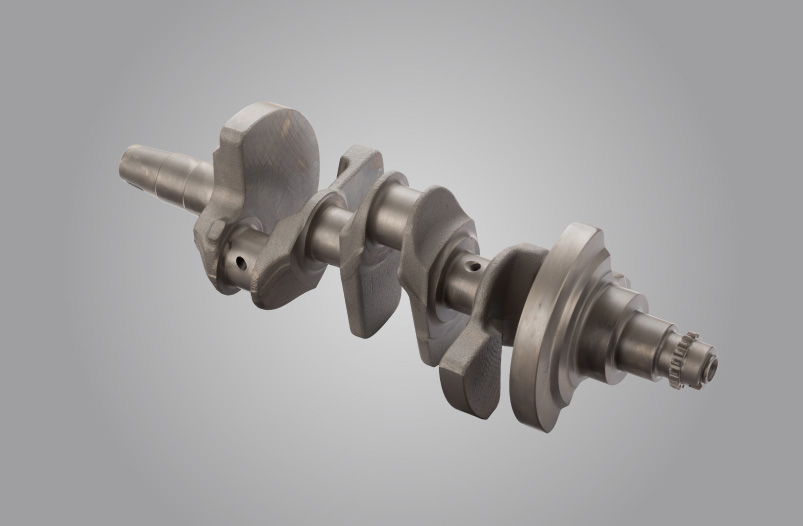

Assembled Crankshaft

Our high-efficiency manufacturing techniques significantly reduce production costs and result in tough, durable crankshaft parts.

Assembled Crankshaft

Forging

A single hot forging machine performs all the work processes—including cutting, de-burring and drilling—to produce a complete forged crankshaft piece. Also, Yamaha has developed a die cooling process to shorten cycle time, reduce the amount of release agent used and more, all leading to lower costs.

Heat Treatment

Carburizing and quenching is used to increase surface hardness, and improve bending fatigue strength, surface fatigue strength and wear resistance. This makes for high-performing, longer-lasting products.

| Product category | Motorcycles/Outboard Motors |

|---|---|

| Forging method/ heat treatment |

Hot forging, carburizing and quenching, thermal refining + induction hardening |

| Material | S45C or equivalent |

| Used for | Engines |

We apologize for any inconvenience caused and we are hoping for your kind consideration.