Forging/Heat Treatment

Forged parts help reduce weight and boost performance, and our precision forging technologies allow us to create parts with complex shapes requiring the highest levels of skill.

Our quality is our pride and we put our hearts and souls into crafting every forged and heat-treated part for motorcycles.

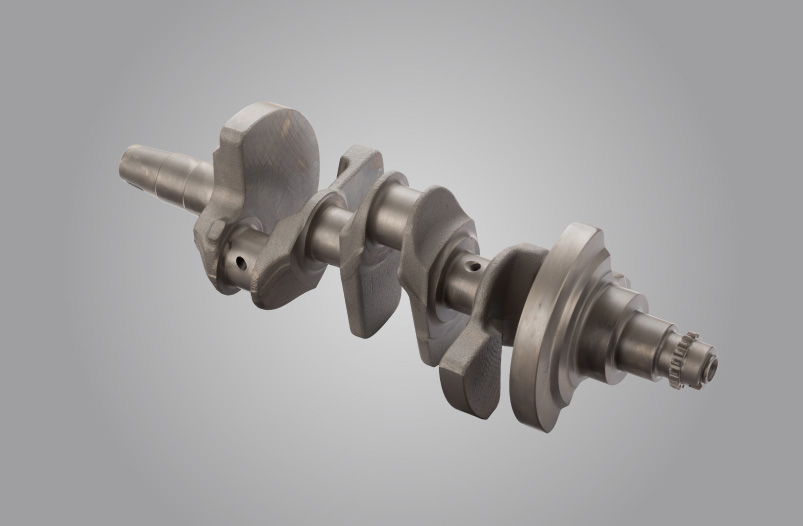

- Crankshaft

- Transforming the reciprocating motion of the pistons into rotational motion, the crankshaft is a vital part of the engine. Yamaha crankshafts offer high performance at low cost.

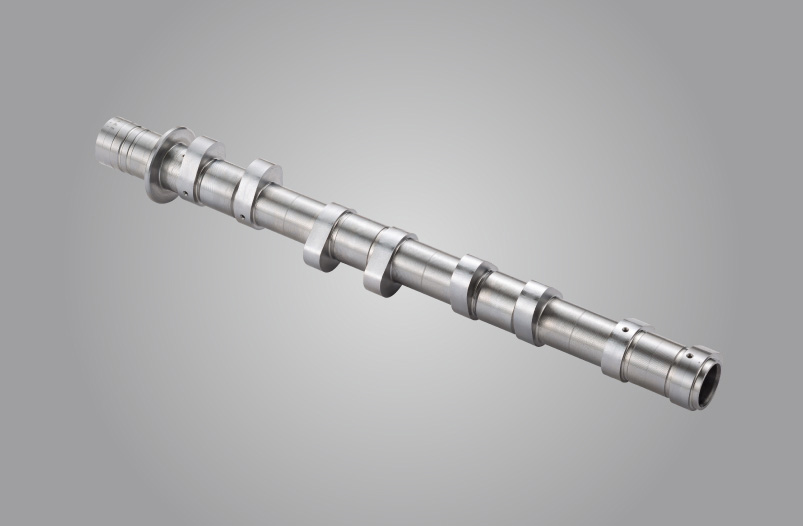

- Camshaft

- Camshafts play an important role in determining an engine's power characteristics. Carburizing followed by quenching and tempering ensures a high degree of hardness.

- Transmission Gear

- Even with their complex shapes, transmission gears can be forged with a high degree of precision using a combination of hot and cold forming.

- Driveshaft

- Produced using an automated transport system for the many work processes involved, our driveshafts are not only strong and low-cost, but also contribute to higher engine performance.

- Assembled Crankshaft

- Our high-efficiency manufacturing techniques significantly reduce production costs and result in tough, durable crankshaft parts.

- Forged Aluminum Piston (Alumite-treated)

- Though difficult to manufacture, Yamaha has mastered forging large-diameter aluminum pistons with high levels of precision.

- Forged Aluminum Piston (Defric-coated)

- These forged pistons have complex shapes and are used in high-performance engines.

- Forged Aluminum Piston (Tin-plated)

- Applying tin plating to forged pistons improves their break-in characteristics.

Due to current circumstances, we have temporarily stopped accepting enquiries.

We apologize for any inconvenience caused and we are hoping for your kind consideration.

We apologize for any inconvenience caused and we are hoping for your kind consideration.