Outboard Engines Weight Reduction

A linerless cylinder solution aimed at weight reduction in high-horsepower outboard engines

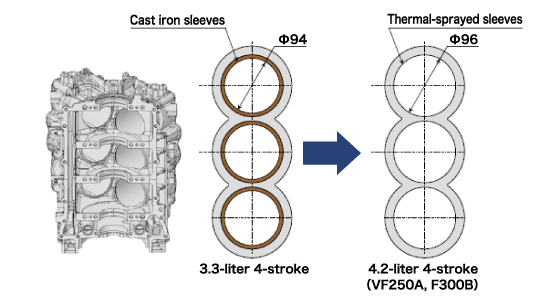

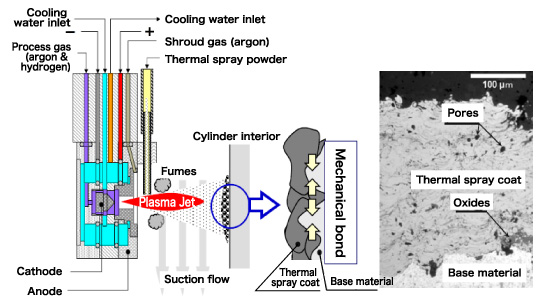

Aiming to reduce engine weight, this solution successfully eliminated the need for cast iron sleeves lining the cylinder walls. A plasma spray gun is used to line the inner walls of the cylinders with an extremely high temperature alloy that forms an extremely thin but strong cylinder lining—a thermal-sprayed coating. This process was made possible through the combined use of advanced technologies and techniques, including improving the quality of the cast aluminum piece itself and surface pretreatment for the spraying. Eliminating the need for cylinder sleeves enabled a higher displacement without changing bore pitch and this also contributed to higher engine output.

Need

- Eliminate cylinder sleeves with the goal of reducing weight with high-horsepower outboard engines

DevelopmentDirection #1

- Employ a thermal-sprayed liner for the cylinder walls

DevelopmentDirection #2

- Use high-quality die casting to enable the use of a plasma spray coating

Solution

01Die-Casting Technologies

Improved cylinder wall quality and higher quality overall via fine control of the molding and machining processes

02Plasma Spraying Technologies

Thermal spray coating technology was used to apply a robust and even coating on the cylinder walls and aided in achieving consistent production.

Result

- 01Successful production of the first outboard engine with linerless thermal-sprayed cylinders

- 02Engine displacement increased from 3.3 L to 4.2 L without changing the bore pitch

- 03Recorded a cumulative production of 220,000 units (2010-2021)

We apologize for any inconvenience caused and we are hoping for your kind consideration.