Lightweight, High-Rigidity Aluminum Wheels for Motorcycles

A solution combining high-precision casting and flow forming

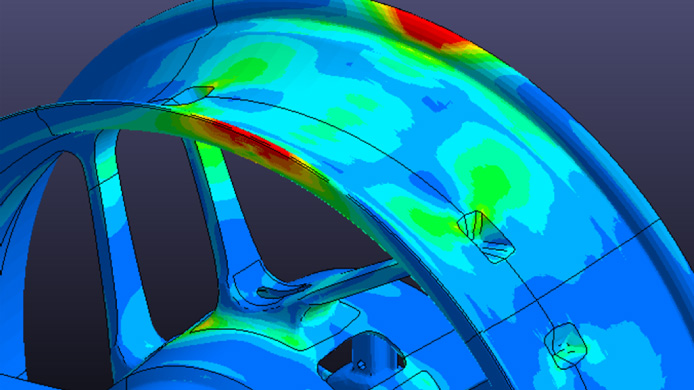

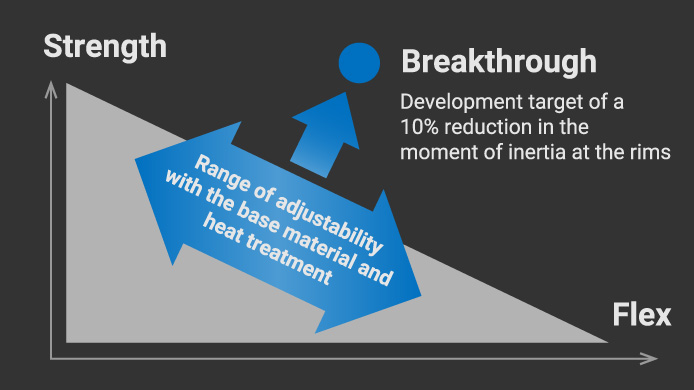

The wheels of a motorcycle are critical factors in determining its handling performance. The lighter the wheels are, the greater the handling stability and overall performance. However, at the same time they need a high level of rigidity to withstand the forces they are subjected to as well as the toughness for lasting durability. Achieving these qualities would not only require a carefully selected aluminum alloy but also combining high-precision casting with flow forming methods. Yamaha boasts a stock of advanced casting technologies and techniques acquired through long years of casting parts such as motorcycle wheels and frames. These were put to use to successfully develop new aluminum wheels that are lightweight, strong, and have the right amount of flex.

Need

- Manufacture lightweight, high-rigidity aluminum wheels for motorcycles

DevelopmentDirection #1

- Tune the wheel design for the optimum balance of strength and toughness

DevelopmentDirection #2

- Apply our knowledge and techniques for creating hollow parts and weight reduction garnered over the years

DevelopmentDirection #3

- Use flow forming to make the rim areas thinner as well as stronger

Solution

01Concurrent Engineering

Engaged in concurrent development for the wheel design, the aluminum alloy and manufacturing methods

02Material Research and Heat Treatment Techniques

Developed the aluminum alloy and manufacturing methods to achieve the right degrees of both strength and flex

03Flow Forming

Employed flow forming as a manufacturing technique

Result

- 01Achieved a combined front/rear wheel total weight reduction of 700 g

- 02Wheel rim sections made thinner from 3.0 mm to 2.0 mm

We apologize for any inconvenience caused and we are hoping for your kind consideration.