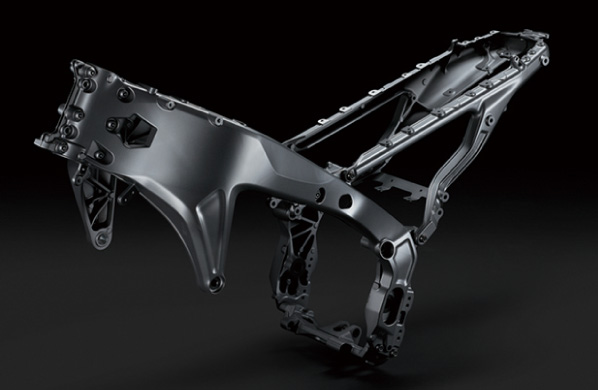

Inexpensive, Lightweight Motorcycle Aluminum Frames with High Design Appeal

Aluminum frames made with our CF die-casting technology

Our CF (controlled filling) die-casting technology yields a number of benefits, such as higher vacuum degree in the mold cavity, precise control of mold temperature, and higher melt injection (flow) speed. We also developed a special release agent to facilitate separation of the finished casting, and all of these led to a significant reduction in gas porosity defects in the cast aluminum piece. Further, CF die casting enables us to create lighter, more rigid castings with high design appeal while also reducing manufacturing costs. In comparison, the frame of a previous motorcycle model made of steel pipe was composed of 88 individual parts, required 9 m of welding, and weighed 22.5 kg. The latest CF die-cast frame consists of only 7 parts, requires no welding at all, and weighs only 13.8 kg.

Need

- Aluminum motorcycle frames with greater engineering and design freedom that are high in performance but low in cost

DevelopmentDirection #1

- Reduce the number of parts to raise manufacturing efficiency and lower costs

DevelopmentDirection #2

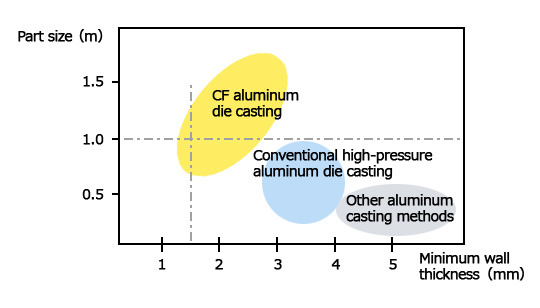

- Achieve high dimensional precision even with large parts with thin sections

DevelopmentDirection #3

- Achieve lower weight and higher rigidity while providing greater freedom for engineering and design

Solution

01CF Aluminum Die-Casting Technology

Yielded higher vacuum degree in the mold cavity, precise control of mold temperature, and higher melt injection (flow) speed. Also developed a special release agent

02Die Casting Material Development

Developed aluminum alloys and other base materials for die casting for greater toughness, strength, etc.

03Die-Casting Technologies

Reduced the volume of gas porosities and enabled welding of cast pieces to each other

Using ADC3 (Silafont36) for high strength and toughness

Result

| 2003 model | 2004 model | 2020 model | |

|---|---|---|---|

| Frame construction | Steel pipe + welding | CF die casting Steel pipe + welding | CF die casting |

| Number of parts | 88 | 31 | 7 |

| Length of welds | 9m | 2.9m | 0m |

| Frame weight | 22.5kg | 16.8kg | 13.8kg |

We apologize for any inconvenience caused and we are hoping for your kind consideration.