Analysis

Leveraging our accumulated expertise with the latest analytical technology allows us to go beyond simple checks and offer more efficient and effective proposals.

Our Wealth of Expertise is Our Strength

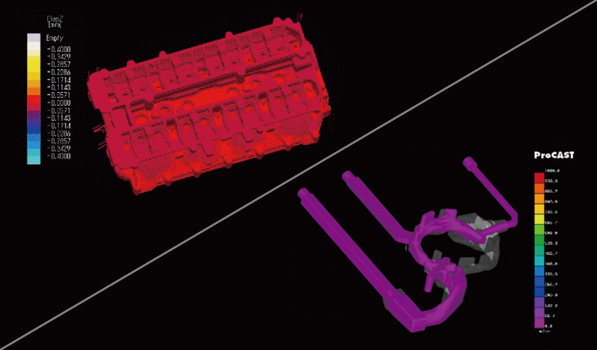

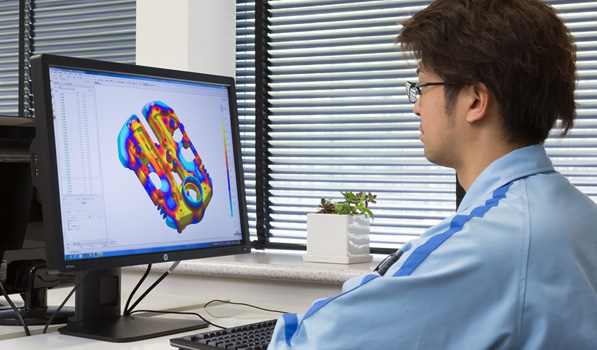

We perform metalworking analysis using state-of-the-art computer-aided engineering (CAE) software and the latest technologies. However, castings are like living things. It is incredibly difficult to simulate on a computer the entirety of the increasingly precise casting methods used in factories today to create thin-walled, lightweight parts. This is where Yamaha's accumulated experience and know-how from years of trials and testing become invaluable. By combining the latest analysis technology with our wide-ranging expertise, we are able to offer clients ideal metalworking solutions.

From Verification to Proposals

After producing a prototype or product, we subject it to in-depth analysis to verify that it clears all the design requirements. While this is a fundamental principle of our work, it is still only one part of our criteria. By getting involved from the initial phases of a product's engineering and design, we are able to make more efficient proposals to our clients that reduce development time, the number of parts and—ultimately—costs. Our aim is to devise dependable and on-target proposals that exceed the expectations of the designers.

Bridging the Gap between Design and Manufacturing

The manufacturing of motorcycles requires highly sophisticated casting technologies. To improve a motorcycle's overall performance, Yamaha casts parts that are not only lightweight and thin-walled, but also single pieces whenever possible in order to reduce the number of components needed. In addition, many cast motorcycle components also function as important exterior styling elements, thus they require complex curved shapes for design appeal and a high-quality appearance. Regardless of the degree of difficulty, an essential part of our analysis work is to meet the designers' requirements and to then exceed their expectations with our manufacturing.

Speed and Quality at Low Cost

One outcome of manufacturing motorcycles and many other products is our style of small-batch production of a diverse set of items. Since rapid development speed is pivotal to achieving this, Yamaha created a sophisticated system that quickly analyzes data and promptly derives the ideal shape within the parameters specified by the designers. The result is high-quality, high-precision support for your production needs at a low cost.

Our Business

We apologize for any inconvenience caused and we are hoping for your kind consideration.