Our Facilities – Hamakita Factory

We have well-maintained and dependable facilities with a proven track record for creating high-quality parts. We also have a full array of machinery and the versatility to perform a wide variety of manufacturing methods.

| Machinery | # | Details | |

|---|---|---|---|

| Hot forging | Gear forging line #1 | 2 | 300 kW induction furnace × 2 / 500-ton screw press × 2 / continuous normalizing furnace × 2 |

| Gear forging line #2 | 1 | 150 kW induction furnace × 1 / 1,000-ton 3-station crank press × 1 / continuous normalizing furnace × 1 | |

| Gear forging line #3 | 1 | 300 kW induction furnace × 1 / 1,600-ton 3-station crank press × 1 | |

| Crankshaft forging line #1 | 1 | 150 kW electric upsetter × 4 / 800-ton screw press × 1 | |

| Hot forging general production line #1 | 1 | 550 kW induction furnace × 1 / 1,600-ton 4-station crank press × 1 | |

| Cold forging | Forging machines | 11 | Knuckle press: 600-ton × 1 Crank press: 150-ton × 1 / 250-ton × 1 Link press: 630-ton × 3 Hydraulic press: 200-ton × 1 / 315-ton ×1 / 400-ton × 1 / 400-ton 3-station × 1 / 600-ton 2-station × 1 |

| Lubrication treatment machine | 1 | Automatic bonderizer × 1 | |

| Heat treatment | Heat treatment furnaces | 4 | Mesh belt continuous annealing furnace × 1 / continuous normalizing furnace × 3 |

| Surface finishing machines | 3 | Shotblast | |

| Inspection/measurement equipment | 1 | Magnetic particle inspection machines | |

| 1 | Shape scanner | ||

| 1 | Image dimension measuring device | ||

* as of April 2022

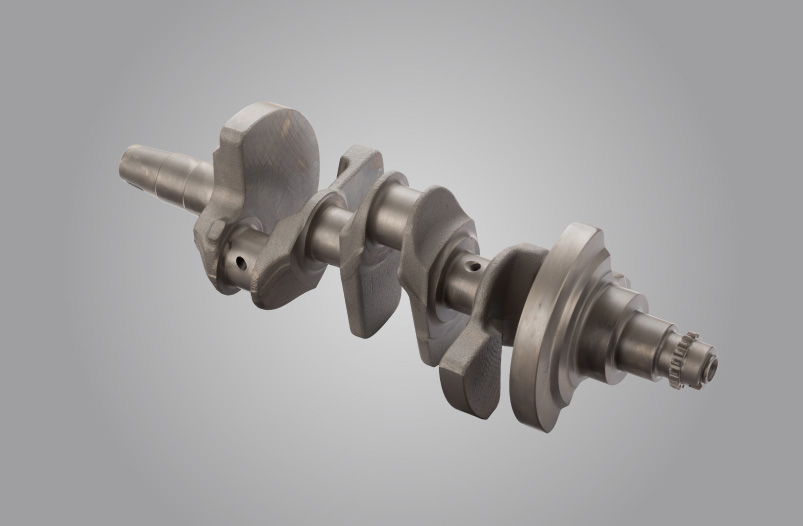

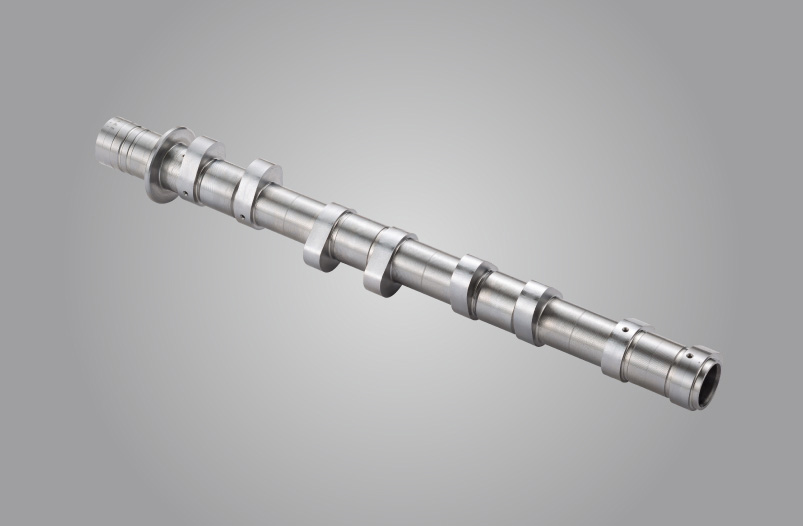

Related Products

Due to current circumstances, we have temporarily stopped accepting enquiries.

We apologize for any inconvenience caused and we are hoping for your kind consideration.

We apologize for any inconvenience caused and we are hoping for your kind consideration.