Yamaha Motor to Present at 2023 International Robot Exhibition under the theme "Transportation"- Proposing the automation of transportation from beginning to end that connects factories internally and externally, from microns to kilometers -

October 30, 2023

IWATA, October 30, 2023 - Yamaha Motor Co., Ltd. (Tokyo: 7272) announced today that the company will attend the world's largest robot trade show 2023 International Robot Exhibition (iREX2023) at the Tokyo Big Sight from Wednesday, November 29th to Saturday, December 2nd (Organizer: Japan Robot Association, Nikkan Kogyo Shimbun Ltd.) The company will exhibit various products and services at the show under the theme of "Transportation."

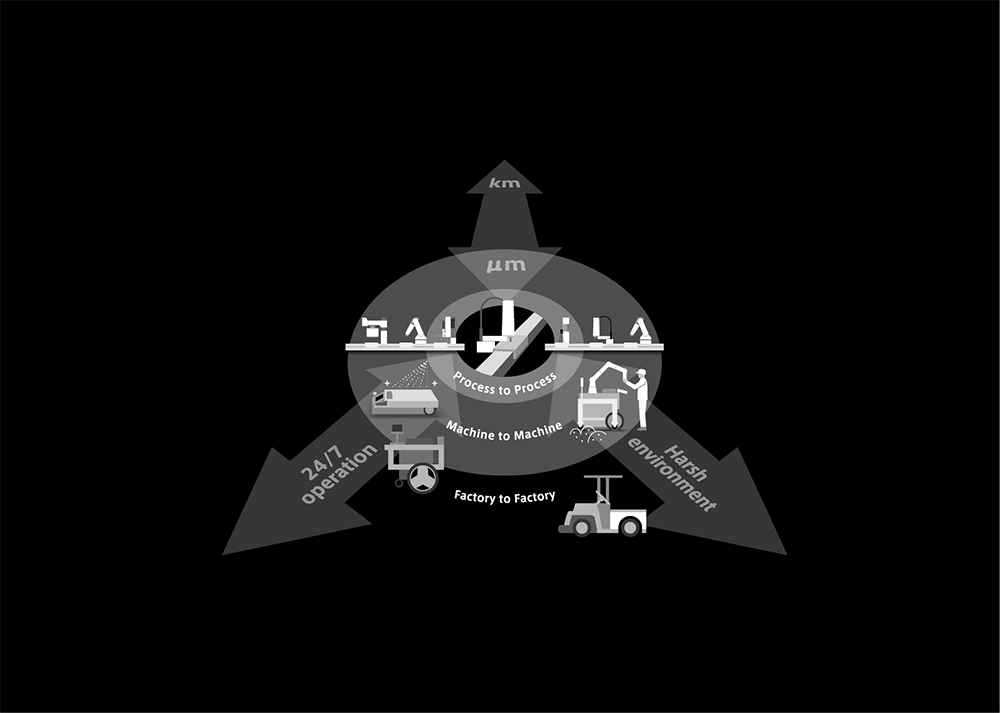

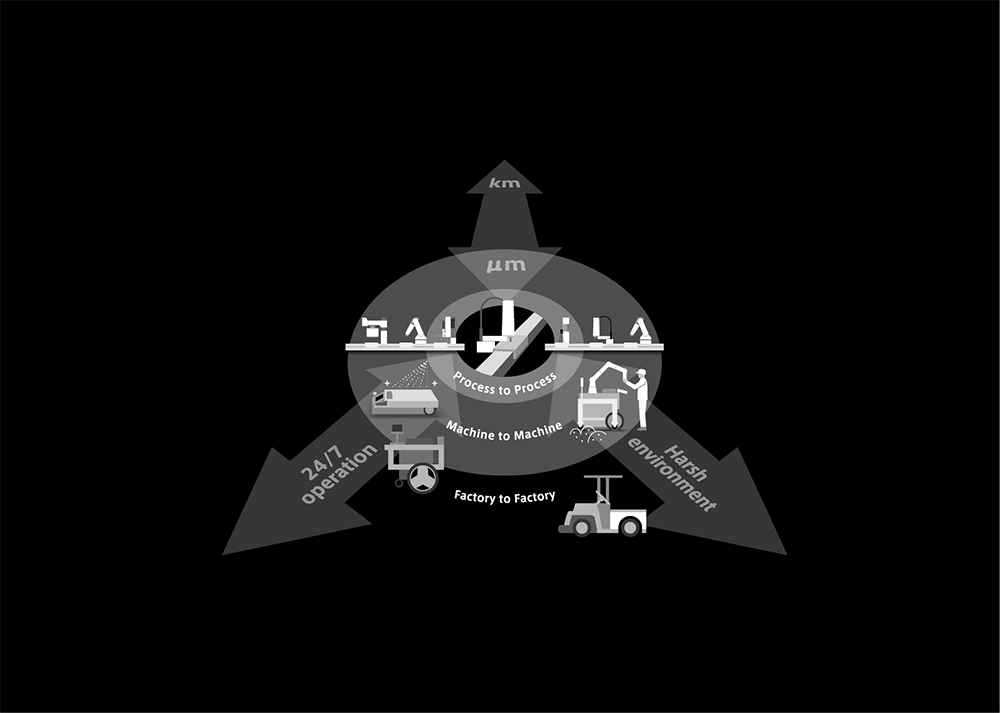

The exhibition concept is "μ to km (microns to kilometers) ~ Robotics Transportation ~," continuing from the previous year. With concepts and technologies unique to Yamaha Motor, which has a wealth of experience in the robotics and mobility businesses, the Company offers new styles in next-generation transportations that connect linear conveyor modules, and small AGVs (automated guided vehicles) for both indoor and outdoor use.

Robotics and intellectual technology are technical areas that Yamaha Motor position as the foundation for the realization of the company's long-term vision "ART for Human Possibilities" ~ Let's strive for greater happiness~. Yamaha Motor is aiming for solutions that automate work related transport and simple tasks, which are considered worthless because they do not directly contribute to production activities, and allow people to work smarter.

■ 2023 International Robot Exhibition Online Venue Yamaha Motor Booth

https://irex.nikkan.co.jp/booth/yamaha-motor

*The online venue will be held from November 22nd (Wednesday) to December 15th (Friday).

*Free of charge, pre-registration required

■ Yamaha Motor International Robot Exhibition - Special Site

https://www.yamaha-motor.co.jp/robot/event/2023irex/

Transport accelerates the future of automation.

Yamaha Motor has been focusing on the transportation of goods as a means of solving the shortage of human resources in the manufacturing industry.

At the 2023 International Robot Exhibition, we will offer solutions that enable transportation in various environments, from precision positioning in μ units to movement between devices, processes, and km between factories.

Yamaha Total Solution Line Demonstration Machine

(LCMR200 Linear Conveyor Module)

This is a next-generation transport platform that significantly increases line productivity through the combination of fast speed x circulation & diversification. The ALL YAMAHA line equipment demonstration machine based on the LCMR200 linear conveyor module, combined with various Yamaha products such as SCARA robots, robot vision cameras, single-axis robots, and pick & place robots, will be exhibited for the first time. Furthermore, we will be exhibiting numerous demonstration machines based on the LCMR200.

SCARA Robot Parts Feeder Demonstration Machine

This is a collaboration demonstration machine that combines the arc tracking function*¹ added to the RCXiVY2+ Yamaha Robot Vision with rotating-parts feeder and vibrating-parts feeder*². This machine will achieve both labor-saving and picking operations with higher precision.

*1 Function which the SCARA robot follows a workpiece on a rotary table or other turntable with a circular movement

*2 Parts feeders are non-Yamaha products

YK-XEC Series SCARA Robot Clean Type / Large-sized Type <Large-sized type is ref. exhibit>

Clean SCARA robots, which are ideal for pharmaceutical and food production sites and achieve high speed and low cost, and large SCARA robots, which are in rapidly growing demand in the automotive industry, will be exhibited. A demonstration of the operation will be carried out at the venue.

Assembled Toughness AGV: COW-el (Ref. exhibit)

COW-el automated transport machine is available in two series: AGV and AMR. By combining them with various modules, it achieves high versatility. This year's exhibition will feature the Collaborative Robot x AGV, which combines a collaborative robot with Toughness AGV with high environmental resistance, a quiet and compact AMR, and washableAGV that can be used in harsh environments. The COW-el, which can be adapted to a wide range of environments depending on the combination, is expected to be used in a variety of scenarios, not limited to use in factories.

COW-el AGV

FG-01 EV for Automatic Transportation in Indoor and Outdoor Use

This is an autonomous automated transportation machine that can travel in outdoor environments with wind and rain, as well as slopes and steps. Developed based on our land cars, which have a history of about nearly half a century, it demonstrates high driving performance and technical reliability. eve autonomy, a joint venture established by Yamaha Motors and TIER IV, provides eve auto, an automated transportation service with TIER IV's automated driving technology in the FG-01. Automated driving within the factory premises contributes to solving issues such as labor shortages and ensuring safety.

Surface Mounters

Enables high-speed and high-precision operations. This machine automates operations for compact precision components, which were carried out manually using microscopes to date. Yamaha Motor's booth will feature a demonstration machine for high-speed seal application that combines the YS12 surface mounter with a feeder*³ that supplies the seals and its reel.

*3 Feeders are non-Yamaha products

7-axis Collaborative Robots (Ref. exhibit)

Equipped with high-precision force sensors on all axes, it combines precision motion with a high level of safety, enabling highly accurate force control. Through the adoption of seven axis, it is possible to work in a narrow area, and in addition to the low-speed operation of a general collaborative robot, it also has a high-speed operation mode.

Other (Demonstration of centralized indoor-outdoor transport / exhibition of various SCARA robot machines)

At the Yamaha Motor booth, a transport demonstration will be held, in which workpieces carried by the FG-01 automated transportation EV will be received by the COW-el collaborative robot x assembled Toughness AGV, and fed into an inspection machine consisting of the LCMR200 linear conveyor module, SCARA robots, vision system and other equipment. We will also be presenting various SCARA robots at the booth.

■Contact us from the Press

Corporate Communication Division, PR group: +81-538-32-1145

■News Center: https://global.yamaha-motor.com/news/

The exhibition concept is "μ to km (microns to kilometers) ~ Robotics Transportation ~," continuing from the previous year. With concepts and technologies unique to Yamaha Motor, which has a wealth of experience in the robotics and mobility businesses, the Company offers new styles in next-generation transportations that connect linear conveyor modules, and small AGVs (automated guided vehicles) for both indoor and outdoor use.

2023 International Robot Exhibition Yamaha Motor Booth (Image)

Robotics and intellectual technology are technical areas that Yamaha Motor position as the foundation for the realization of the company's long-term vision "ART for Human Possibilities" ~ Let's strive for greater happiness~. Yamaha Motor is aiming for solutions that automate work related transport and simple tasks, which are considered worthless because they do not directly contribute to production activities, and allow people to work smarter.

■ 2023 International Robot Exhibition Online Venue Yamaha Motor Booth

https://irex.nikkan.co.jp/booth/yamaha-motor

*The online venue will be held from November 22nd (Wednesday) to December 15th (Friday).

*Free of charge, pre-registration required

■ Yamaha Motor International Robot Exhibition - Special Site

https://www.yamaha-motor.co.jp/robot/event/2023irex/

<Purpose of exhibiting>

Transport accelerates the future of automation.

Yamaha Motor has been focusing on the transportation of goods as a means of solving the shortage of human resources in the manufacturing industry.

At the 2023 International Robot Exhibition, we will offer solutions that enable transportation in various environments, from precision positioning in μ units to movement between devices, processes, and km between factories.

<Major exhibit models>

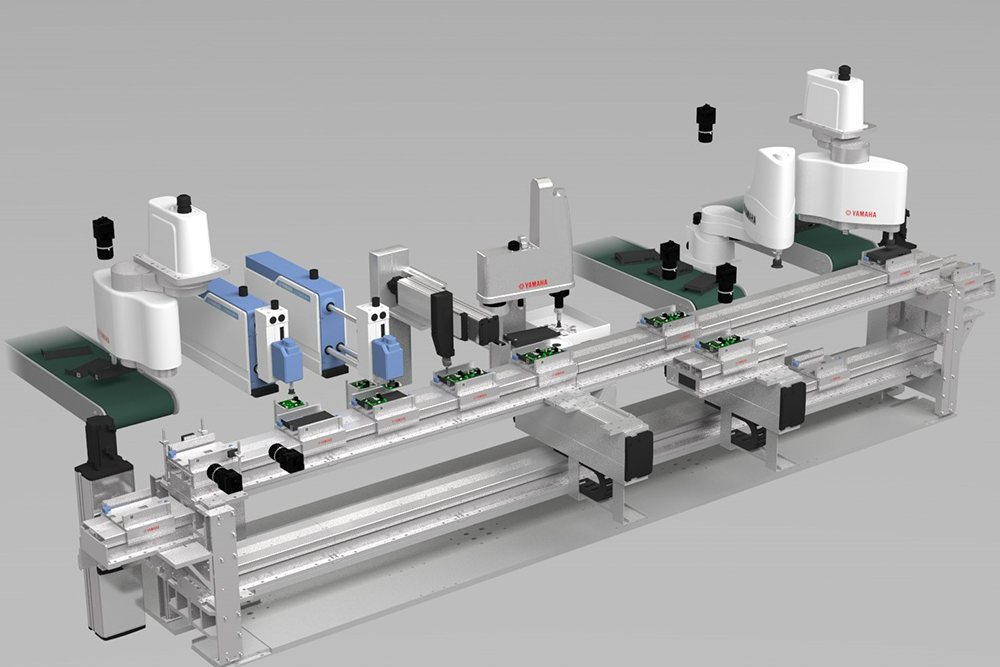

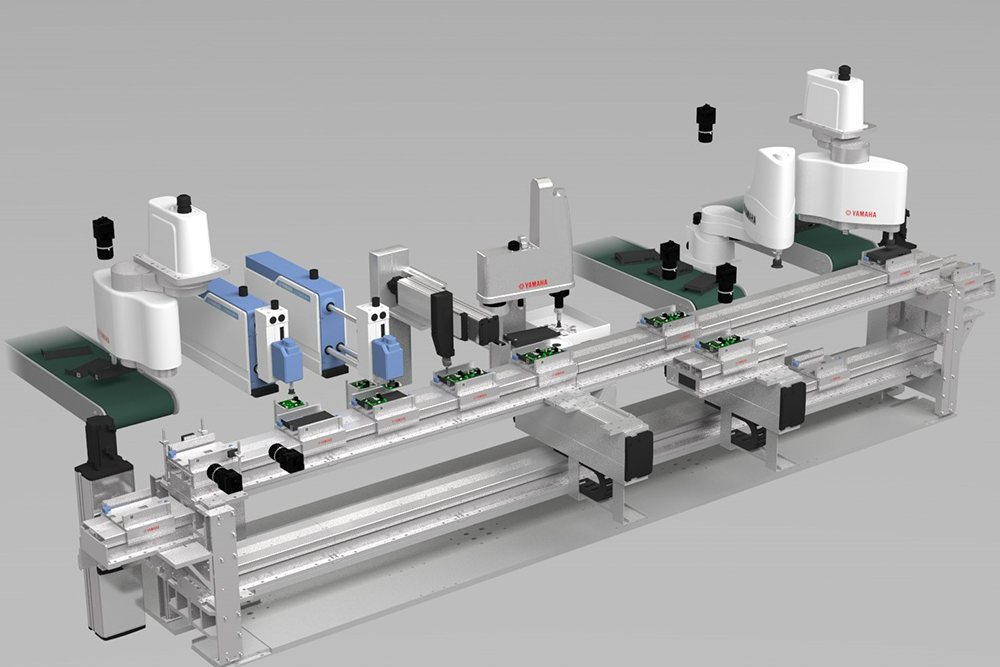

Yamaha Total Solution Line Demonstration Machine

(LCMR200 Linear Conveyor Module)

This is a next-generation transport platform that significantly increases line productivity through the combination of fast speed x circulation & diversification. The ALL YAMAHA line equipment demonstration machine based on the LCMR200 linear conveyor module, combined with various Yamaha products such as SCARA robots, robot vision cameras, single-axis robots, and pick & place robots, will be exhibited for the first time. Furthermore, we will be exhibiting numerous demonstration machines based on the LCMR200.

Image of LCMR200

SCARA Robot Parts Feeder Demonstration Machine

This is a collaboration demonstration machine that combines the arc tracking function*¹ added to the RCXiVY2+ Yamaha Robot Vision with rotating-parts feeder and vibrating-parts feeder*². This machine will achieve both labor-saving and picking operations with higher precision.

*1 Function which the SCARA robot follows a workpiece on a rotary table or other turntable with a circular movement

*2 Parts feeders are non-Yamaha products

Circular tracking function image

YK-XEC Series SCARA Robot Clean Type / Large-sized Type <Large-sized type is ref. exhibit>

Clean SCARA robots, which are ideal for pharmaceutical and food production sites and achieve high speed and low cost, and large SCARA robots, which are in rapidly growing demand in the automotive industry, will be exhibited. A demonstration of the operation will be carried out at the venue.

YK-XEC Series

Assembled Toughness AGV: COW-el (Ref. exhibit)

COW-el automated transport machine is available in two series: AGV and AMR. By combining them with various modules, it achieves high versatility. This year's exhibition will feature the Collaborative Robot x AGV, which combines a collaborative robot with Toughness AGV with high environmental resistance, a quiet and compact AMR, and washableAGV that can be used in harsh environments. The COW-el, which can be adapted to a wide range of environments depending on the combination, is expected to be used in a variety of scenarios, not limited to use in factories.

COW-el AGV

FG-01 EV for Automatic Transportation in Indoor and Outdoor Use

This is an autonomous automated transportation machine that can travel in outdoor environments with wind and rain, as well as slopes and steps. Developed based on our land cars, which have a history of about nearly half a century, it demonstrates high driving performance and technical reliability. eve autonomy, a joint venture established by Yamaha Motors and TIER IV, provides eve auto, an automated transportation service with TIER IV's automated driving technology in the FG-01. Automated driving within the factory premises contributes to solving issues such as labor shortages and ensuring safety.

FG-01

Surface Mounters

Enables high-speed and high-precision operations. This machine automates operations for compact precision components, which were carried out manually using microscopes to date. Yamaha Motor's booth will feature a demonstration machine for high-speed seal application that combines the YS12 surface mounter with a feeder*³ that supplies the seals and its reel.

*3 Feeders are non-Yamaha products

7-axis Collaborative Robots (Ref. exhibit)

Equipped with high-precision force sensors on all axes, it combines precision motion with a high level of safety, enabling highly accurate force control. Through the adoption of seven axis, it is possible to work in a narrow area, and in addition to the low-speed operation of a general collaborative robot, it also has a high-speed operation mode.

Other (Demonstration of centralized indoor-outdoor transport / exhibition of various SCARA robot machines)

At the Yamaha Motor booth, a transport demonstration will be held, in which workpieces carried by the FG-01 automated transportation EV will be received by the COW-el collaborative robot x assembled Toughness AGV, and fed into an inspection machine consisting of the LCMR200 linear conveyor module, SCARA robots, vision system and other equipment. We will also be presenting various SCARA robots at the booth.

■Contact us from the Press

Corporate Communication Division, PR group: +81-538-32-1145

■News Center: https://global.yamaha-motor.com/news/