Yamaha Motor Adopts Plant-Derived Next-Generation Materials for Personal Watercraft and Sports Boats - World's first mass-produced parts for vehicles -

August 25, 2023

IWATA, August 25, 2023 - Yamaha Motor Co., Ltd. (Tokyo: 7272) announced today that it has adopted plant-derived cellulose nanofiber (CNF) reinforced resin for parts in its 2024 models of WaveRunner personal watercraft and sports boats, both using water-jet propulsion devices, as an initiative toward reducing CO₂ emissions and the Company's environmental footprint, and that sales of these models have begun in North America. This is the world's first*¹ case of mass-producing parts for vehicles using this material.

The CNF reinforced resin part being mass-produced is the engine cover*² for power units and was developed in collaboration with Nippon Paper Industries Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo). Yamaha Motor is also examining the greater use of various cellulose fibers not only in marine products but also in motorcycles and a wide range of other Yamaha products in the future.

CNF reinforced resin is a new high-strength material manufactured by kneading and dispersing CNF, a biomass material made from wood resources, into resins such as polypropylene. In addition to being over 25% lighter than existing resin materials, it also has excellent material recyclability, leading to a reduction in the amount of plastics used and greenhouse gas emissions, mainly CO₂.

In line with the new Medium-Term Management Plan (2022‐2024) announced in February 2022, Yamaha Motor is strengthening its efforts for sustainability, seeking to contribute to creating a more sustainable world. Going forward, to accelerate the carbon offsetting initiatives necessary for achieving its goals, the Company will continue promoting the research and development of technologies that contribute to sustainability.

*1: Based on Yamaha Motor and Nippon Paper Industries Co., Ltd. research

*2: Some models are not using this part.

■Contact us from the Press

Corporate Communication Division, PR group: +81-538-32-1145

■News Center: https://global.yamaha-motor.com/news/

The CNF reinforced resin part being mass-produced is the engine cover*² for power units and was developed in collaboration with Nippon Paper Industries Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo). Yamaha Motor is also examining the greater use of various cellulose fibers not only in marine products but also in motorcycles and a wide range of other Yamaha products in the future.

CNF reinforced resin is a new high-strength material manufactured by kneading and dispersing CNF, a biomass material made from wood resources, into resins such as polypropylene. In addition to being over 25% lighter than existing resin materials, it also has excellent material recyclability, leading to a reduction in the amount of plastics used and greenhouse gas emissions, mainly CO₂.

In line with the new Medium-Term Management Plan (2022‐2024) announced in February 2022, Yamaha Motor is strengthening its efforts for sustainability, seeking to contribute to creating a more sustainable world. Going forward, to accelerate the carbon offsetting initiatives necessary for achieving its goals, the Company will continue promoting the research and development of technologies that contribute to sustainability.

*1: Based on Yamaha Motor and Nippon Paper Industries Co., Ltd. research

*2: Some models are not using this part.

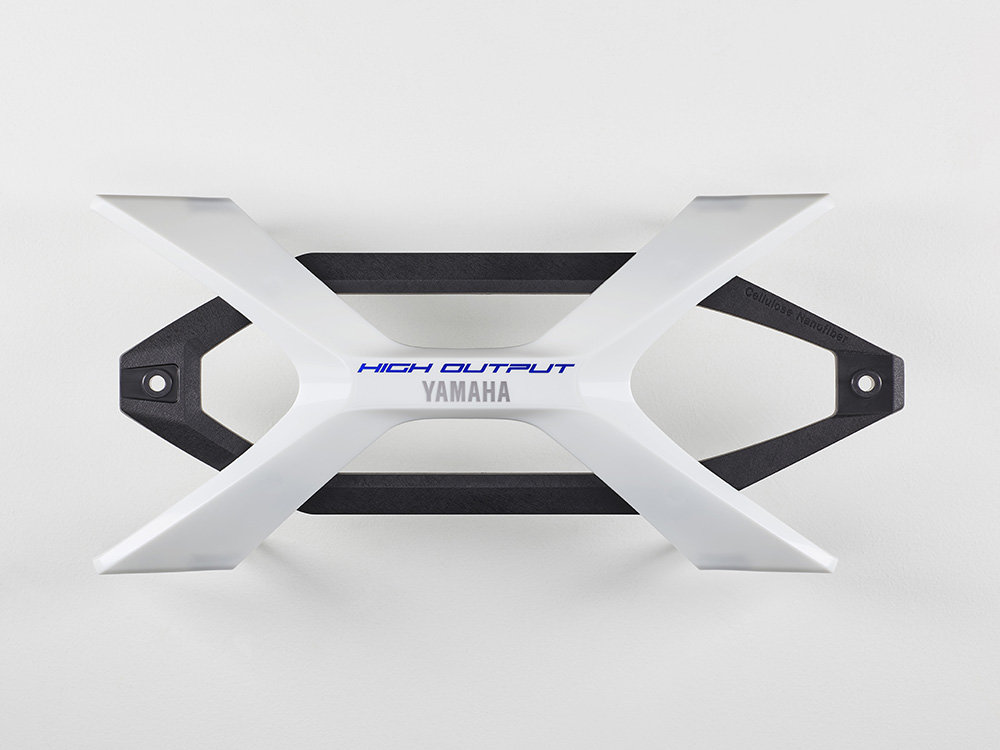

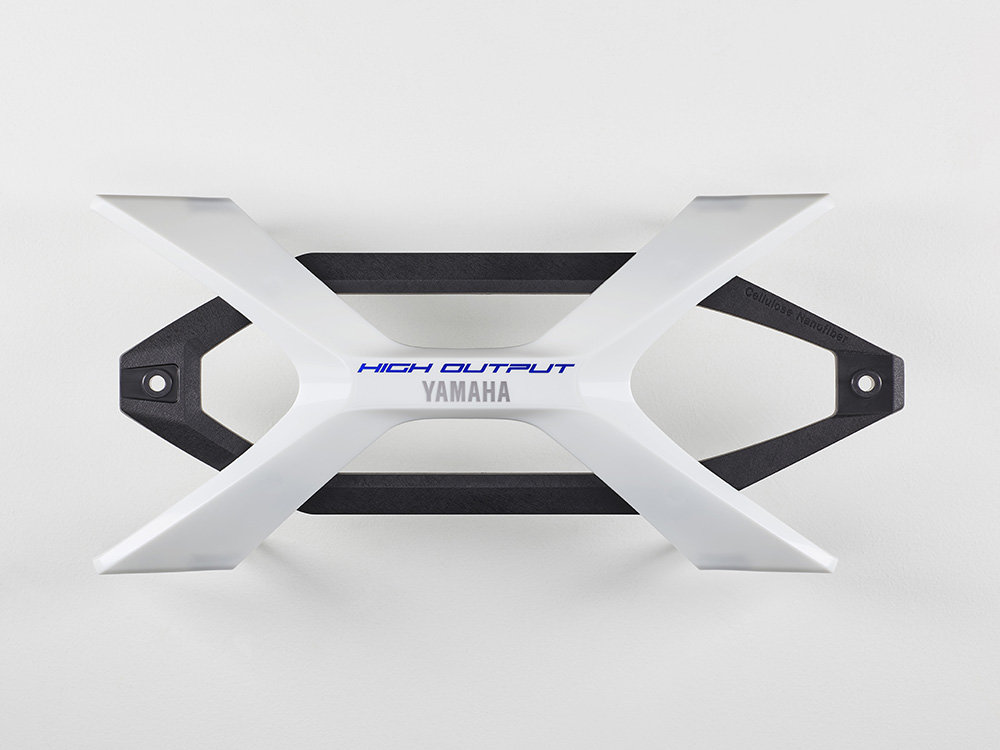

New engine cover made of CNF reinforced resin

Cellulose nanofiber reinforced resin Cellenpia Plas(R)

■ New Engine Cover Features

・ Anticipating use in the harsh environment of seawater and heat, achieves strength and other material properties equal to or greater than existing materials

・ Over 25% lighter than existing materials. In addition, the new design cuts waste further by reducing the amount of resin used while contributing to overall weight reduction

・ The material is highly recyclable and can be used repeatedly to reduce the amount of plastic used, leading to reductions in greenhouse gas emissions

・ The design of the current engine cover has been renewed, expressing not only strength but also innovation and environmental considerations. Reminiscent of a strut tower bar, this crossbar concept has a layout that shows the engine in a more dynamic as well as attractive manner

・ Anticipating use in the harsh environment of seawater and heat, achieves strength and other material properties equal to or greater than existing materials

・ Over 25% lighter than existing materials. In addition, the new design cuts waste further by reducing the amount of resin used while contributing to overall weight reduction

・ The material is highly recyclable and can be used repeatedly to reduce the amount of plastic used, leading to reductions in greenhouse gas emissions

・ The design of the current engine cover has been renewed, expressing not only strength but also innovation and environmental considerations. Reminiscent of a strut tower bar, this crossbar concept has a layout that shows the engine in a more dynamic as well as attractive manner

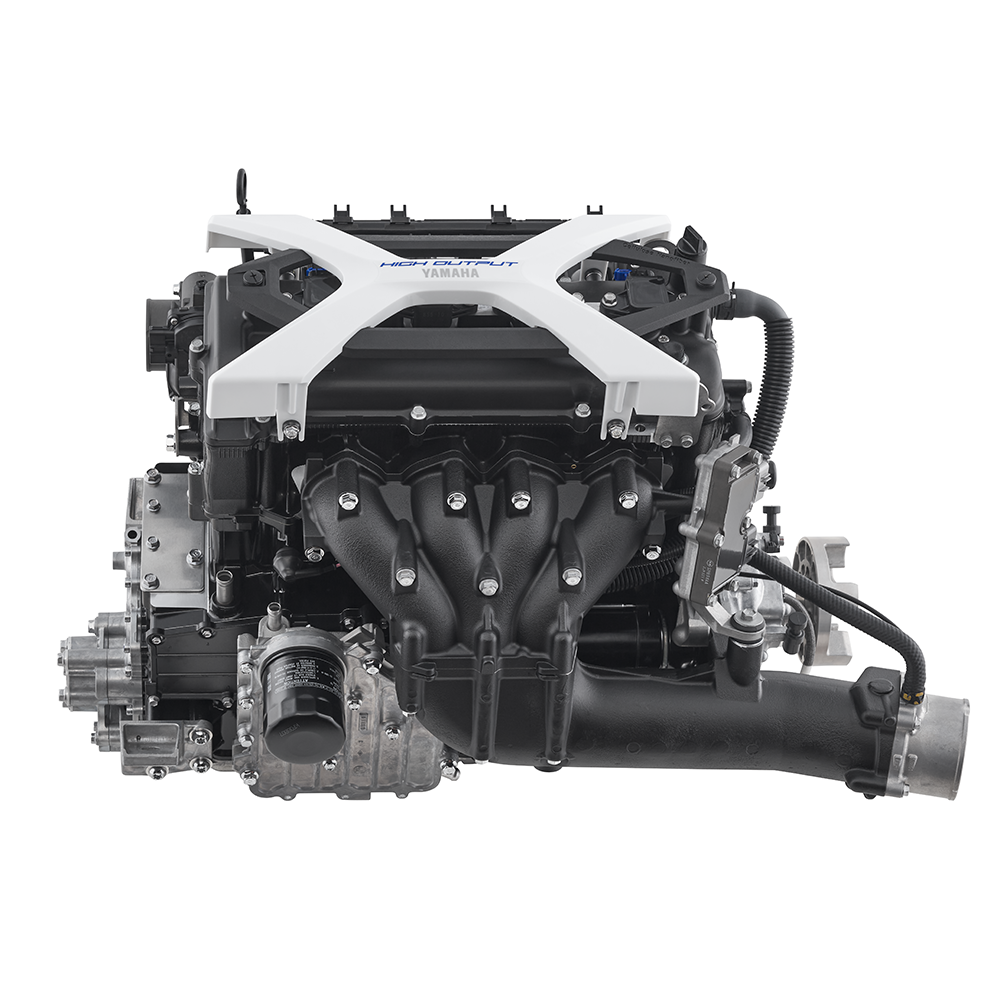

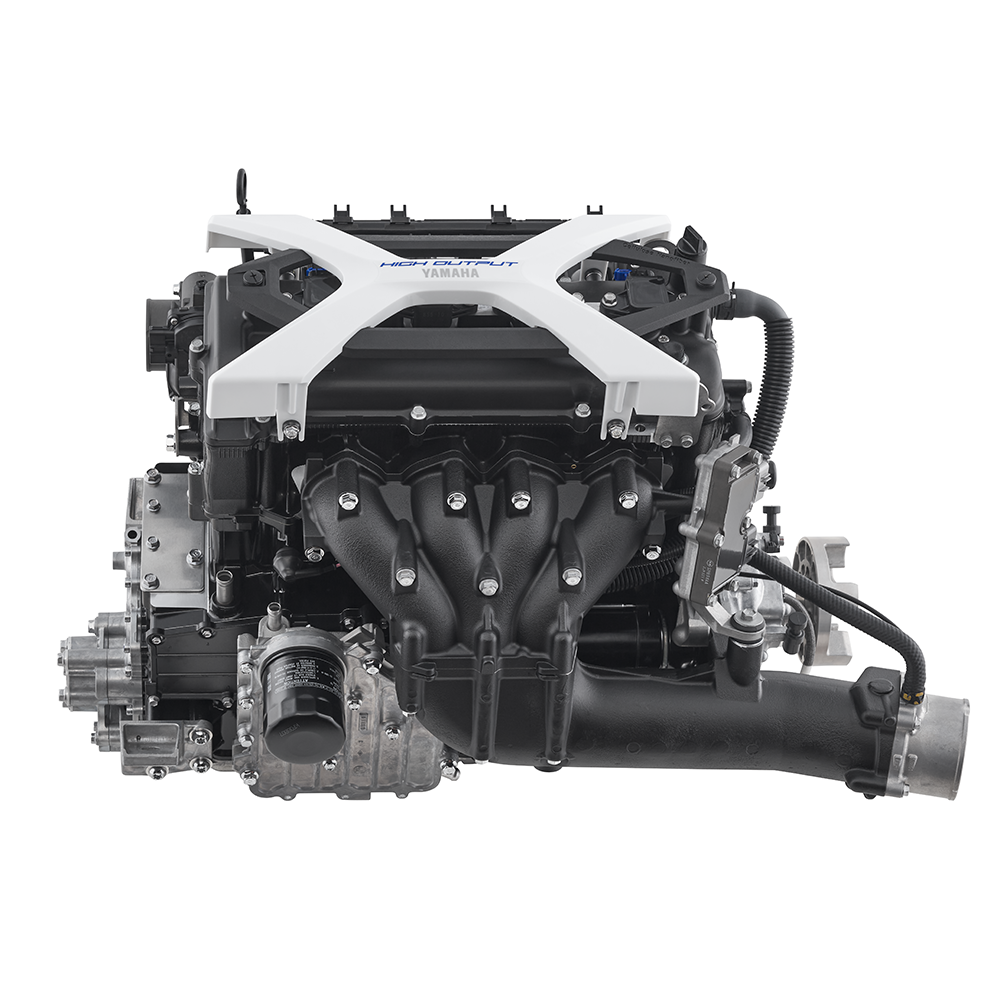

New HO engine

Reference: New naturally aspirated high-output (HO) engine

・ Yamaha's naturally aspirated high-output engine (HO engine) has been fully redesigned for the first time in 15 years. Displacement has been raised to an industry-leading 1.9L and the unit achieves the highest output for a naturally aspirated engine for water-jet propulsion

Reference: Introducing the 2024 model WaveRunner lineup

・ The lineup includes 20 models across five series: Luxury, Performance, Recreation, Rec Lite, and Freestyle

・ The all-new HO engine is employed in five models in three series: Luxury, Performance, and Recreation

Reference: Introducing the 2024 model Sports Boat lineup

・ The lineup includes 30 models across six series: 19 ft., 22 ft., 25 ft., 27 ft., Wake, and Center Console

・ The all-new HO engine is employed in 17 models in five series: 19 ft., 22 ft., 25 ft., Wake, and Center Console

・ Yamaha's naturally aspirated high-output engine (HO engine) has been fully redesigned for the first time in 15 years. Displacement has been raised to an industry-leading 1.9L and the unit achieves the highest output for a naturally aspirated engine for water-jet propulsion

Reference: Introducing the 2024 model WaveRunner lineup

・ The lineup includes 20 models across five series: Luxury, Performance, Recreation, Rec Lite, and Freestyle

・ The all-new HO engine is employed in five models in three series: Luxury, Performance, and Recreation

Reference: Introducing the 2024 model Sports Boat lineup

・ The lineup includes 30 models across six series: 19 ft., 22 ft., 25 ft., 27 ft., Wake, and Center Console

・ The all-new HO engine is employed in 17 models in five series: 19 ft., 22 ft., 25 ft., Wake, and Center Console

2024 FX Cruiser HO WaveRunner model

2024 252XE Sports Boat

■Contact us from the Press

Corporate Communication Division, PR group: +81-538-32-1145

■News Center: https://global.yamaha-motor.com/news/