【Discontinued Product】3D-Xray Hybrid Inspection System YSi-X Overview

Complete renewal and updating of both hardware and image processing software has vastly improved x-ray 3D imaging and led to the advanced TypeHD/TypeHB.

- Ideal for 100% inspection of onboard automotive products and many other items by 3D X-rays Acquire Layered of Target

- Switchable Tube voltage 130KV (onboard vehicle use), 110KV (household use), 70KV (device use)

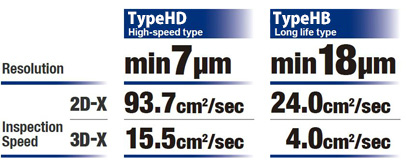

- Select the type you need X-ray detector, TypeHD (Wide-angle High-speed type), or TypeHB (Long service life type)

- X-ray, optical, infrared, and laser height measurement as standard equipment. Hybrid and High Reliability with Multiple Inspection Modes

Function and Feature

Inspection with 3D X-rays Slice Section Image

PCB warping is corrected with XYZ fiducial function

Equipped with 3D X-ray, 2D X-ray, Visible, Laser and Infrared

Data Link with Mounter

Recommend for Such Production Site

For customers who want to inspect each and every inspection point on a single unit

Capable of inspecting the desired point with the desired head. X-ray hybrid inspection device.

Hybrid inspection device utilizing 2D optical, 3D, 3D x-ray, and laser.

- 2D inspection function: Extracts images and makes inspection settings automatically using 3 optical inspection algorithms for brightness, color and shape.

- 2D optical inspection function: Realizes high repeatability by way of a high rigidity frame equivalent to a mounter and 5 million pixel camera, etc. Resolution of 10μm or 19μm is selectable.

- Swivel type laser measurement: Measures the PCB's height setting. It is also capable of automatic inspections.

- 3D X-ray CT inspections: It can check solder connections via slice plane images. Resolution: TypeHD: mini7μm/TypeHB:mini18μm.

3D X-ray inspections: Selectable from 2 types

- "3D-X TypeHD(High-speed high-accuracy):FOS flat panel method X-ray detector estimated service life: 1 year Speed : 5.8cm2/second"

- "3D-X TypeHB (long-life): Direct conversion panel method X-ray detector estimated service life: 4 years Speed : 1.4cm2/second"

- Utilizes Yamaha unique in-house digital X-Ray CT imaging technology. It can verify solder connections via slice plane images and can also extract and inspect X-ray slice images at any desired height.

Makes high accuracy judgments on a repair viewer

- At the repair station, 3D X-Ray inspection results are directly checked as 3 dimensional images and a final judgement made.

Equipped with convenient functions that support data creation and judgements.

- Yamaha standard library: Yamaha’s in-house developed standard inspection library linking to approximately 80,000 types of SMT components Just choose a component shape and paste it to complete the inspection data.

- Supports making visual judgements at the repair station and making image judgements from a remote station.

- P-tool AOI limited (Ysi-OS iPRODB): Create data and use statistic analysis software on an offline PC. It also makes judgement rankings, all image saving and search, monitoring and trace.

Promotion Movie

Related contents

- Product

- Introduce our product lineup, including surface mounters, solder printers, and visual inspection machines.

- Showroom

- Find and explore SMT Smart Showroom or Virtual Showroom

- Intelligent Factory

- IoT/M2M Integration system - System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.