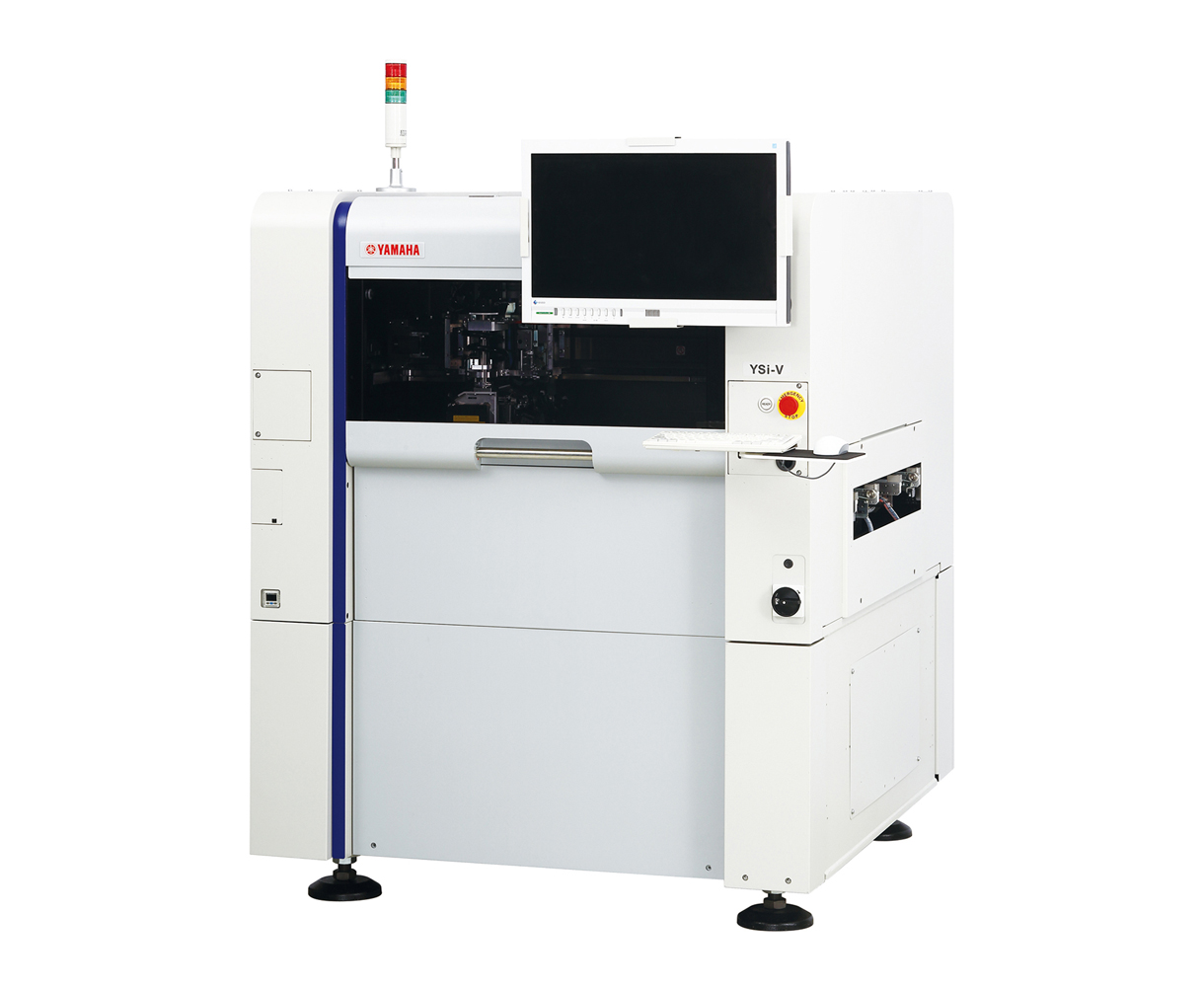

Yamaha Motor to Launch New High-end Hybrid AOI System — YSi-V 12M TypeHS2 Increases Inspection Speed and Precision,and Enhances Capacity and Performance for Specular Components —

June 1, 2017

IWATA, June 1, 2017—Yamaha Motor Co., Ltd. (Tokyo:7272) announced today that it will launch the YSi-V 12M TypeHS2 high-end hybrid automated optical inspection (AOI) system from August 1. As the successor to the YSi-V 12M TypeHS, this new very high-speed specification model features increased speed and precision, as well as enhanced specular component inspection capacity/performance.

Development of the YSi-V 12M TypeHS2 aimed for faster processing through improved image processing hardware and image inspection algorithms, and has achieved a more than a 20%*1 increase in three-dimensional inspection speed compared to the existing model. In particular, the new model delivers a significant speed increase of approximately 40% compared to the existing model in printed circuit boards (PCBs) with many component mounting points.

New features include a high-precision mode, enabling capture of clear three-dimensional images. The high-precision 7 μm resolution type includes an all-new-design dedicated three-dimensional image capture projector optical system, significantly improving form reproducibility of extremely small-sized components down to 0201 (0.25 x 0.125mm), and increasing height measurement repeatability.

Furthermore, the optimization of image capture parameters and the employment of newly-developed algorithms has enabled inspection capacity/performance compatible with thin, highly-integrated WLCSP and FOWLP*2 components, whose use on the market has risen dramatically since last year.

The YSi-V 12M TypeHS2 will be showcased at JISSO PROTEC 2017, an electronics manufacturing and mounting technology exhibition to be held from June 7 at the Tokyo Big Sight (Ariake, Koto-ku, Tokyo).

*1: Inspection time for one field of vision. Compared with the existing YSi-V 12M TypeHS model in standard mode in three-dimensional full-surface foreign matter inspection

*2: WLCSP = Wafer Level Chip Size Package FOWLP = Fan Out Wafer Level Package

| Model | Launch Date | Target Sales |

|---|---|---|

| YSi-V 12M TypeHS2 | August 1, 2017 | 200 units |

Market Background and Product Outline

Given that electronic component mounting reliability has a direct impact on the market value of final products, in the field of electronic component mounting where the trend to smaller models, higher density, higher functionality, and diversification is increasingly accelerating in recent years, in order to ensure the reliability of PCBs, fast yet accurate and precise mounting quality inspections of all items via automatic inspection are sought after. In particular, from around 2016 the usage of thin and extremely small-sized WLCSP and FOWLP which have specular gloss on the package surface increased significantly in the market, and so in addition to further increases in inspection speed, the requirements for compatibility with extremely small-sized, high-density mounting and specular components are increasing.

In order to rapidly respond to such changes and requirements in the market, the new YSi-V 12M TypeHS2 (12μ/7μ) AOI system delivers accurate inspection of extremely small-sized components such as 0201 as well as thin components with specular gloss. At the same time, it enables faster and higher-precision inspection, and significantly higher capacity/performance for in-line inspections of all items.

Main Features of the YSi-V 12M TypeHS2 Compared to Existing Models

Faster Three-dimensional Inspection Speed

The existing YSi-V 12M already included a high-speed projector for four-directional simultaneous measurement of the heights of components across the entire field of vision. Through further speed increase in the image processing hardware and image inspection algorithms, the TypeHS2 has accelerated the conversion of captured images into three-dimensional data, and therefore achieves an average inspection speed increase of more than 20% compared to the existing model. In particular, the new model delivers a proportionally-higher speed increase the more component mounting points there are on a PCB.

Improved Inspection Capacity/performance for Extremely Small-sized Components Including 0201

New features include a high-detail mode, enabling capture of clear three-dimensional images. The high-detail 7 μm type includes a revamped three-dimensional image capture projector optical system, significantly improving form reproducibility of extremely small-sized components down to 0201 (0.25 x 0.125mm) etc., and increasing height measurement repeatability.

Increased Specular Component Inspection Performance

The optimization of image capture parameters and the employment of newly-developed algorithms has enabled high inspection capacity/performance with components which have specular gloss on the package surface such as WLCSP and FOWLP as well.

YSi-V Basic Specifications

| Model | YSi-V | |||||

|---|---|---|---|---|---|---|

| Type | 12M TypeHS2 (Newly-Launched) | 12M TypeS | 12M TypeDF | 5 M | ||

| Resolution | 12μm | 7μm | 12μm | 7μm | 12μm | 18μm |

| Camera Pixel Nos. | 12 Million Pixels | 5 Million Pixels | ||||

| Applicable PCB Dimensions | L610 x W560mm (Max) to L50 x W50mm (Min) (in single-lane spec.) *L750 mm long type PCB compatible (option) |

|||||

| Inspection Lighting | Visible light (Red/Green/Blue) and Infra-Red | |||||

| Inspection Items | Status of components immediately after mounting | |||||

| Status of components and soldering after hardening | ||||||

| Power Supply | 3-phase AC 200/208/220/230/240/400/416 V ± 10% 50/60 Hz | |||||

| Air Supply | 0.4 MPa or more, clean and dry state | |||||

| External Dimensions | L1,252 x W1,497 x H1,550mm (excluding projecting parts) | |||||

| Weight | Approx. 1,300 kg | |||||