Initiatives for "Climate Change"

Yamaha Motor works on solution to issue of climate change through its business activities.

Contents

- Reduction of CO2 Emissions from Products

- Improve the fuel efficiency of ICE systems

- Expand the mobility service business in India

- Upgrade and expand BEV products

- Field Tests for Expanding Sales of BEV Models Working to Create a Carbon-Neutral Age

- Providing a Sharing Service for Common Specification Batteries for Electric Motorcycles

- Develop power trains with carbon neutral fuel capabilities

- Reduce CO2 Emissions from Business Locations

- Theoretical Value Energy Activities: Global Implementation

- Pursuit of Valuable Energy

- Theoretical Value Energy Activities: Smart Factories Based on Theoretical-Value-Based Production

- Expand Use of Renewable Energy: Setting Targets for the Ratio of Renewable Energy

- Expand Use of Renewable Energy at Production Sites: Introducing CO2 - Free Electricity

- Update Facilities, Reform Processes: Installing Energy-Saving Equipment

- Switch from Fossil Fuels to Electricity: Moving Away from Fossil Energy

- Reduction of CO2 Emissions in Distribution

Reduction of CO2 Emissions from Products

For over 60 years since its founding, Yamaha Motor has used the lightweight, compact, durable and reliable concepts of its Monozukuri (engineering, manufacturing and marketing) as a strength to constantly offer new value and carve out new markets. At sea, on land, in the air. For leisure, for industry, for lifestyles. We provide a diverse range of distinctive products in over 180 countries and territories.

80% of the CO2 emissions from Yamaha Motor Group come from CO2 emissions associated with the use of our products (Scope 3. Category 11.) . To tackle the issue, we have set up the following four strategic policies to help achieve carbon neutrality when our products are used.

- Improve the fuel efficiency of ICE systems

- Upgrade and expand BEV products

- Expand sales of BEV models

- Develop power trains with carbon neutral fuel capabilities

Improve the fuel efficiency of ICE systems

50% of the CO2 emitted when our company's product lines are used (Scope 3. Category 11) originates from the whole Asian region, with 87% of emissions coming from two-wheeled vehicles.

In emerging nations, two-wheelers are a cheap and convenient means of transportation for delivery, two-wheeled taxis and commuting to work or school. They also serve an important role as part of the social infrastructure that supports the movement of persons, goods and services.

While closely following Nationally Determined Contribution (NDC) targets for greenhouse gas reduction as well as energy policies and regulatory movements in various countries and territories, Yamaha Motor will further improve the fuel consumption of ICE systems as a cheap, convenient and highly mobile option and also popularize models equipped with the low-carbon BLUE CORE engine. In this way, we will encourage the economic growth of emerging nations from the standpoint of the SDGs while creating jobs and providing solutions to environmental issues.

BLUE CORE: A motorcycle engine design concept that balances riding performance, fuel economy and environmental performance at a high level

Expand the mobility service business in India

Yamaha Motor Co., Ltd. has established a new company "Moto Business Service India Pvt. Ltd. (MBSI)" in India for the purpose of expanding the mobility service business. The Company has also begun leasing motorcycles to Royal Brothers, a local mobility service provider that offers motorcycle rentals and other services.

MBSI will run an asset management business by leasing motorcycles to Mobility as a Service (MaaS) operators providing services for vehicle sharing, taxis, logistics, and more. By creating job opportunities through our business, the company will contribute to improving the quality of life for people in India. In addition to Royal Brothers, MBSI will aim to expand Yamaha Motor’s mobility service business in India through collaborations with other MaaS operators going forward.

Upgrade and expand BEV products

Since the 1980s, we have marked electric power as a potential solution to environmental and energy resource problems, and we have pursued technological research to that end. In 2002, we launched the Passol, the first mass-produced electric scooter. Since then, while keeping the ideal EVs for each region in mind, we have sought to expand the possibilities of mobility and create better lifestyles and societies through the electrification of a diverse range of products including not only two-wheeled vehicles but also electric golf cars, compact low-speed cars (land cars), electrically power assisted bicycles, electric wheelchairs and drones.

Electrically Power Assisted Bicycles

Electric Wheelchairs

Electric Scooter

Electric golf car

Electric Propulsion Unit

Industrial Multi-rotor

Field Tests for Expanding Sales of BEV Models Working to Create a Carbon-Neutral Age

Expanding the sales of BEV products will require social infrastructure such as charging stations.

We will introduce the E01* to business offices, local governments and public agencies as a field test to help us understand customer needs, pursue possibilities in peripheral businesses and develop new markets in order to build EV infrastructure and the sharing business.

The E01 is equipped with a CCU (Communication Control Unit).

The information communicated is integrated with information from the VCU (Vehicle Control Unit) and periodically uploaded to our web servers as vehicle information (location information, riding status).

Information such as riding logs, battery level and last location parked can be accessed via a web app.

From this data, we can estimate the future needs of motorcycle EV-using organizations and riders, which we will use as reference when developing products or advocating for infrastructure that meets social needs.

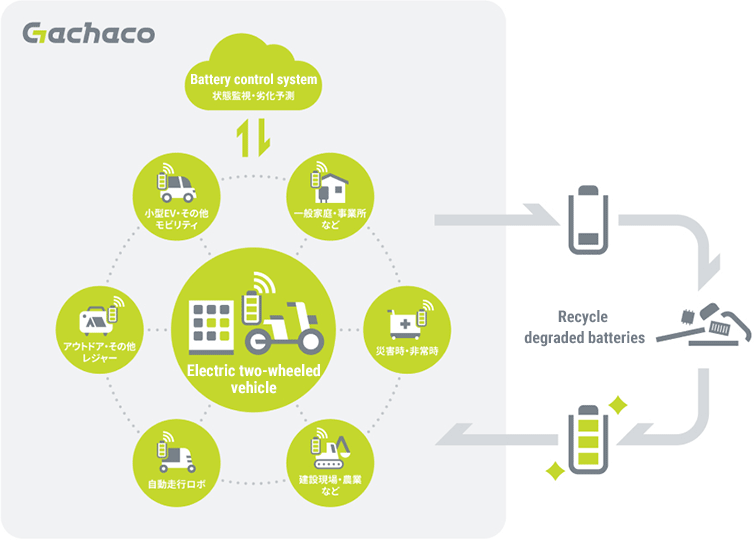

Providing a Sharing Service for Common Specification Batteries for Electric Motorcycles

On April 1, 2022, five companies, namely ENEOS Holdings, Inc., Honda Motor Co., Ltd., Kawasaki Motors, Ltd., Suzuki Motor Corporation and Yamaha Motor Co., Ltd., established Gachaco (Gachaco, Inc) to provide sharing services for common specification batteries for electric motorcycles and develop infrastructure for sharing services. Gachaco aims to build a battery charging network as infrastructure so that all who use electric mobility vehicles can ride safely and securely without worrying about running out of battery charges. The network will also help create a carbon-free, recycling-oriented society.

Research and development into powertrain technologies that help to realize carbon neutrality.

As part of our efforts to achieve carbon neutrality, Yamaha Motor is researching and developing powertrain technologies that are compatible with electric motors and with a variety of energy sources such as biofuels, efuels, and other carbon neutral fuels.

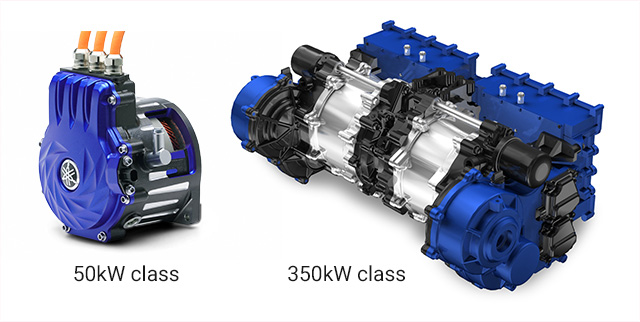

Development of electric motors

The electric motor (maximum output 50kW class) developed for compact mobility products featured a segment conductor in its coil, and increasing the space factor allowed the creation of a high-output, highly efficient and lightweight (the unit weight of the 50kW class is 13kg) unit.

It also has excellent cooling performance thanks to the adoption of the casting technology and heat management technology cultivated through the development of internal combustion engines.

The 350kW class units developed to be installed in high-output mobility products have a compact "mechatronic system integration" structure where the gears and inverter are one, and it can be used at a maximum voltage of 800V. If four of this unit are mounted on a single vehicle, a maximum output of 1.47MW (2,000 horsepower) is possible.

Hydrogen engine development

In pursuit of carbon neutrality, Kawasaki Heavy Industries, Ltd., Subaru Corporation, Toyota Motor Corporation, Mazda Motor Corporation and Yamaha Motor Co., Ltd. have begun to discuss the possibility of joint research into expanding the options for fuels used in internal combustion systems.

Yamaha Motor is developing hydrogen engine technology that could potentially be installed in the company's products such as motorcycles and ROVs (four-wheeled buggies).

αlive RX high-performance range extender unit

Designed with the anticipation that it would be used in compact, lightweight and powerful applications such as in drones, αlive RX is a compact unit that delivers high performance with an estimated 88kW in maximum output.

Replacing some of the batteries in an electric mobility vehicle with this unit can substantially extend the vehicle’s cruising range and operating time.

It is also compatible with next-generation fuels.

αlive H2E (hydrogen engine)

The αlive H2E is an internal combustion engine that employs existing engine technologies to burn hydrogen and use the energy produced, without emitting CO2.*1

Outside of use in mobility powertrains, hydrogen engines hold great potential for use with machines like generators, making such technology a potential pathway to more means of achieving carbon neutrality.

*1 Does not include the ultratrace amounts of engine oil burned during combustion.

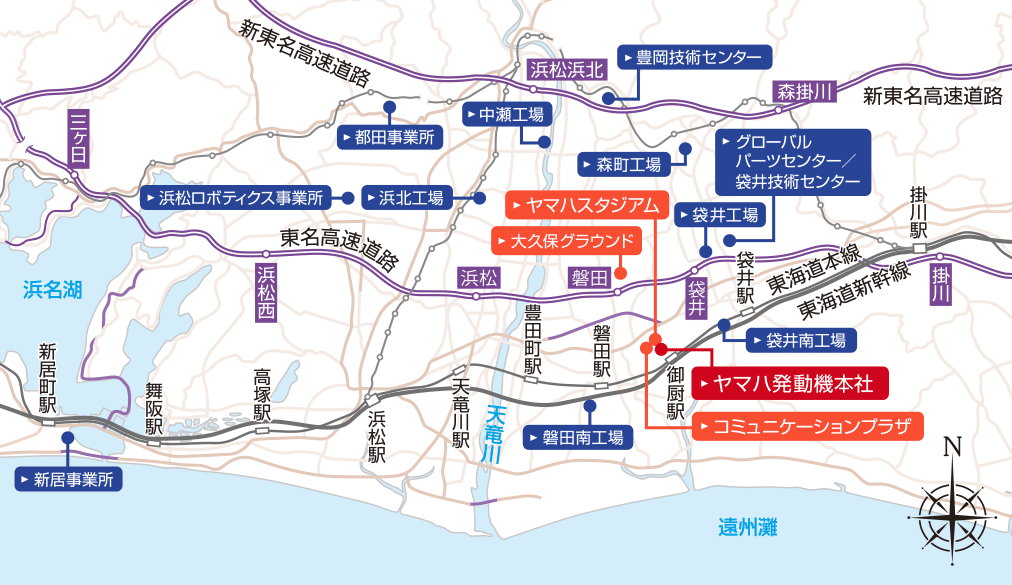

Reduce CO2 Emissions from Business Locations

The Yamaha Motor Group has 140 business locations in 30 countries around the world. Among them are 27 manufacturing factories in 16 countries under the jurisdiction of the Manufacturing and Production Engineering Center. Many of them handle everything from casting and processing steel and aluminum to stamping, welding, forging, heat treating, resin molding, painting and assembly in-house.

To reduce CO2 emissions from our business locations, we analyzed the whole Group by process type, region and energy type used and drew up the following four strategic policies.

Four Strategic Policies

- Theoretical value energy activities

- Expand use of renewable energy at production sites

- Update facilities, reform processes

- Switch from fossil fuels to electricity

Theoretical Value Energy Activities: Global Implementation

At Yamaha Motor, we are working to reduce CO2 emissions of the entire Group by cooperating with overseas Group companies and sharing energy-saving know-how accumulated within Japan. Specifically, we are implementing a "theoretical value energy" approach, in which we define the value and quasi-value of each facility and process at our production bases in Japan and abroad, identify the essential functions, and aim to minimize loss. To date, we have visited 30 locations in 13 countries, covering 98% of Groupwide CO2 emissions, in our effort to reduce energy loss.

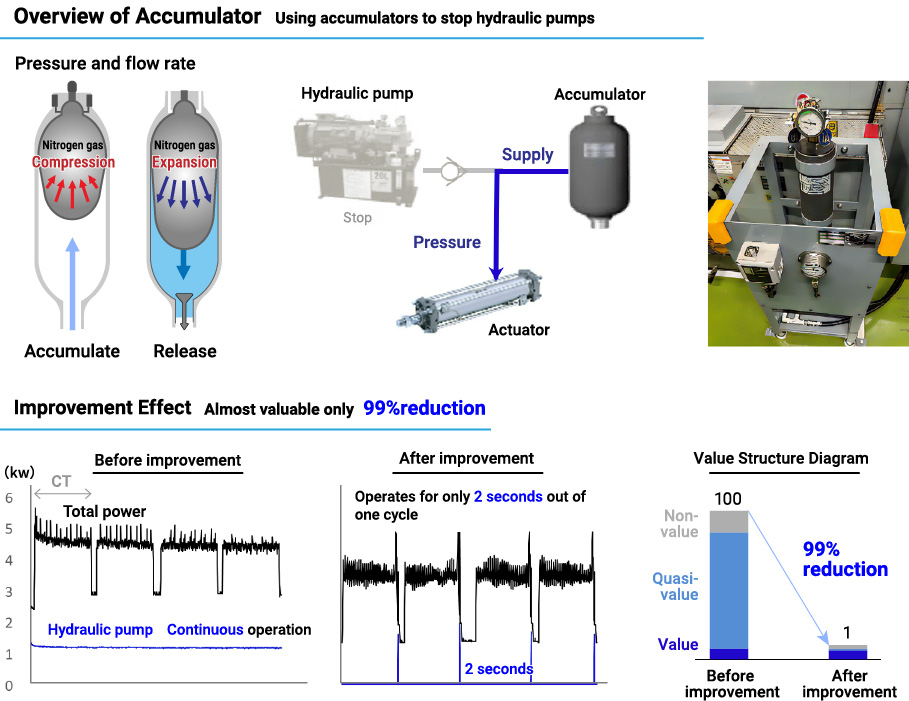

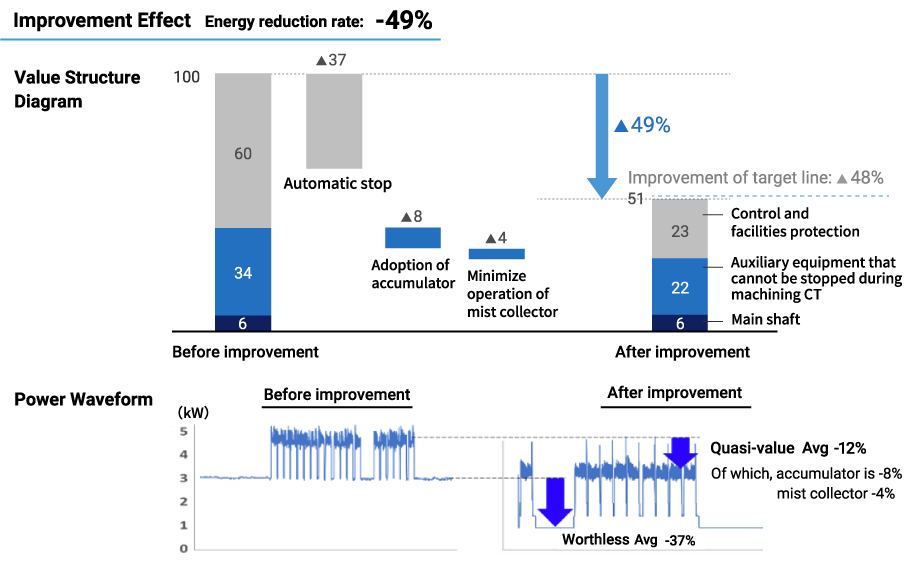

Theoretical Value Energy

In this approach, we pursue energy minimization by defining the energy theoretically required in facilities and processes as "value energy," and thoroughly eliminating quasi-value and non-value areas through improvements in both facilities and operations.

We are implementing this approach at suppliers as well as Group companies in Japan and overseas.

- Pursuit of Valuable Energy -

Yamaha Motor is using the concept of theoretical value energy as a basis for promoting the reduction of CO2. The concept of theoretical value energy sets out four activitysteps, and reduction activities are carried out based on thesesteps.

■ Theoretical value energy activities

In Step1, the current state of energy for each facility is ascertained and broadly categorized into valuable, quasi-valuable, and worthless.

Worthless and quasi-valuable are considered as improvement targets, and valuable energy is pursued.

■ Processing Facilities Energy Value Classification

| Facility Name | Annual Power Consumption [kW] | Valuable Ratio | Quasi-Valuable Ratio | Worthless Ratio |

|---|---|---|---|---|

| Gear cutter 083-621 | 18,298 | 6% | 34% | 60% |

| Gear cutter 183-015 | 17,765 | 7% | 32% | 61% |

| NClathe 097-782 | 16,054 | 16% | 48% | 36% |

| NClathe 097-796 | 12,180 | 21% | 53% | 26% |

| NCmilling cutter 146-005 | 13,175 | 9% | 40% | 51% |

| Barrel polishing 204-A13-40 | 1,995 | 13% | 81% | 6% |

| Engraver 204-A13-30 | 3,940 | 25% | 70% | 5% |

| Chamfering machine 204-A13-20 | 1,558 | 11% | 45% | 44% |

We will thoroughly consider measures to reduce energy other than valuable energy and make improvements.

■ Value Pursuit Minimization of Hydraulic Energy

■ Processing Facilities Improvement Results

Theoretical Value Energy Activities: Smart Factories Based on Theoretical-Value-Based Production

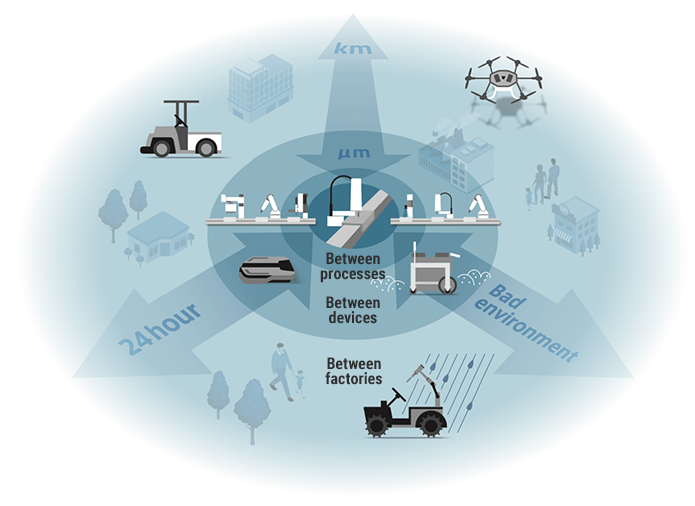

Yamaha Motor is rolling out a smart factory initiative that focuses on time taken by the conveyance tasks and simple tasks that are given a non-value because they do not contribute directly to production in theoretical-value-based production. We are developing a new system of next-generation conveyance connected to linear conveyor modules, compact automatic guided vehicles (AGV) and indoor and outdoor automatic conveyance solutions. These are concepts and technologies that only Yamaha, with its rich experience in robotics and mobility, can conceive of.

Expand Use of Renewable Energy: Setting Targets for the Ratio of Renewable Energy

We are installing power generation systems that use solar and wind power. Following the installation of a solar power generation system at the Main Factory in 2004, these systems have been successively installed elsewhere and the use of renewable energy is expanding. We have extended them to India, the U.S.A, Thailand, Taiwan and elsewhere globally.

With the goal of reducing CO2 emissions by 58% by 2024, along with promoting energy conservation globally and installing energy-saving equipment, we will introduce solar power generation in over 10 countries. To achieve our target, we allocated 2.65 billion yen in the 2023 budget, and intend to increase it to 3.54 billion yen in 2024 to expand the share for renewable energy from the current 3.3% to 9% of the budget in 2024 with the aim of raising that ratio to over 30% by 2035.

Expand Use of Renewable Energy at Production Sites: Introducing CO2-Free Electricity

Since July 2022, we introduced CO2-free electricity generated from hydroelectric power at our major factories in Japan. Thanks to this, the ratio of renewable energy in our energy use is now 27.2%.

Update Facilities, Reform Processes: Installing Energy-Saving Equipment

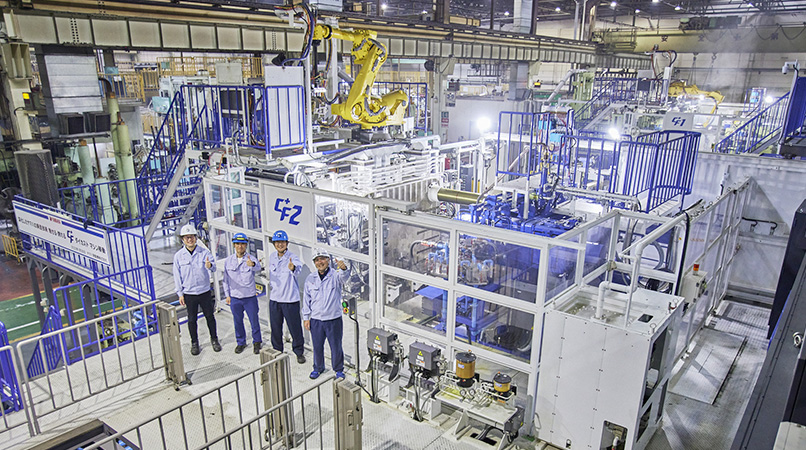

In January 2022, the Main Factory installed new die-cast machines featuring new technologies like ultra high-speed injection and new vacuum technology. We are strengthening our casting technology production systems, one of Yamaha Motor's strengths, to handle increasing requirements for size, complexity and reduced weight in new or electrified products.

![[Example] Ultra high-speed die-cast](./img/2021/fig_007c.png)

Switch from Fossil Fuels to Electricity: Moving Away from Fossil Energy

26.9% of the energy consumed in our production processes comes from fossil fuels, which are mainly used in casting, painting and air conditioning. As part of our drive to be carbon neutral by 2050, we will be changing energy sources from burners to electric heating, from steam to heat pumps and from GHP (gas type) to EHP (electric type).

Reduction of CO2 Emissions in Distribution

We are working to improve transportation efficiency with the aim of reducing CO2 emissions from distribution operations. We are also taking active steps to monitor CO2 emissions from distribution operations at overseas locations in a Groupwide effort to promote reduction activities. In 2023, 413,941 tons of CO2 were emitted globally from distribution operations.