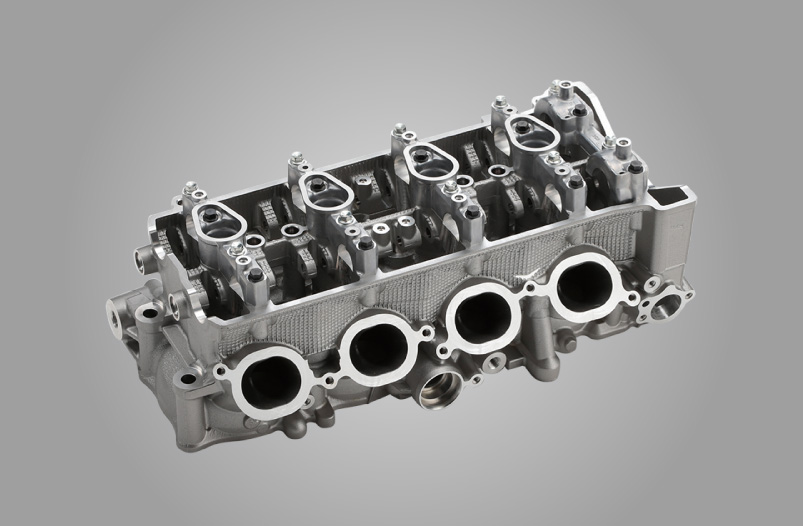

Parts using ADC12

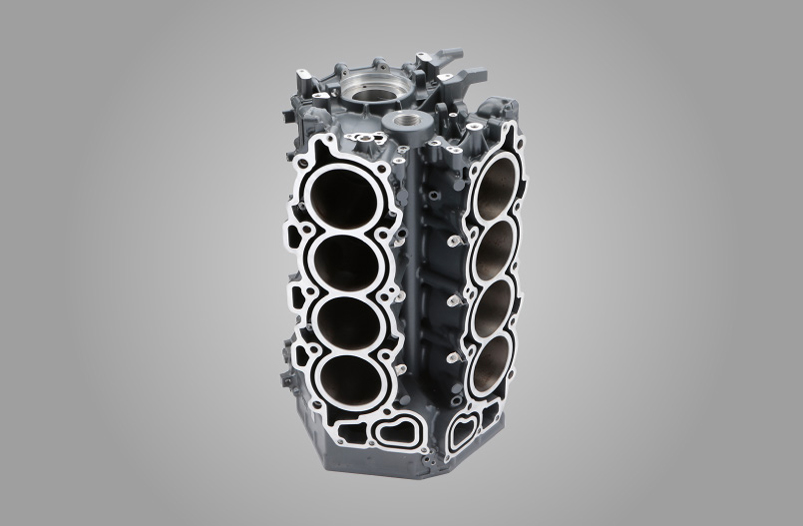

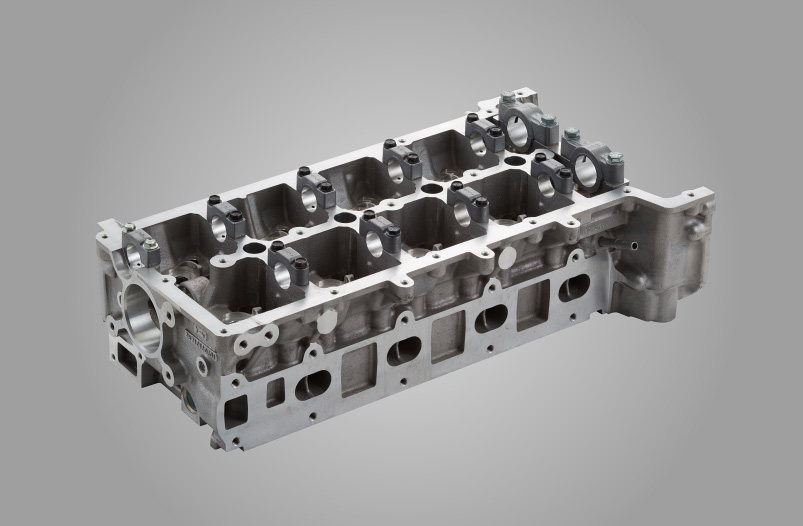

AC2B

An Al-Cu-Si alloy for mold casting, it is the most commonly used material.

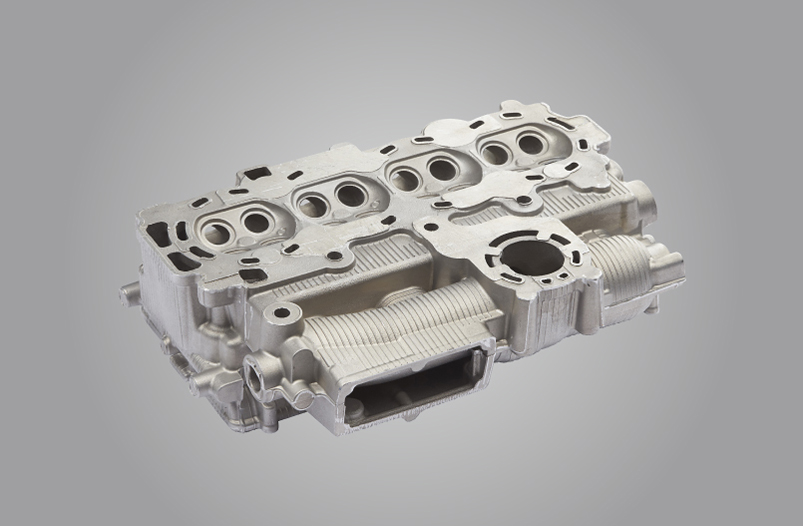

Parts using AC2B

AC4B

An Al-Si-Cu alloy for mold casting, it is the most commonly used material.

Parts using AC4B

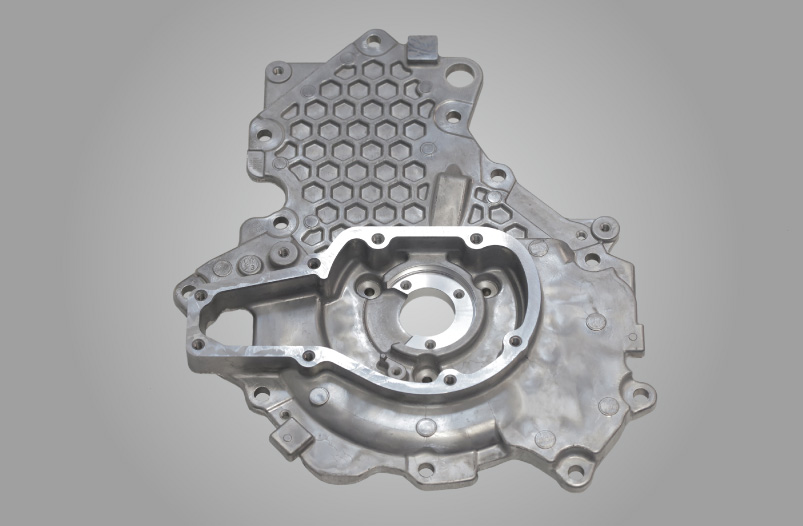

AC4C

An Al-Si-Mg alloy for mold casting, it is well-suited to elongation and has excellent corrosion resistance, heat resistance, etc.

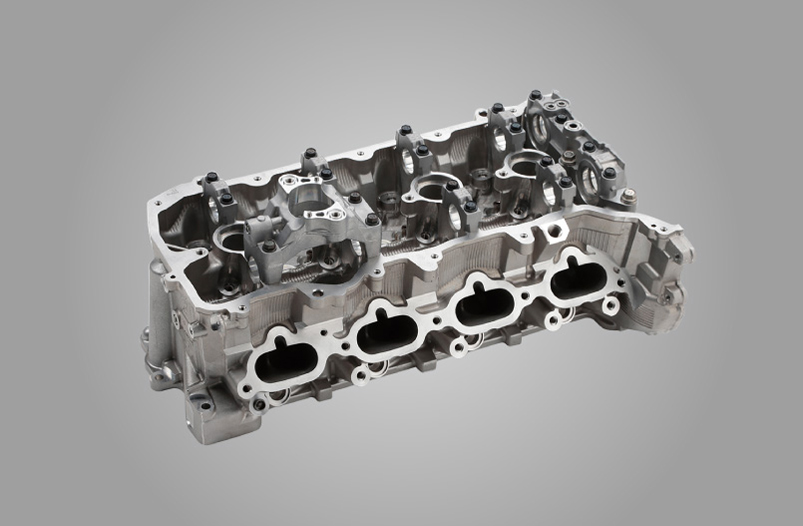

Parts using AC4C

AC4CH

An Al-Si-Mg alloy for mold casting, it has standout elongation qualities, but also excellent corrosion and heat resistance.

Parts using AC4CH

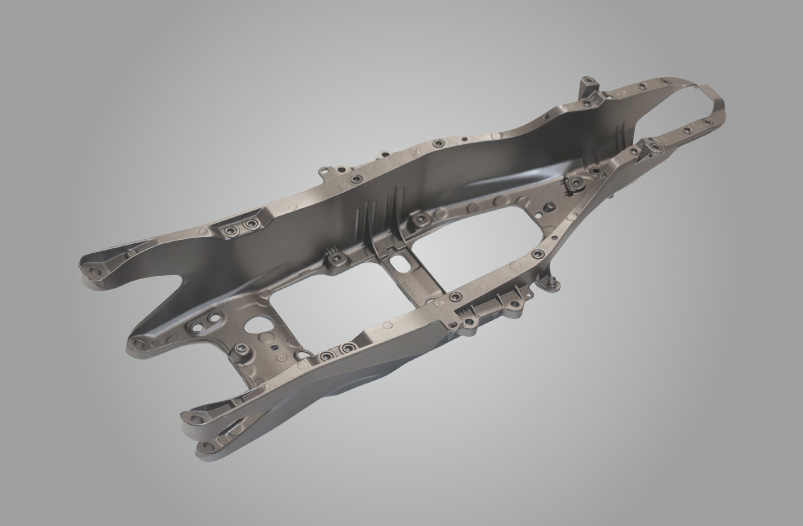

MD2B(AM60)

An alloy for magnesium casting, it is well-suited to elongation and has excellent strength, etc.

Parts using MD2B(AM60)

MD1D(AZ91)

An alloy for magnesium casting, it is the most commonly used material.

Parts using MD1D(AZ91)

Useful Information

Due to current circumstances, we have temporarily stopped accepting enquiries.

We apologize for any inconvenience caused and we are hoping for your kind consideration.

We apologize for any inconvenience caused and we are hoping for your kind consideration.