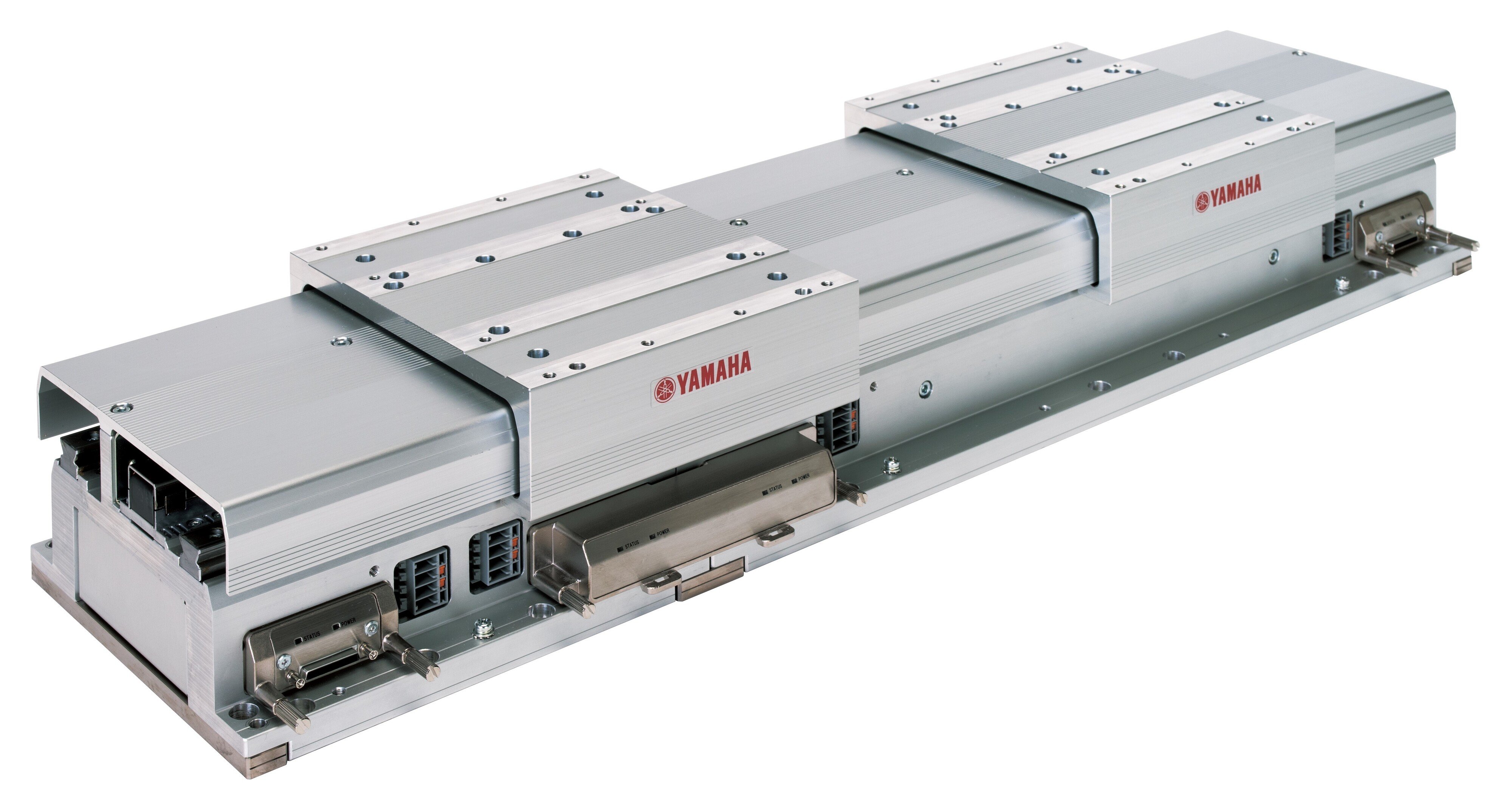

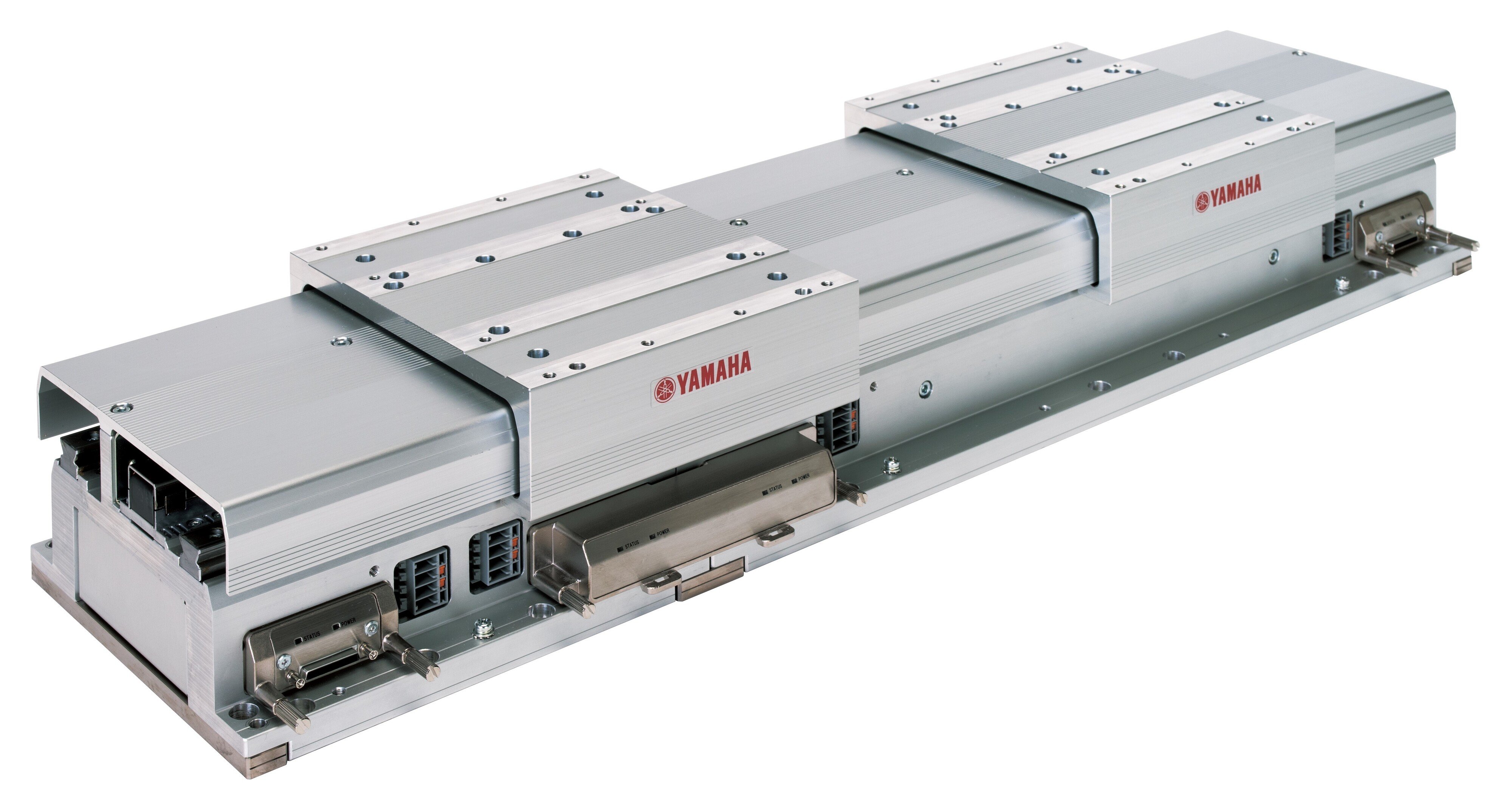

Yamaha Motor's Linear Conveyor Module LCMR200 Payload Doubles to Maximum of 30kg - Construction of a highly flexible transfer system in combination with a traversing unit -

October 3, 2022

IWATA, October 3, 2022 - Yamaha Motor Co., Ltd. (Tokyo: 7272) announced today that starting on November 1, the company has doubled the maximum payload of the LCMR200 linear conveyor module, a transfer system that features a modular structure and high-speed direct drive using linear motors, from 15kg to 30kg.

The LCMR200 is a highly efficient transfer system that achieves high productivity based on the concept of "move" over "flow". Workpieces such as products being assembled are conveyed after placement on sliders that operate independently, an operation not possible with conventional conveyors. Additionally, space efficiency on the line is greatly improved using the ability to stop with high accuracy at the assembly work position, and transfer the workpiece to the next process after assembly work.

Since commercializing the linear conveyor module for the first time in Japan in 2013, Yamaha Motor has continued to make improvements by listening to feedback from customers. While keeping the main unit as it is, this new improvement doubles the maximum payload through software updates. As a result, Yamaha Motor will be able to introduce this system not only to electrical/electronic parts productions, for which it is already widely implemented, but also to medium-sized parts productions such as in-vehicle motors for electric vehicles, PCUs (power control units), and inverters. The unit can also be utilized for food and pharmaceutical products (integrated lines including raw materials and transfer pallets). This new improvement helps to contribute to the efficiency of the transfer process in a wider range of industries than has been achieved to date.

In addition, with a combination of a traversing unit that can branch production lines and overtake processes, it is now further possible to build a greater transfer system with a higher degree of flexibility.

The unit is scheduled to be exhibited at the 25th Manufacturing World Osaka 2022 - to be held at INTEX Osaka from Wednesday, October 5th to Friday, 7th.

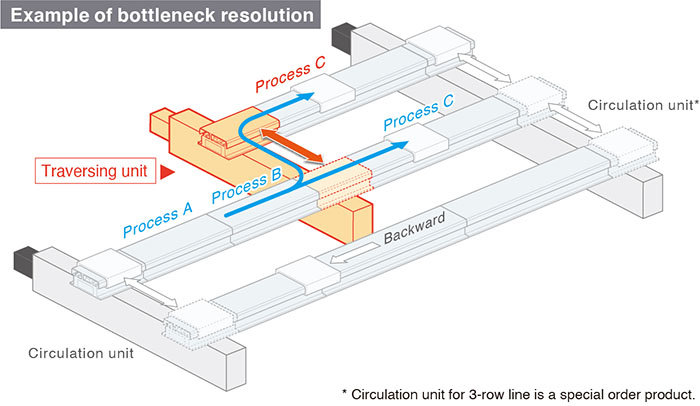

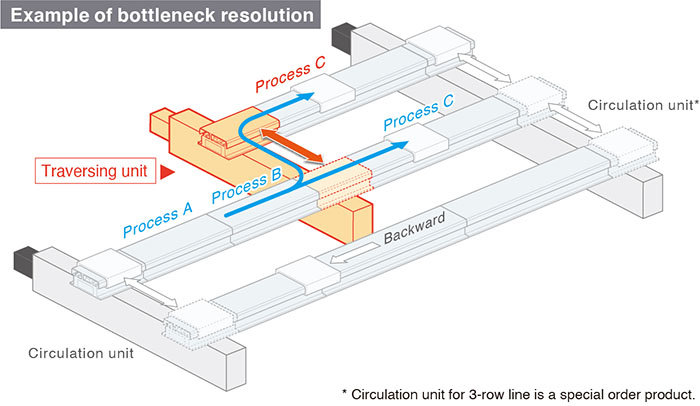

■ Traversing Unit Usage Example

When process C is on one line, if that operation becomes a bottleneck for transfer due to longer time requirements, process B can be branched with a traversing unit and process C can be made into two lines in parallel. This allows for smoother operation and leads to elimination of bottlenecks.

The LCMR200 is a highly efficient transfer system that achieves high productivity based on the concept of "move" over "flow". Workpieces such as products being assembled are conveyed after placement on sliders that operate independently, an operation not possible with conventional conveyors. Additionally, space efficiency on the line is greatly improved using the ability to stop with high accuracy at the assembly work position, and transfer the workpiece to the next process after assembly work.

Since commercializing the linear conveyor module for the first time in Japan in 2013, Yamaha Motor has continued to make improvements by listening to feedback from customers. While keeping the main unit as it is, this new improvement doubles the maximum payload through software updates. As a result, Yamaha Motor will be able to introduce this system not only to electrical/electronic parts productions, for which it is already widely implemented, but also to medium-sized parts productions such as in-vehicle motors for electric vehicles, PCUs (power control units), and inverters. The unit can also be utilized for food and pharmaceutical products (integrated lines including raw materials and transfer pallets). This new improvement helps to contribute to the efficiency of the transfer process in a wider range of industries than has been achieved to date.

In addition, with a combination of a traversing unit that can branch production lines and overtake processes, it is now further possible to build a greater transfer system with a higher degree of flexibility.

The unit is scheduled to be exhibited at the 25th Manufacturing World Osaka 2022 - to be held at INTEX Osaka from Wednesday, October 5th to Friday, 7th.

Linear Conveyor Module LCMR200

LCMR200 Product Site: https://global.yamaha-motor.com/business/robot/lineup/lcm/lcmr200/

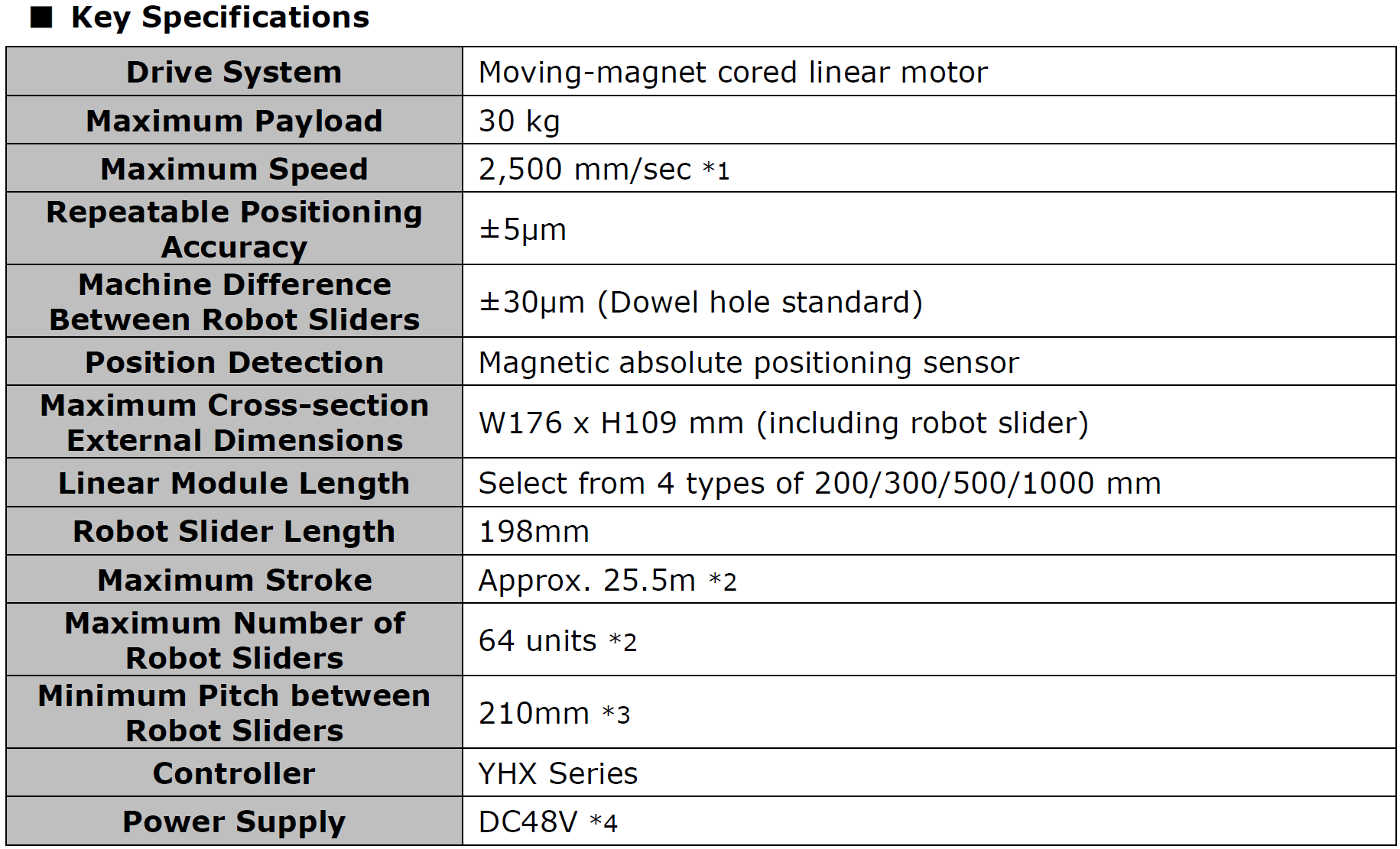

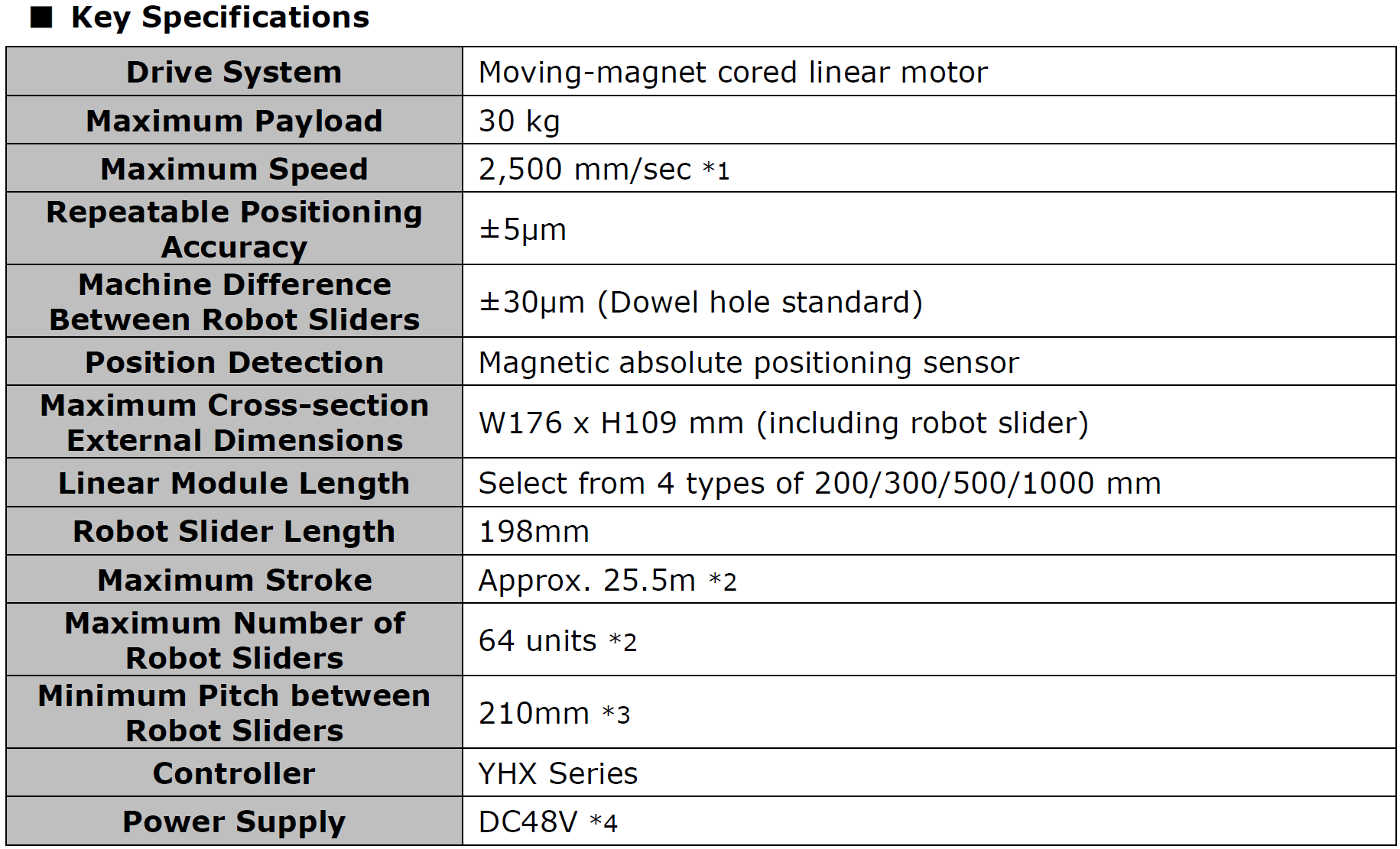

*1. If payload is over 10kg, the maximum speed may drop to 1,000mm/sec depending on the mass.

*2. Depends on system configuration.

*3. If the jig pallet mounted on the robot slider is longer, the pitch will be the jig pallet length +10mm.

*4. Requires a separate power supply unit for the YHX controller.

*2. Depends on system configuration.

*3. If the jig pallet mounted on the robot slider is longer, the pitch will be the jig pallet length +10mm.

*4. Requires a separate power supply unit for the YHX controller.

■ Traversing Unit Usage Example

When process C is on one line, if that operation becomes a bottleneck for transfer due to longer time requirements, process B can be branched with a traversing unit and process C can be made into two lines in parallel. This allows for smoother operation and leads to elimination of bottlenecks.

■Contact us from the Press

Corporate Communication Division, PR group: +81-3-5220-7211

■News Center: https://global.yamaha-motor.com/news/

Corporate Communication Division, PR group: +81-3-5220-7211

■News Center: https://global.yamaha-motor.com/news/