The Extra Steps Producing

Uniquely Yamaha Value

The aesthetic ideals and sense of the Yamaha brand and the pride in our craft drive the finely honed skills and techniques behind the extra steps we take when building our products.

That extra effort to always go a step further is what constitutes Yamaha Motor Craftsmanship.

Engine Assembly via Cell Manufacturing

Hand-Building Engines with Soul

Like a fine watch, each SR400 engine is hand-assembled in its entirety from the ground up by a single craftsman, and even for a worker with highly experienced eyes and hands, the assembly process for a single engine demands a full hour of intense concentration.

Hand-Painted Parts and Bodywork

The Atelier of the Master Hand-Painter

At the paint shops for Yamaha motorcycles manufactured in Japan, robots faithfully reproduce the various techniques honed by craftsmen of paintwork, and are driving automation of the workplace. However, this doesn’t mean that Yamaha has removed the trained sense of these masters from the equation outright; in this now-automated paint shop remains a small atelier for passing on the skills and techniques for spraying on paint by hand.

The Latest in CF Aluminum Die-Casting

Making Large Parts Lighter and More Beautiful

At our aluminum casting worksites, dynamism and delicacy go hand in hand. Everything must be carefully controlled to maintain a delicate balance. Using the latest in casting analysis technology helps ensure each process is optimized.

Yamaha’s SpinForged Wheels

The “Industrial Pottery” Creating Wheels That Are Thin, Strong and Tough

The Yamaha SpinForged Wheels on the new MT-09 were created using a newly developed flow forming process, and as a pioneer in the casting of lightweight aluminum alloy wheels, Yamaha is again opening the door to a new realm of motorcycle chassis manufacturing.

Painting a New Engine Color

For a Sheen Communicating the Intrinsic Qualities of the Metal Itself

The new Crystal Graphite color was meant to create a sheen heavily emphasizing the metal’s innate qualities, with the semi-gloss finish making the engine’s various surface treatments appear even more beautiful.

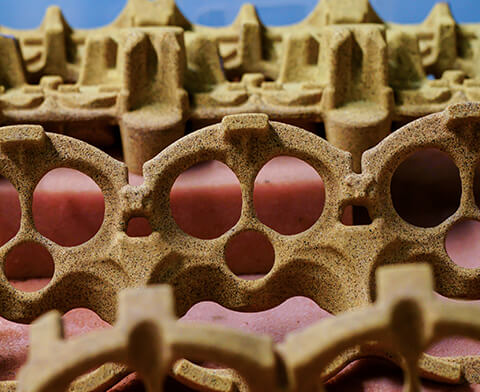

Non-Contact 3D Core Measurement

Ensuring the Precision of Parts That Disappear

Although cores play a critical role in the casting process and directly influence the quality as well as performance of the final piece, said final piece bears no sign that the cores ever existed—they are “disappearing parts.”

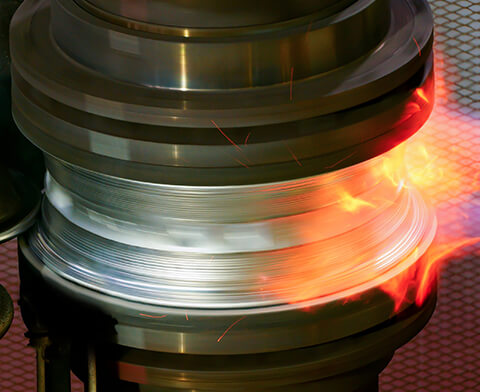

Molding Fuel Tanks

A Constant Clash with Steel to Reach Greater Heights

The MT-09’s fuel tank is composed of complex, interwoven lines and surfaces that create a unique visual character. Fully tapping into the innate qualities and characteristics of the steel plate forming the tank, Yamaha ensures its safety, design appeal and functionality all meet high standards. It is a constant clash with steel to reach greater heights.