Passed From One Craftsman’s

Hands to Another,

All for Reliability

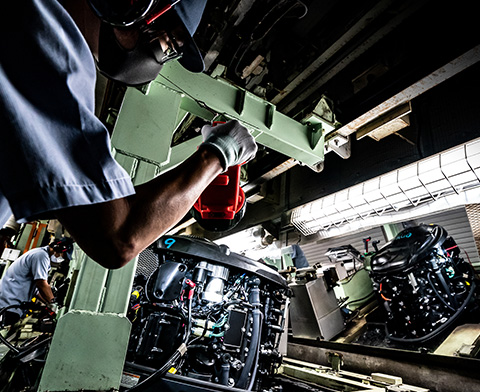

A single outboard motor can sometimes contain up to 3,000 individual components.

From carefully selecting the raw materials to conducting the final inspection, a Yamaha outboard is passed from the hands of one craftsman to another, the culmination of which is the legendary reliability on the water we are known for today.

Aluminum Melt Cleaning Process

Laying the Groundwork for Monozukuri by Hand

If you trace back the various steps of the manufacturing process for building performance, functions, quality, and design into a product, everything begins with the raw materials used. And because delivering unquestionable reliability is the goal when producing Yamaha outboards, the first step in the production process is at aluminum smelting sites.

Aluminum Part Manufacturing

Tough, Intricate, and Beautiful

The lower unit is the bottommost part of an outboard motor and is made from a single large aluminum casting. Its high resistance to corrosion while submerged in the harsh operating environment of the world’s waters is the product of carefully selected materials, precision machining techniques, and the application of a proprietary undercoating using first-rate painting technologies.

Plastic Part Manufacturing

The Beautiful and Trustworthy Face of a Yamaha Outboard

The powerhead cowling envelops the outboard’s engine and it must be well engineered and functional to protect it from the water. But since it doubles as the “face” of the outboard, it must also sport a highly attractive and refined design. To enhance the natural beauty of the cowling’s curves and contours, Yamaha’s craftsmen bring their finely honed senses and skills to bear.

Final Inspection

The Final Steps Ensuring Yamaha’s Signature Reliability

At Yamaha’s outboard motor assembly factory is a series of large water tanks designed to simulate the open sea, and this is where newly completed engines are given their final tests and checks. Every Yamaha outboard engine—without exception—gets its baptism in one of these tanks with a full-throttle test run before being shipped out to countries and waters around the world.