An agreement to cooperate on technology for sports car production was concluded between Toyota and Yamaha on September 8, 1965. However, in December of the previous year, a joint development project had already started for the Toyota 2000GT.

Toyota handled the overall layout and design for the car, along with the basic parameters, while Yamaha, under the direction of Toyota, was primarily responsible for improving engine performance and for detailed design of the body and chassis. The average age of the development team was around 30. Although all of the members had an above-average interest in cars, they had next to no knowledge or experience when it came to manufacturing them.

Development proceeded with the aim of exhibiting the car at the Tokyo Motor Show in October 1965. The 2000 cc, inline 6-cylinder engine, which was originally installed in the Toyopet Crown, was converted to a DOHC layout in an effort to substantially raise its output. In addition, the cylinder head covers were given a matte black wrinkle finish. Among Japanese automobiles at the time, there were very few instances of applying design features that were commonplace on motorcycles with exposed engines to car engines hidden under the hood.

There were many firsts involved in creating the body designs and prototypes. Based on Toyota's basic design, the team created full-size diagrams and produced wood grids for the sheet metal. For the hood and trunk lid, Yamaha leveraged handcrafting FRP molding techniques, which had been cultivated in the company's boat manufacturing activities. For the roof, fenders, doors, and other components, prototypes were created by shaping sheet metal with the skill of an artisan. Interior components like the steering wheel, gearshift knob, and instrument panel were made of wood. Advanced techniques were required to prevent splitting and cracking in the natural wood used inside the car. Such cracking could potentially have occurred when the wood was exposed to especially hot summer weather. The team, though, resolved the problem by utilizing woodworking techniques developed in Yamaha's musical instrument business. Advanced technologies were also required in various other areas, including the cast magnesium disc wheels and the hand-sprayed body paint.

The prototype was completed by incorporating the most cutting-edge, advanced technologies available at the time. It was presented at the Tokyo Motor Show in 1965 as the Toyota 2000GT.

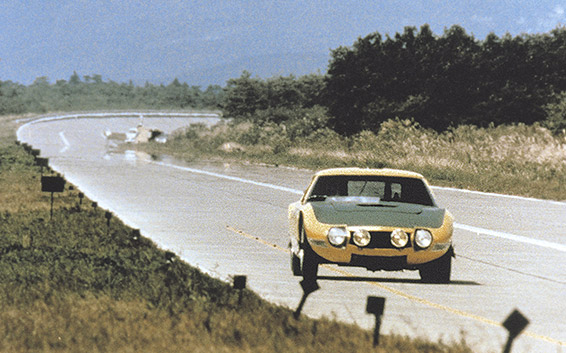

Production of the 2000GT as a commercial automobile was started at the new Iwata Factory, where phase one construction had been completed. There really was very little difference, though, between the actual production process and that used to create the prototype. Although considered "mass production," the process actually involved assembling each car by hand, one by one. Production of the body, in particular, proceeded through trial and error-on the operating mechanism, for example, for the curved glass windshield, a first for a domestically produced automobile, and on matching the colors of paint used on parts made of FRP and sheet metal.

In addition, there was a final inspection that had to be passed in order for the car to be marketed to the public. Toyota's inspection standards were extremely strict, and the 2000GT had trouble meeting them. It was particularly hard to eliminate water leakage and the squeaking sound of the wiper blades. Each problem, though, was solved one at a time, and the first market-ready model was completed in February 1967.

.