High-speed Dispenser YRM-D Feature

High-speed Dispenser for High-density & High-precision Mounting

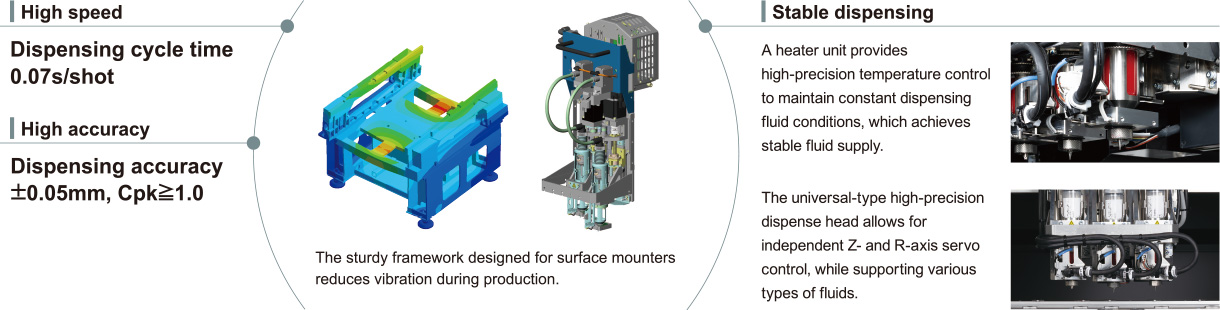

High-speed, High-precision Dispensing

Achieving high-level speed, accuracy, and stability realizes high productivity

Accurate dispensing on various types of PCBs

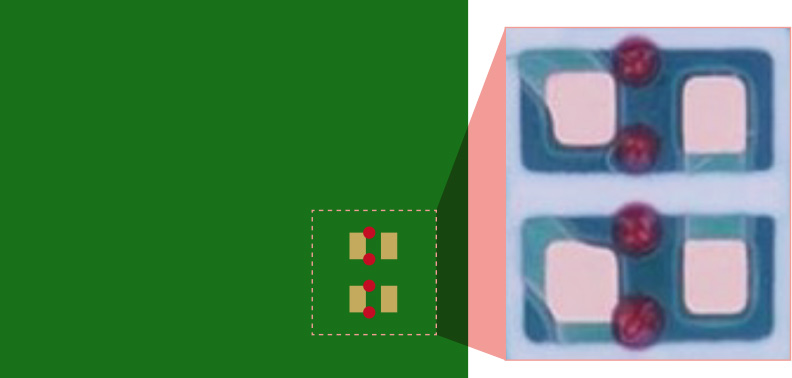

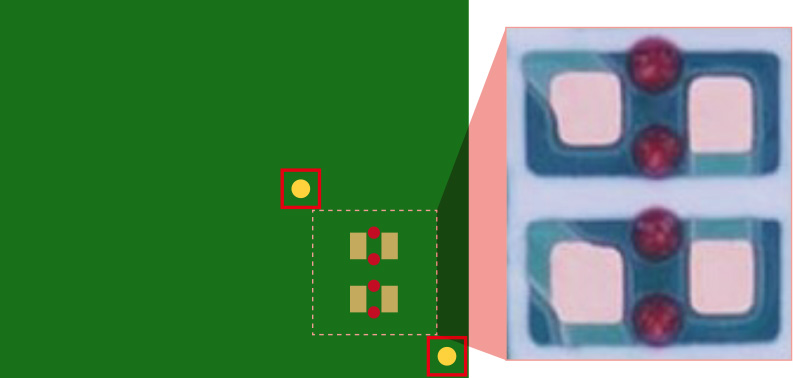

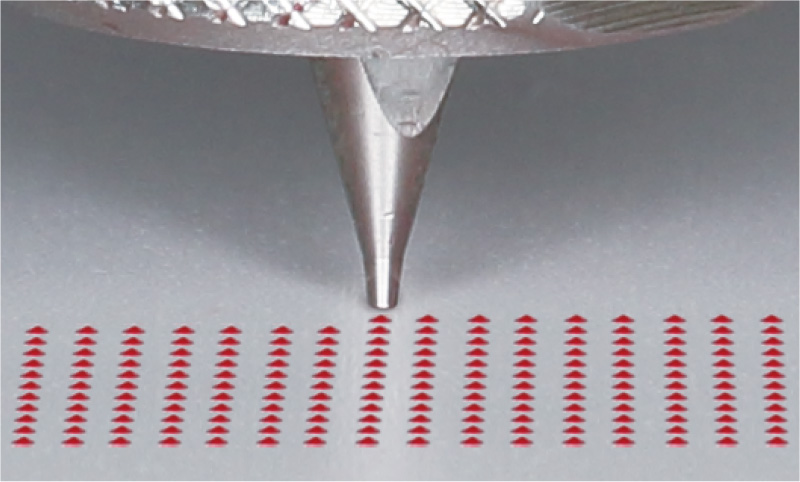

When using multiple production PCBs with transfer pallets, large PCBs prone to generating expansion/contraction and distortion, or paper phenol PCBs, this machine detects multiple marks and locally corrects positions to perform high-precision dispensing.

Position accuracy is low when dispensing on PCBs having poor accuracy, such as large PCBs and paper phenol PCBs.

Setting individual local marks enables high-accuracy dispensing even on PCBs having poor accuracy.

Versatility

Flexibly dispensing on various types of PCBs

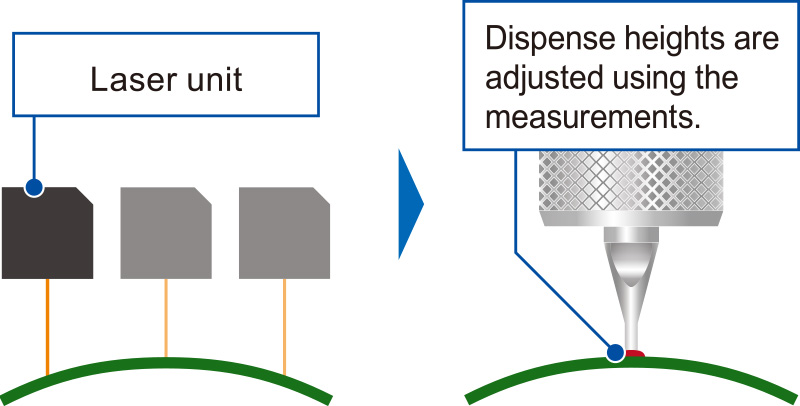

To apply fluids on high-density PCBs that inhibit contact coating, depressions on PCBs, and component mounting PCBs, non-contact dispensing is available. The PCB surface is measured with a laser beam to obtain heights and warps of unevenness, which are reflected in dispense heights to prevent the generation of defects.

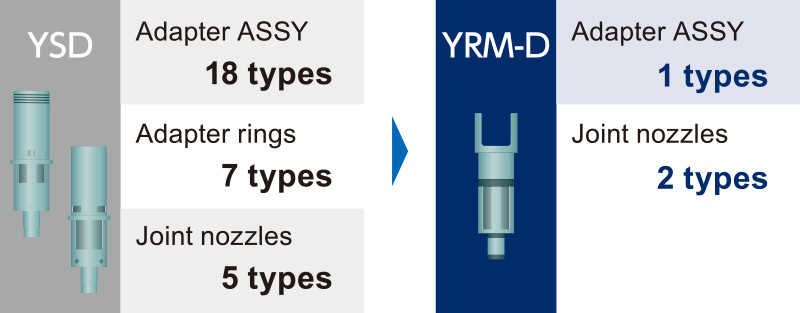

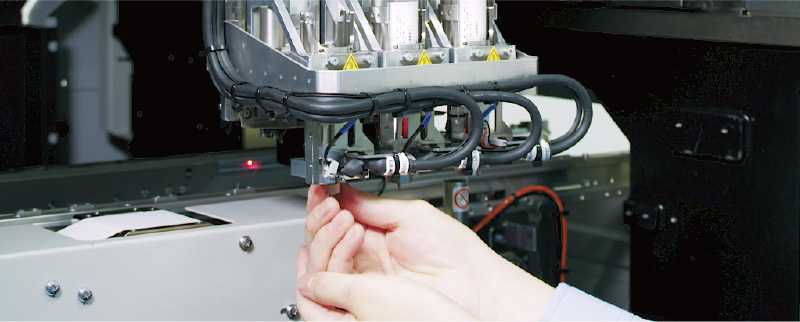

Using common components to improve workability

Compatible with various syringes from 5 to 30 cc. Workload and storage complexity are minimized through the use of common attachments for each manufacturer and each volume.

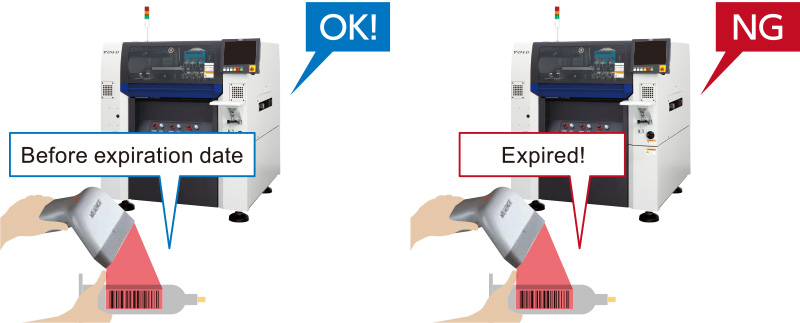

Accurate and reliable control of usage expiration dates

Records storage and retrieval of dispense fluids to accurately control usage expiration dates. Issues cautions to operators during setup and production regarding expiration dates to reliably prevent the use of old fluids.

Labor Savings

Automatic replacement means no setup required

Push-up pins are automatically replaced.

Combined with batch automatic line setup, this simultaneously cuts time and operator workload when changing products.

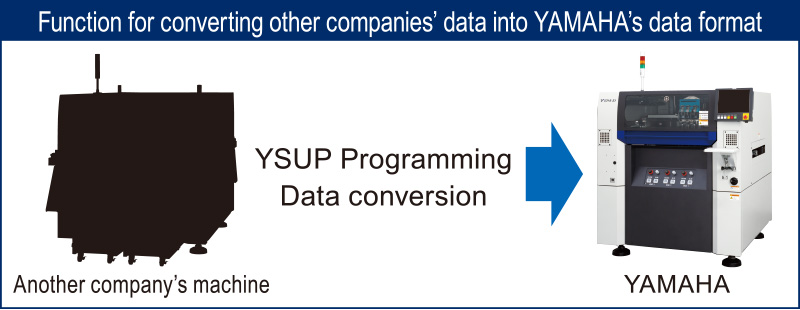

Automatic and easy data generation

Automatically converts CAD data into dispense data. Simplified data generation work reduces the time needed for production preparation.

Automatic correction improves stability

Recognizes the dispensing diameter by pre-dispense to automatically control the dispensing amounts. Minimization of work stabilizes the dispensing accuracy.

Timely and efficient supply

Uses a sensor to detect the remaining amount of dispense fluid in the syringe in order to dispatch an empty alert. Supports replenishment at the appropriate time.

Excellent cleanability shortens cleaning times

The nozzle is directly mounted on the syringe. This makes maintenance tasks such as cleaning easy.

Related contents

- Product

- Introduce our product lineup, including surface mounters, solder printers, and visual inspection machines.

- Showroom

- Find and explore SMT Smart Showroom or Virtual Showroom

- Intelligent Factory

- IoT/M2M Integration system - System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.