Improve your SMT production business’s profitability Quantity x Quality x Labor-saving: SMT solution

Here is the SMT solution you can experience in management work by introducing Yamaha’s SMT equipment.

Speed solution

World-class high-speed heads

Not only mounters but all Yamaha products in Yamaha’s 1 STOP SMART SOLUTION individually realize high-speed production capability.

Building a line with Yamaha products will boost productivity and help to increase sales.

One of the world’s best high-speed heads

One of the world’s best high-speed heads

It’s not only mounters — every Yamaha system is capable of high-speed production.

This means developing a line with Yamaha systems will enable you to complete production quickly, freeing up time for other work.

YRM20 RM head/high-speed mounting

YSP10 / High-speed printing

YRi-V / High-speed 3D inspection

Quality solution

Wide-ranging features and lineup to improve the three major losses

In SMT production businesses, delivering defective products to customers and the market will result in huge losses aside from just cost.

Such losses can include those from wasting components and shutting down equipment. Yamaha offers a rich array of features and a comprehensive equipment lineup that helps you solve those problems.

Extensive lineup of inspection machines to minimize defects leaving the plant

Extensive lineup of inspection machines to minimize defects leaving the plant

Inspection machines offer many optional settings for both AOI and SPI, forming the heart of the 1 STOP SMART SOLUTION.

You can choose options according to the needs for your line, such as an economical combination of just 2D inspection for AOI and one projector for SPI, or a fully equipped high-performance option.

3D Hybrid Optical Inspection System YRi-V

3D High-speed Solder Paste Inspection Machine YSi-SP

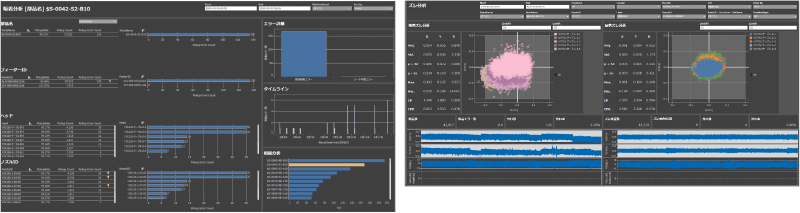

Improves pickup rate with loss-cost analysis, significantly reducing component waste

Improves pickup rate with loss-cost analysis, significantly reducing component waste

An efficient way to improve the pickup rate is to start with components that cause many of the pickup errors. But Yamaha also incorporates a cost perspective to propose effective orders of priority, calculated from the number of pickup errors and component costs, and from the perspective of waste cost.

Analysing Dashboard

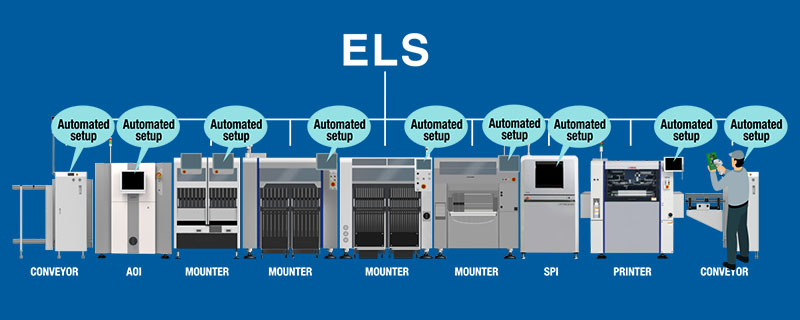

Comprehensive automatic setup features minimize line stoppages

Comprehensive automatic setup features minimize line stoppages

Setup work for high-mix production may cause significant losses due to line stoppage.

Yamaha has developed an extensive range of automatic setup features for every piece of equipment to minimize stoppages from setup work.

Automating the setup tasks also minimizes human error, improving quality and production efficiency.

ELS: Automatic setup

Printer: Fully automatic setup

Printer: Automatic push-up pin exchange

Mounter: Auto nozzle changer

Resource solution

Production progress management & reporting

To manage SMT production properly, you need to be able to accurately grasp the state of the production floor.

1 STOP SMART SOLUTION uses software to collect various data, enabling you to check the state of production at any time.

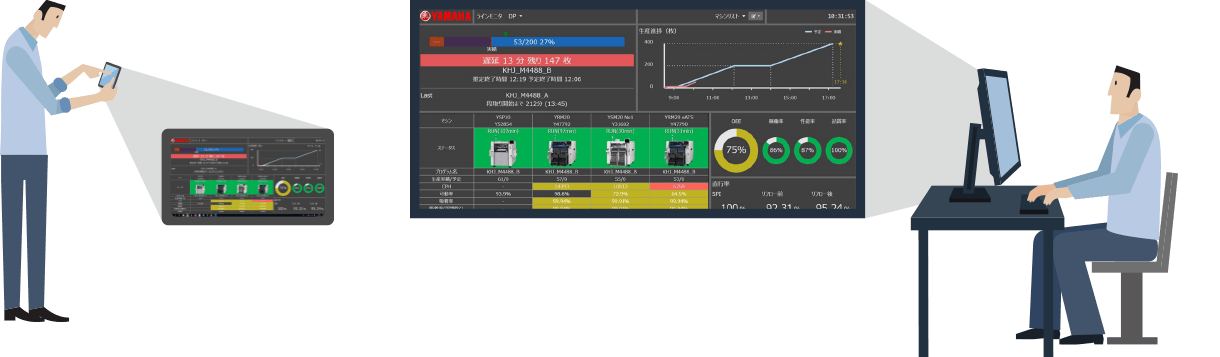

Visualizing your production floor

Visualizing your production floor

You need to be able to check the state of the work site at a glance to see whether production is going according to the plan and whether quality is meeting the standard. Adopting visualization software enables you to check the production status, such as progress, from anywhere without interfering with the work itself.

Live Dashboard

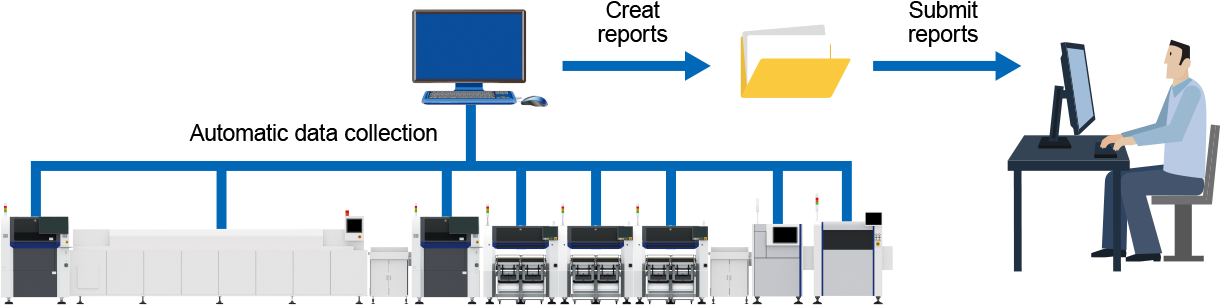

Simplifying data aggregation, and reporting

Simplifying data aggregation, and reporting

Creating monthly reports about whether there were any problems with production, etc. places a burden on staff at your site. 1 STOP SMART SOLUTION eases this load by creating reports and automatically collecting data, minimizing the time your personnel spend on creating reports.

Analysing Dashboard

Related contents

- Product

- Introduce our product lineup, including surface mounters, solder printers, and visual inspection machines.

- Intelligent Factory

- IoT/M2M Integration system - System allows linking our SMT machines to equipment made by other companies and give all-around high productivity in the mounting process.

- Showroom

- Find and explore SMT Smart Showroom or Virtual Showroom

- Model Lineup

- The following showcases our lineup of models that solve customers' issues.