On November 7, 1953, a confidential directive was given to the executive officers of Nippon Gakki, the forerunner of YMC, by President Genichi Kawakami. The directive instructed the company to produce a prototype motorcycle engine. This required working with some five or six types of engines and selecting one from that group to develop into a product. The goal was to launch full-scale production in one year.

In the 1950s when Japan was first embarking on the road to recovery, there were countless companies entering the motorcycle industry. At one point, the number of companies swelled to 204. However, a shakeout had already begun by the time President Kawakami suggested producing motorcycles, and there were some doubts in the company about whether it would really be possible to be successful entering the market so late in the game.

Explaining his decision some time later, President Kawakami said, “There were people who were skeptical about going into the motorcycle business at that time. Nonetheless, we launched the business with the conviction that this would be the best step for the company given my own tour of Europe and the results of research done by the director of engineering and others.” He also explained that the issue of wood resources placed limits on increasing production of musical instruments and that the musical instrument business would not be so easy in the future. President Kawakami made it clear that he was betting that motorcycles would provide a springboard for the company’s future growth.

The company had decided to enter the motorcycle business, but struggled with selecting a model to pattern development after. Several types of European motorcycles were proposed as candidates and deliberations continued right up until the deadline. In the end, the decision was made to begin production based on the RT125, a 125 cc motorcycle built by the German company DKW. The RT125 was famous for having been copied more often than any other motorcycle in the world.

Development began on a prototype right away, but as can be expected in any project that is being taken on for the first time, Nippon Gakki encountered many difficulties. For example, the first cylinders, which were developed based on a casting technique used to make piano frames, looked like lumps of steel and were jokingly referred to as teapots. What’s more, because the casting process used sand molds, the finish fell far short of the elegant fins produced by DKW. The engine basically followed DKW’s design, but the company incorporated original design elements as well, making the transmission four gears instead of three and putting the gear-change pedal and kickstart pedal on the same axle. The starting mechanism was the first in Japan to employ the primary method, which enables the engine to be started no matter what gear the bike is in as long as the clutch is disengaged. This was a groundbreaking development that made the motorcycle easier to operate. These technical features also clearly distinguished it from the RT125, the model on which it was based.

Most of the world’s motorcycles at the time were black, but the new bike used a novel two-tone color scheme with cream and a reddish-brown reminiscent of the chestnut coat of a fine horse. Thanks to this and other features such as its engine, which would always start with a light kick, its sharp acceleration, and its comfortable handling, the bike earned the nickname Akatombo, or “Red Dragonfly.” The color scheme was developed by students belonging to a group called “GK” (Group of Koike) led by Assistant Professor Iwataro Koike at Tokyo National University of Fine Arts and Music.

During this period, President Kawakami could usually be found on the production floor providing leadership. He even personally assembled engines and took part in test drives of the prototypes. He also participated in a durability test over 10,000 kilometers on public roads around Lake Hamana. This kind of test was unprecedented for motorcycles in those days.

On February 11, 1955, the long-awaited first YA1, a motorcycle with a 2-stroke air-cooled 125 cc engine, was completed and shipped from Nippon Gakki’s newly built Hamana Factory.

Immediately after the first motorcycle rolled off the line, the director of the engineering department himself mounted the bike to deliver it to the sales branch in Hamamatsu. The factory shut down for a short time, and he was seen off by the entire workforce of 80 employees, who lined up on both sides of the front entrance. The time from the start of development to the first delivery was a surprisingly short eight months. President Kawakami would always tell his workers that working carefully meant working quickly, and this truly was the practical manifestation of his words.

Salespeople assigned to YMC outlets within Nippon Gakki’s network of branch offices rushed out with sample bikes, making the rounds to exclusive dealers of other companies, motorcycle dealers, and bicycle shops in an attempt to acquire distributors. Negotiations proved difficult, however, because YMC was a latecomer to the market, and exclusive dealers, which were regarded as the top regional outlets, already had close ties with established manufacturers in the market. Moreover, whereas the average price of competing motorcycles in the 125 cc class was 110,000–120,000 yen, the YA1 was priced at 138,000 yen. Although the company had absolute confidence in its quality, the new motorcycle did not sell very well in the initial period following its launch.

Despite the difficulties, the number of outlets selling the YA1 gradually increased and production eventually began to pick up as more and more people became aware of the bike’s novel color scheme and design, its light weight and easy maneuverability, and its good start-up performance, which was an extremely important feature at that time.

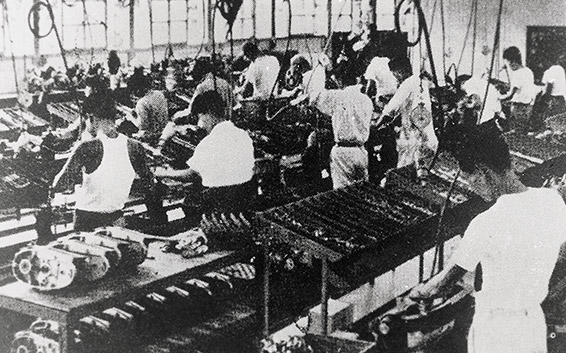

On July 1, 1955, the motorcycle manufacturing department was spun off from Nippon Gakki, and Yamaha Motor Co., Ltd. was established. The new company was headquartered in Hamakita, Shizuoka Prefecture and capitalized with 30 million yen. Genichi Kawakami served as its president. YMC started with a monthly production target of 200 units, a workforce of around 150, and a factory consisting of two wooden one-story buildings.

.