Initiatives for "Resource Recycling"

Yamaha Motor works on solution to issue of resource recycling through its business activities.

The 3R concept (Reduce, Reuse, Recycle) is becoming ever more important in all phases of product life cycles, from development and production to use and final disposal, in order to create a recycling-oriented society. The Yamaha Motor Group set “promoting recycling and the effective use of limited resources” as a goal and has undertaken various initiatives to create a circular economy.

Going forward, we will continue to adopt various approaches to conserve natural resources and enhance recycling efficiency. In addition to actively utilizing recyclable materials, we are reducing the number of parts and making them smaller by pursuing optimal size. We also use LED technologies to lengthen product life while adopting designs that facilitate dismantling and improving the recyclability of parts. Our aim is to improve the applicability of the 3R concept to our products.

Contents

- Reduction of New Resource Use through the Use of Renewable Resources

- With the use of this eco-friendly recycled PP material in motorcycles

- Yamaha Motor First to Use Green Aluminum in Japanese Motorcycles

- Yamaha Motor to Adopt Plant-Derived Next-Generation Materials for Personal Watercraft Parts- World's first practical use for vehicle parts -

- Motorcycle Recycling System

- Recycling System for Small FRP Boats

- FRP Pool—Renewal

- FRP Pool—Reduce

- FRP Pool—Reuse

- FRP Pool—Recycle

- Measures to Reduce Waste and Conserve Resources at the Manufacturing Stage

- Measuring and Reducing Water Consumption

Reduction of New Resource Use through the Use of Renewable Resources

3R Designs and Product Recycling

The Yamaha Motor Group is proactively incorporating the "3R (Reduce, Reuse, Recycle) design" in its various products. In Japan, we continue to work with other companies in our industry in the "motorcycle recycling system" for appropriate disposal by stores handling motorcycle scrapping. We also participate in a similar "recycling system for small FRP boats" in the marine segment, and are also implementing "renewal, reduce, reuse, recycle" initiatives for FRP pools.

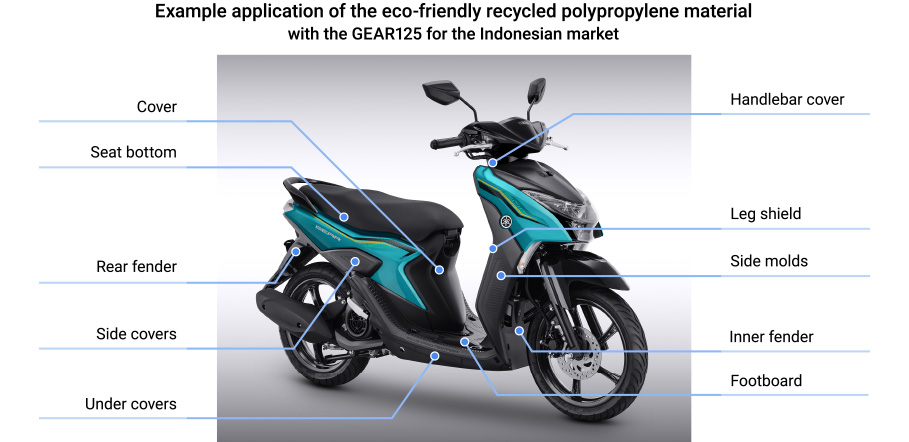

With the use of this eco-friendly recycled PP material in motorcycles

Yamaha Motor Co., Ltd. has succeeded in developing a high-quality and environmentally friendly recycled polypropylene (PP) material which can be used for the main exterior bodywork for motorcycles. The Company will begin using the new raw material with the main 2023 commuter models for ASEAN markets.

With the use of this eco-friendly recycled PP going forward, the Company plans to raise the usage ratio of such recycled materials in motorcycles and gradually adopting the material in other product categories as well.

Yamaha Motor First to Use Green Aluminum in Japanese Motorcycles

Yamaha Motor Co., Ltd. announced today that it has reached an agreement with an aluminum ingot supplier for the procurement of green aluminum, and began using it as a raw material for parts in Yamaha motorcycles in February 2023. This is the first time*1 for green aluminum to be used in Japanese motorcycles and the Company plans to gradually expand its usage in models going forward.

"Green aluminum" is aluminum that is refined using renewable energy sources to emit less CO2 in its manufacture. Aluminum parts account for 12% to 31%*2 of the total vehicle weight of a motorcycle, so adopting green aluminum is one effective approach for reducing CO2 emissions from the raw material manufacturing part of a product's life cycle (falls under Scope 3 Category 1 emissions for supply chains).

Through the development of its engineering and production technologies and expertise, Yamaha Motor has actively pushed the use of recycled aluminum, which now comprises some 80%*3 of the Company's aluminum usage. This introduction of green aluminum is meant to complement this and will be employed for parts that still cannot be manufactured with recycled materials. As a first step, Yamaha Motor will utilize green aluminum for certain parts in its large-displacement and off-road competition motorcycles, and the Company plans to expand the number of models using the material in the future as available supply volumes allow.

※1 According to Yamaha Motor research

※2 According to Yamaha Motor research in 2022

※3 Calculated based on the amount of raw material used in 2022 at principal Yamaha Motor factories in Japan and overseas

Yamaha Motor to Adopt Plant-Derived Next-Generation Materials for Personal Watercraft Parts- World's first practical use for vehicle parts -

Yamaha Motor Co., Ltd. announced today that it will adopt plant-derived cellulose nanofiber (CNF) reinforced resin for marine products as an initiative toward reducing CO2 emissions and the Company's environmental footprint. In developing the material, Yamaha Motor has reached a collaborative agreement with Nippon Paper Industries Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo). This is the world's first* practical use for vehicle parts.

The parts developed using this material will be used in engines for personal watercraft and sport boats, and are planned to be installed in certain 2024 models. Yamaha Motor is examining the utilization of this material not only in marine products but also in motorcycles and a wide range of other products in the future.

*Based on Yamaha Motor research and Nippon Paper Industries Co., Ltd.

Cellenpia Plas®

Project for producing apparel using sustainable materials

We have received the blessings of the earth, live on this planet, and enjoy our lives. Preserving this environment for the next generation is our obligation as those enjoying the present age. What we can do now is to reduce the amount of waste that cannot be returned to nature to the barest minimum. We will tackle environmental issues by starting with whatever we can do, no matter how small.

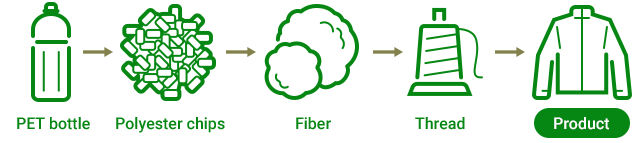

We turn used PET bottles into polyester fibers, which are reused as new products.

Product with a lower environmental impact, made from recycled and reused material.

Mesh jacket

Polo shirt

Racing t-shirt

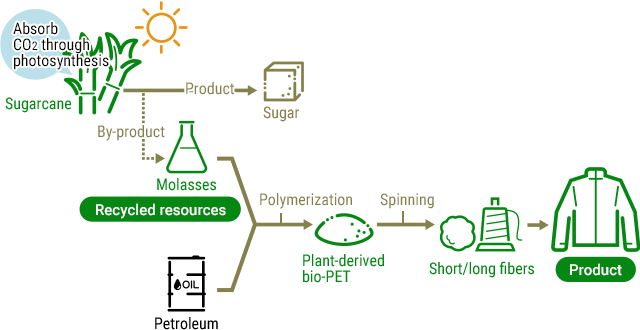

Since plants absorb CO2 from the atmosphere through photosynthesis as they grow, the overall emission of CO2 can be reduced compared to using only regular chemical fibers made from petroleum.

Environmentally-conscious products that replace chemical fibers with biomass-derived fibers.

Street cap*uses 18% biomass fiber

Racing pit shirt*uses 18% biomass fiber

* Figure and photo taken from Y'SGEAR website. (Only Japanese virsion)

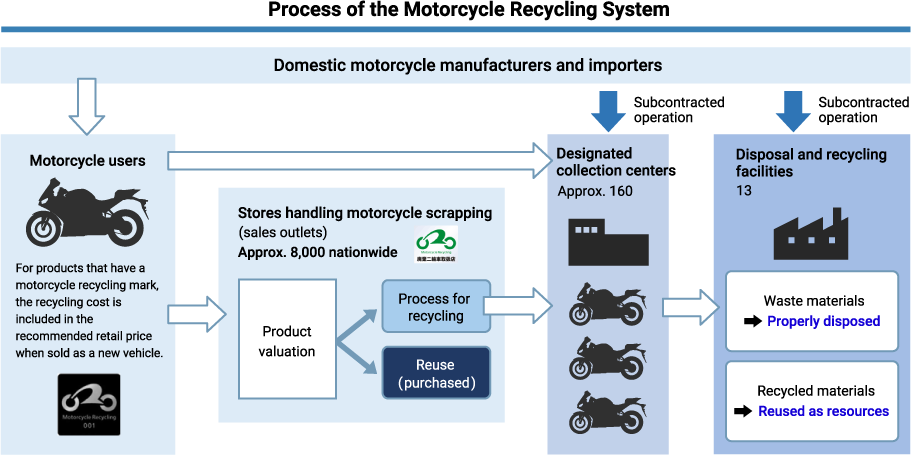

Motorcycle Recycling System

The motorcycle recycling system in Japan is a voluntary initiative to promote the appropriate disposal of scrapped motorcycles and the recycling and reuse of resources and to achieve a recycling-oriented society. In 2021, Our recycling rate was 97.9%. Along with promoting the use of the motorcycle recycling system, the Yamaha Motor Group takes responsibility for the appropriate disposal and recycling of Yamaha end-of-life motorcycles that customers wish to scrap.

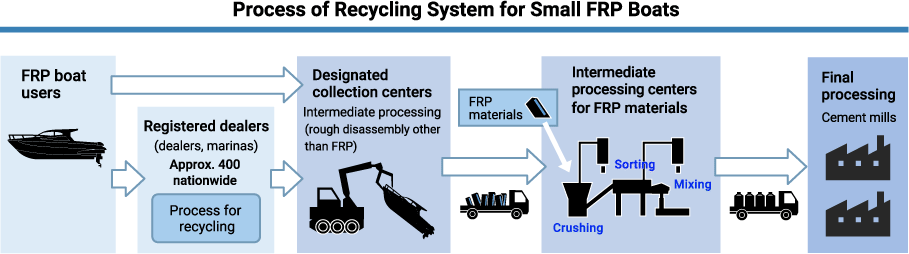

Recycling System for Small FRP Boats

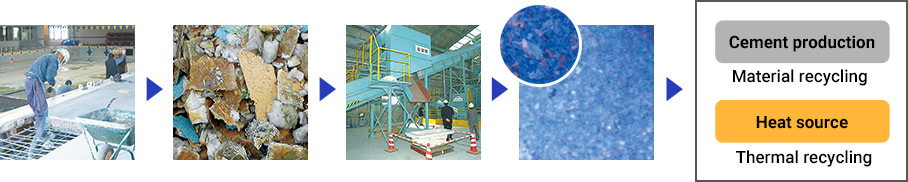

The recycling system for small boats (boats, yachts, personal watercraft, fishing boats, etc.) made from glass fiber-reinforced plastic (FRP) is mainly carried out by the Japan Marine Industry Association's FRP Boat Recycling Center. After scrapped FRP boats are taken to subcontracted, designated collection centers and roughly disassembled, FRP materials are taken to an intermediate processing center where they are crushed and sorted, and finally calcined to cement for recycling (material thermal recycling).

Yamaha Motor participates in this recycling system, and takes responsibility for appropriately disposing of and recycling FRP boats that customers wish to scrap and have recycled.

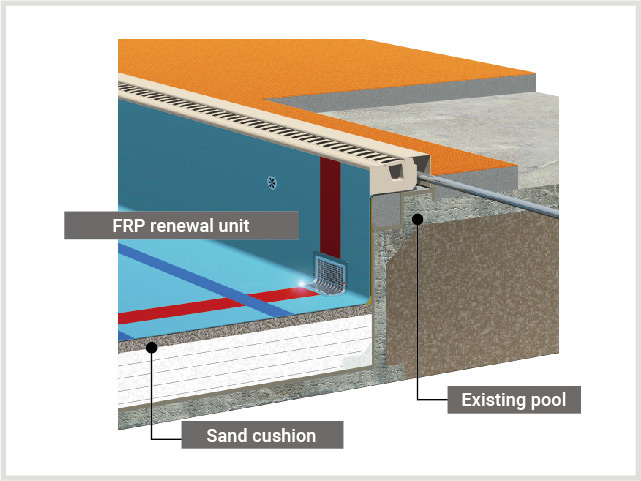

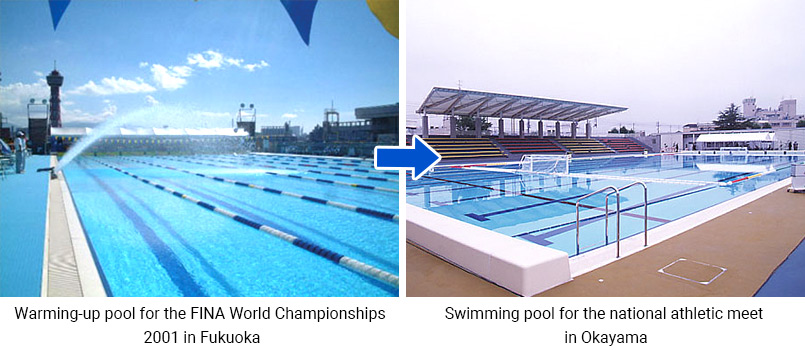

FRP Pool—Renewal

Yamaha Motor contributes to the realization of a recycling-oriented society by developing technology for creating environmentally friendly pools that leverage the merits of FRP materials. Yamaha Motor's renewal construction method makes the most of the structures of existing concrete pools, and therefore it minimizes the crushing noise generated by vibration drills and operating noise of large heavy machinery during disassembly. Moreover, while disassembling concrete pools normally produces about 350 tons of waste materials, this method requires only partial removal of the existing structure, reducing the amount of waste materials by approximately 85%. Compared with typical reconstruction and renewal work, it significantly reduces environmental burden.

Full renewal construction method

This is a basic construction method that makes the most of an existing concrete pool in renewing it as an FRP pool.

The original concrete pool is covered with an FRP renewal unit that is secured with special stays. A layer of sand filled underneath the FRP floor panel serves as a cushion to reduce impact.

Full renewal using this method is completed in approximately 45 days, much shorter than the average construction period required to build a new pool.

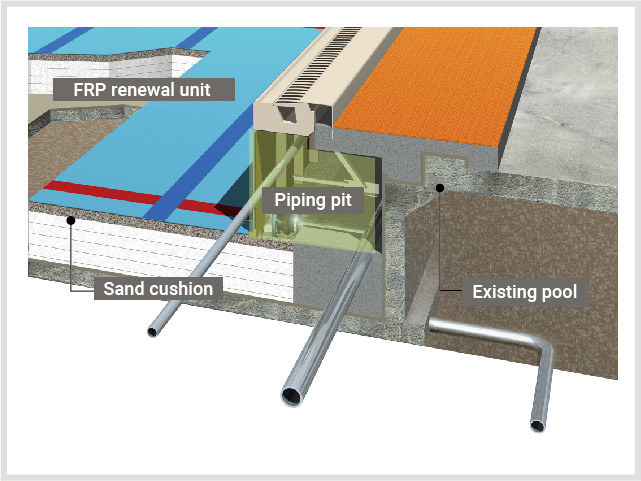

Pit renewal construction method

Old concrete pools often have buried pipes, which require a considerable amount of time and effort to deal with any pipe problems. With the pit renewal construction method, new piping pits are installed between the existing concrete pool and the FRP unit. This ensures the new pool can be maintained more easily with minimal costs.

FRP Pool—Reduce

In a recycling-oriented society, reducing waste is the top priority. FRP pools boast excellent corrosion and earthquake resistance and a long service life, enabling them to be used over an extended period of time by providing regular maintenance. The first school pool delivered more than 40 years ago in 1978 is still safely used today.

FRP Pool—Reuse

Yamaha Motor's FRP reuse construction method employs a unique modular construction that enables the pools to be disassembled and relocated for reuse.

FRP Pool—Recycle

FRP materials can be recycled in various ways, such as melting them so that they can be reused as resources and heat recovery (power generation). Now, they can also be recycled to be used as materials and a thermal energy source for making Portland cement. With these methods, FRP can be recycled at a rate of almost 100%.

Measures to Reduce Waste and Conserve Resources at the Manufacturing Stage

Yamaha Motor separates metal, plastic, foundry sand, and other waste for recycling as raw materials. We also subject oil and some plastics to a thermal recycling process to create materials that can be used as combustion improvers. In addition, we use post-combustion residue as a raw material in cement and roadbeds. As a result, we have maintained our direct and indirect landfill record of “zero tons” (a 100% recycling rate). In 2022, Yamaha Motor generated 14,173 tons of waste. It also generated 1,380 tons of industrial waste from plastic-using products.

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Waste Generated | 14,809 | 14,926 | 11,319 | 13,516 | 14,173 |

| Emissions※1 | 21,895 | 19,798 | 15,275 | 21,520 | 24,282 |

| Specially controlled industrial waste※2 | 229 | 288 | 122 | 178 | 198 |

*1 Aggregate volume of materials discharged (including industrial waste, specially controlled industrial waste and materials with value)

*2 Industrial waste materials that are explosive, poisonous, infectious, or otherwise harmful or potentially harmful to human health or the environment

The Yamaha Motor Group has been working to reduce its volumes of waste by thoroughly separating waste, introducing returnable packing materials, and using longer-lasting cutting fluids and oils. The Yamaha Motor Group generated 64,224 tonsExternal Assurance of waste in 2022 (138 companies within the scope of global environmental consolidation).

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| a) Recycled/reused waste | 35,263 | 35,862 | 26,539 | 32,693 | 46,328 |

| b) Waste disposed of (total of the following breakdown) | 16,659 | 15,466 | 14,146 | 16,864 | 17,897 |

| - Waste disposed of by landfill | 6,953 | 6,919 | 6,827 | 8,666 | 10,496 |

| - Waste disposed of through incineration with energy recovery | 0 | 0 | 0 | 0 | 0 |

| - Waste disposed of through incineration without energy recovery | 0 | 0 | 0 | 0 | 0 |

| - Waste disposed of by other methods | 0 | 0 | 0 | 0 | 0 |

| - Waste disposed of through unclear methods | 9,706 | 8,547 | 7,319 | 8,199 | 7,401 |

| Data coverage rate of environmental consolidation companies (%) | 83 | 96 | 100 | 100 (134 companies) |

100 (138 companies) |

| Total waste generated (a+b) | 51,922 | 51,328 | 40,685 | 49,557 | 64,224External Assurance |

Measuring and Reducing Water Consumption

The Yamaha Motor Group is working to reduce consumption of water. In accordance with our 2050 goal of "reducing water usage in production activities," we continue to strive to measure our global use of water and reduce consumption Groupwide through programs including the reuse of coolant water and water collection (rainwater and other sources) at factories, the reuse of water using reverse osmosis (RO) membranes, posters to remind employees to conserve water, and the installation of water-saving packing in faucets.

In 2022, Yamaha Motor's water intake volume was 1,177 thousand m3 and wastewater volume was 1,211 thousand m3External Assurance.

Boundary: 138 companies within the scope of global environmental consolidation

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

| Underground water | 1,501 | 1,723 | 1,472 | 1,615 | 1,576 |

| Industrial water | 1,448 | 934 | 731 | 859 | 946 |

| Tap water | 946 | 1,251 | 1,002 | 1,226 | 1,228 |

| Other fresh water | 258 | 375 | 380 | 328 | 300 |

| Total water intake(fresh water) | 4,153 | 4,283 | 3,585 | 4,028 | 4,049 External Assurance |

Note: Breakdown includes estimated figures.