Our Facilities – Iwata South Factory (Bldg. M2)

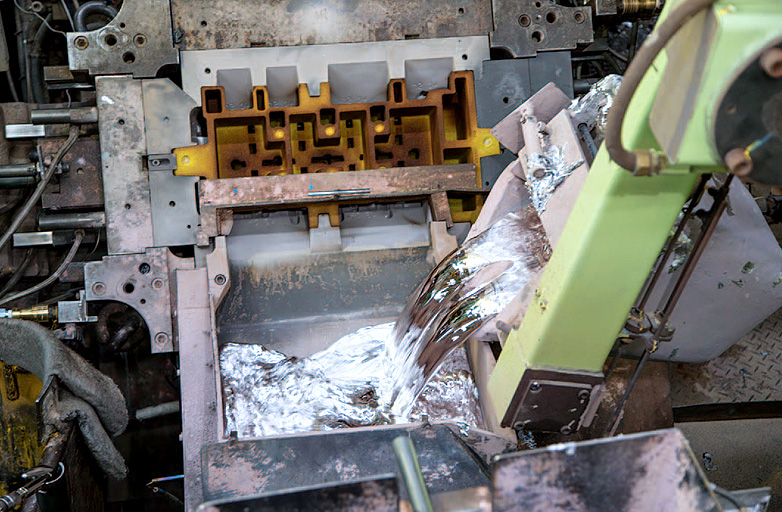

We have well-maintained and dependable facilities with a proven track record for creating high-quality parts. We also have a full array of machinery and the versatility to perform a wide variety of manufacturing methods.

| Material | Machinery | # | Details |

|---|---|---|---|

| Aluminum | Melting furnaces | 1 | Tower type: 1.5 tons/hour × 1 |

| Degassing equipment | 1 | FF Shizunami × 1 | |

| Low-pressure casting machines | 7 | Small (500 kg holding furnace) × 3 / Large (1,000 kg holding furnace) × 4 | |

| Knockout machines | 4 | General-purpose | |

| Heat treatment furnaces | 14 | Continuous type using baskets × 2 / batch type × 12 | |

| Milling machines | 8 | Multipurpose NC milling | |

| AGV | 1 | Automatic transport of pallet steel cages | |

| Die-casting machines | 5 | 3,500-ton × 1 / 2,500-ton × 3 / 1,650-ton × 1 | |

| Melting and holding furnaces | 5 | Directly linked to the die-casting machines (including degassers) | |

| Impregnation system | 1 | – | |

| Surface finishing machine | 2 | Shotblast | |

| Automatic deburring machines | 4 | 2 sets × 2 | |

| CT scanner | 1 | Industrial CT scans for verifying part dimensions | |

| Coordinate measuring machines | 2 | Articulated type × 1 / shop floor type × 1 | |

| Chemical composition analyzer | 1 | Optical emission spectrometer |

* as of April 2022

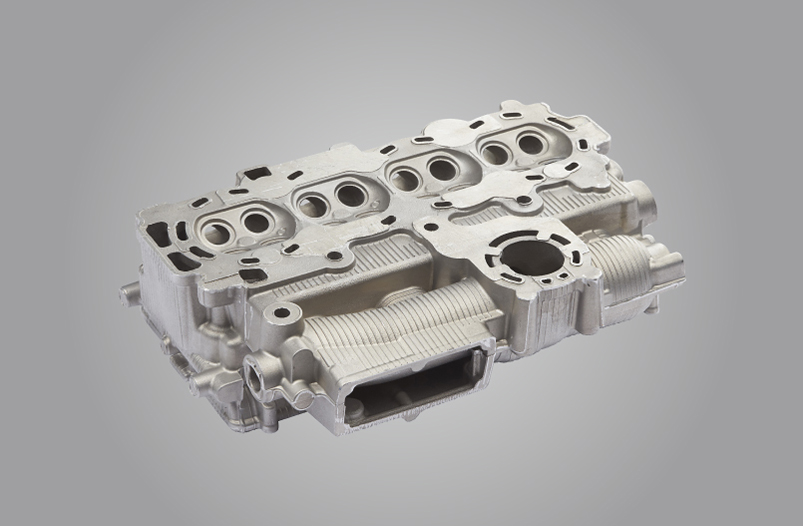

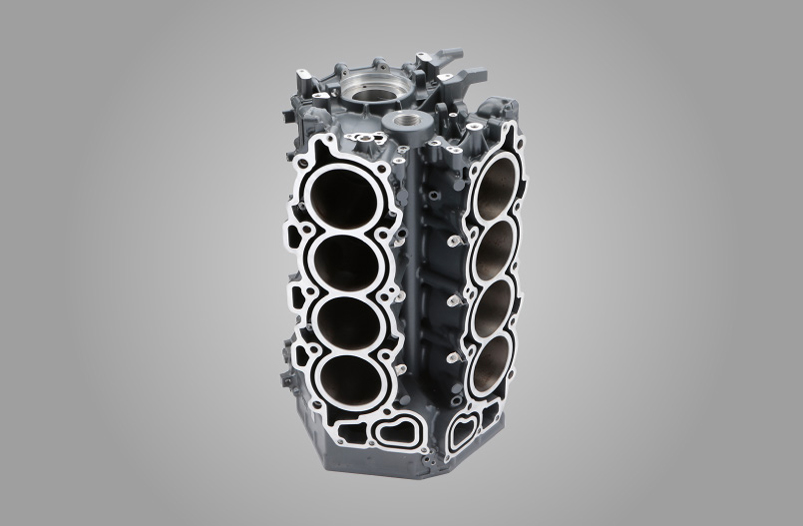

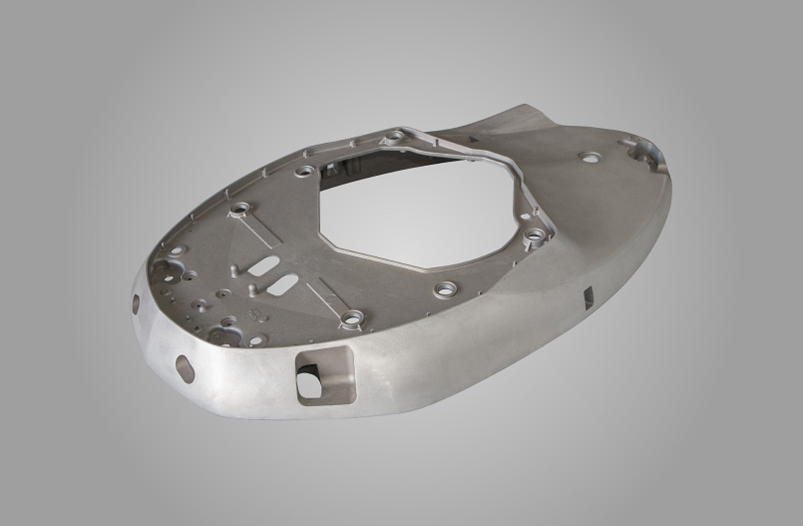

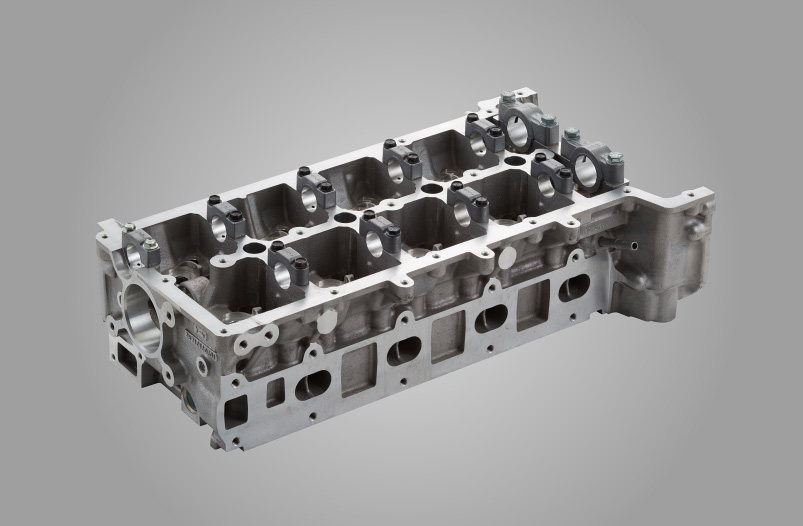

Related Products

Due to current circumstances, we have temporarily stopped accepting enquiries.

We apologize for any inconvenience caused and we are hoping for your kind consideration.

We apologize for any inconvenience caused and we are hoping for your kind consideration.