Newsletter:Making Factories Easier to Work at from a Woman's Perspective --Rising Expectations for Women to Shine Brighter in the Ever-Changing Field of Manufacturing--

September 25, 2023

■Improving the Workplace for Everyone through Ergonomics

From the results of bettering work environments through ergonomics, Yamaha Motor is moving forward with increasing the ease of reach and levels of automation for each line task. This has led to processes previously handled solely by men becoming doable by women and older workers.

Yamaha Motor aims to be a company where a diverse workforce plays an active role and has initiatives underway to bring greater diversity and inclusion to each workplace. Of course, manufacturing and production sites are no exception.

Kanoko Oishi works on an assembly line for outboard motor parts, and through collaborating with other women leaders in her workspace, she has been striving to improve their environment through ergonomics that quantifies the loads placed on the body. "After two years of working on improvements, we've been able to really expand the range of duties that women and older operators can handle," she says.

What formed the basis of the improvements made by Oishi and her colleagues was measuring the loads subjected to seven body parts that move when working on the line (neck, shoulders, waist, knees, elbows, wrists, and fingers) and evaluating them on a scale of 1 to 10. For example, when picking parts from a shelf, the load placed on the body is quantified, e.g., an elbow angle of 160° is 7, a neck angle of 35° is 7, and a wrist angle of 20° is 3. These values were closely examined and vetted, including the differences recorded between men and women operators when performing the same movements.

A total of 7,000 items were subject to evaluation for each line. In response to the issues that arose, detailed and well thought out improvements were implemented to facilitate easier reach by operators or opting for greater automation, such as altering shelf angles or rearranging jig placement. As a result, many women and seniors are now part of assembly processes that were previously only performed by men in the prime of their careers.

Over the past few years, the globe-spanning pandemic and resulting disruption of supply chains has required production sites to adapt to drastic industry changes and constantly fluctuating situations. From that perspective, creating an environment where anyone can work effectively and complement each other's capabilities is also connected to enhancing greater adaptability of the workplace as a whole.

■HR Development Initiatives Driving Our Digital Transformation

The ratio of women at Yamaha Motor production sites is under 10% companywide, and since most of them work on assembly lines, Ayumi Shima is a rarity as she has experience working in a machining factory. The company has high hopes for her as she promotes DX with a keen awareness of what it is like to work on the factory floor.

On the other hand, there are also women actively working to expand the scope of their roles through the company's internal programs. "When I returned to work after my maternity leave, I was taken aback by how far digitalization had come at my workplace," admits Ayumi Shima, who is currently enrolled in an "in-house study abroad" program that has placed her in the Data Sensing Technology Development Group. Until she left for maternity leave, Shima worked in the machining workshop of an engine parts factory, which is basically dominated by men due to requiring night shifts and some tasks requiring workers to lift heavy jigs and the like.

Such production sites are currently undergoing rapid changes to transform into smart factories. The in-house program Shima and others are participating in has an enrollment period of two years and is an initiative to nurture future human resources that will play active roles in factories of the near future where automation and digital transformation (DX) is well underway. "I'm not much of a computer person, so I wondered at first if I would be the right fit, but I'm taking on the challenge of systems development relying on the support of everyone around me," says Shima. As a result of her work, the processing of casting mold repair request forms, which had previously all been done by hand, was successfully digitalized with the system she developed and introduced.

"My strength is that, on the one hand, I have real experience working on the factory floor. If I can put IT skills and more digital-based approaches in my other hand, I think I can contribute to solving problems in the field as an 'ambidextrous' promoter of DX," posits Shima. With her knowing the heat of the machining workshop, the smell of cutting oil, the fatigue that comes from working night shifts, and more, she is armed with real-world experience that can lead to unique solutions.

A task team of women active in Yamaha factories was formed in order to improve worksites by making them easier to work at with ideas from a woman's perspective. The team is making various proposals for worksites to consider implementing.

Message from the Editor

Since its founding in 1955, Yamaha Motor has long considered women as part of the workforce. In Japan at the time, factories were by and large considered a man's workplace, but Yamaha made some creative alterations to tasks and processes to create positions for women as well. In those days, it was rare to see women working in factories and the press often visited our facilities to report on the development. In the latter half of the 1970s when the Passol 50cc commuter model was released specifically targeting women, the production line for the scooter was staffed entirely by women and it became quite the headline.

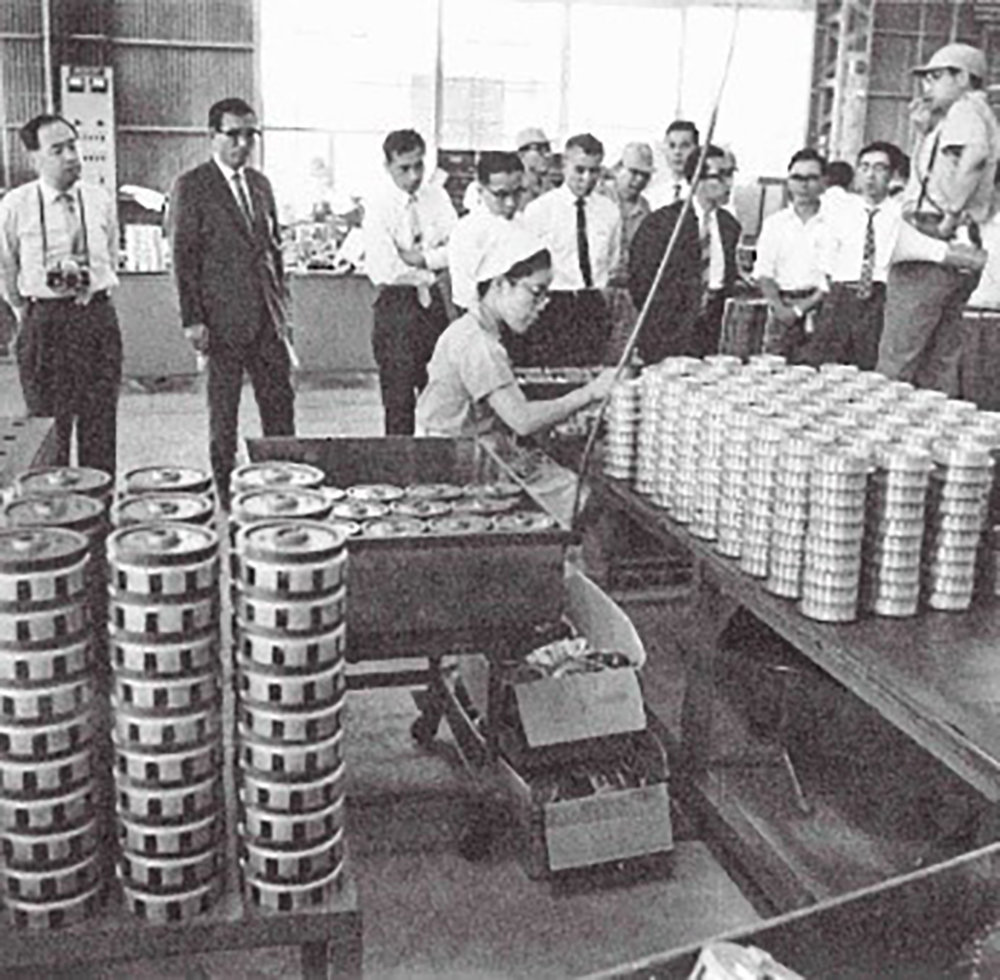

The press interviewing women working in the factory in the 1960s

Similarly, the Cygnus Ray launched in India in 2019 was done so under the vision of supporting the social advancement of women in line with the country's own economic development, and the Cygnus Ray's assembly line was also run entirely by women.

TOKUTOME, Yayoi

■Contact us from the Press

Corporate Communication Division, PR group: +81-538-32-1145

■News Center: https://global.yamaha-motor.com/news/