YZR-M1 Technical Guide

Introducing the 2010 YZR-M1.

YZR-M1 Technical Guide | Evolution of the YZR-M1, powering Yamaha to a 3rd straight Triple Crown

In 2010, Yamaha became the first maker in the history of the MotoGP to win three consecutive triple crowns of rider, manufacturer and team titles. This momentous achievement obviously could not have been possible without the ongoing evolution of the YZR-M1 machine. Here, we hear about the progress made in the M1's development in the words of none other than the MotoGP Group Manager of Yamaha Motor's Motor Sports Development Division, Masahiko Nakajima.

"Man-Machine Collaboration" realized through sound,

substantial machine evolution

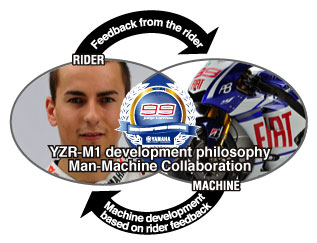

Our prime objective in developing the YZR-M1 in 2010 was to achieve the kind of "Man-Machine Collaboration" that could bring out the rider's abilities to the fullest. The process involved utilizing information gathered from the rider's feedback to develop the machine with the aim achieving a user-friendliness that would allow the rider to put complete trust in it and thus be able to concentrate fully on racing to win. In that sense, it can be said that the 2010 YZR-M1 was not merely an inorganic mechanical device but an embodiment of Yamaha's Human Technology, an engineering ideal that seeks to bring out higher levels of comfort, enjoyment and performance through rider-machine communication. The fact that the M1 won 11 of the 18 rounds in the 2010 and brought Yamaha its third consecutive MotoGP triple crown is certainly proof that this engineering and development approach was not wrong.

The 2010 machine development policy

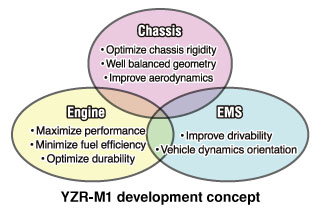

As in years past, development of the 2010 machine's specs proceeded in the three areas of chassis, engine and the EMS (Engine Management System). The development policy for the year was to continue pursuing the directions of the previous year in a straightforward, incremental type of development process that we commonly call machine maturation. It did not involve any attempts at revolutionary advances by adopting completely new technologies for a drastic change in development direction. In order to accommodate the new regulation that limited the number of engines that could be used in a season to six, efforts also focused on improving the durability of the engines and maximizing tire performance.

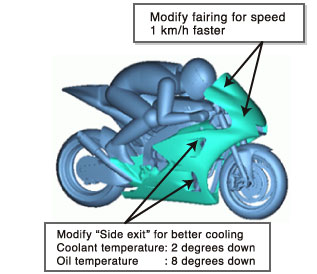

Chassis development

Development of the chassis focused on making further advances in optimizing chassis rigidity, achieving well-balanced geometry and improving aerodynamics. In particular, changes were made in the chassis rigidity to increase handling stability and improve tire grip. This involved lessening rigidity in the lateral direction while maintaining current levels of longitudinal rigidity and rigidity with regard to torsion (twisting). In the area of aerodynamics, the shape of the cowling (fairing) was reviewed and changes made to achieve higher top speed. Furthermore, a "side exit" was added to the side cowling to improve airflow dynamics and also achieve greater cooling effect to lower engine coolant temperature (-2°C) and oil temperature (-8°C).

Engine development

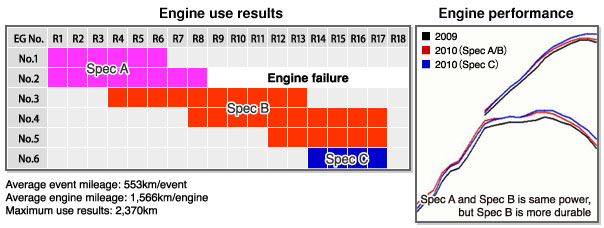

To achieve optimum performance within the regulation limiting the number of engine to be used in a season, three different specs were introduced in succession.

- Spec A introduced early in the season featured improved durability and mid-speed performance.

- Spec B introduced mid-season had further improvements in durability compared to Spec A.

- Spec C introduced later in the season maintained durability while boosting drive dynamics.

The target for engine endurance was 2,000 km per engine. The distance run in each round averaged about 550 km, and considering that at least two engines were used in each round (event), it meant that each engine could be used over a span of about ten rounds. While there was some difference in the actual distance run with each engine spec, the third and fourth specs were in fact used over a span of ten rounds. For purpose of reference, the average distance run on the six engines was 1,566 km.

EMS development

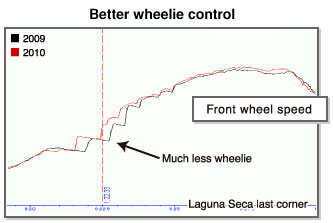

In the EMS development, advances were made in adaptability to different race/track conditions. In the area of stability in running performance, a level was reached where there was almost no difference in tire slip ratio between the early and latter laps of the races, which contributed greatly to handling performance for the rider. There was also a big improvement in wheelie control compared to last year.

2010 season achievements and results

From the first years until the present, development of the YZR-M1 has always been done hand-in-hand with the riders. The process of communication with the riders has brought the highest levels of machine function. As we said at the start of this report, the winning of a third consecutive MotoGP triple crown in 2010 proved that this approach was not wrong. Its effectiveness has also been proved by the winning of five championship titles in the seven years since 2004. Next season Yamaha will continue to develop this philosophy of Man-Machine Collaboration as our development direction.