Yamaha Motor Launches Robonity Series Motorless Single Axis Actuators — High-Rigidity/Accuracy, Compact, Compatible with 8 Key Motor Brands —

March 20, 2019

IWATA, March 20, 2019—Yamaha Motor Co., Ltd. (Tokyo:7272) announced today that it will launch the Robonity Series1 of slider-type motorless single axis actuators on May 7, 2019. The new actuators are intended for use across a wide range of production processes, such as in automotive parts, electrical and electronic products, medicine, foodstuffs, and cosmetics, for assembly, conveyance, coating, inspection, etc. Compatibility with the products of eight key motor manufacturers2 means that customers can mount the motors and drivers to which they are accustomed. The initial launch is aimed at the Japanese domestic market, with overseas launches planned to follow.

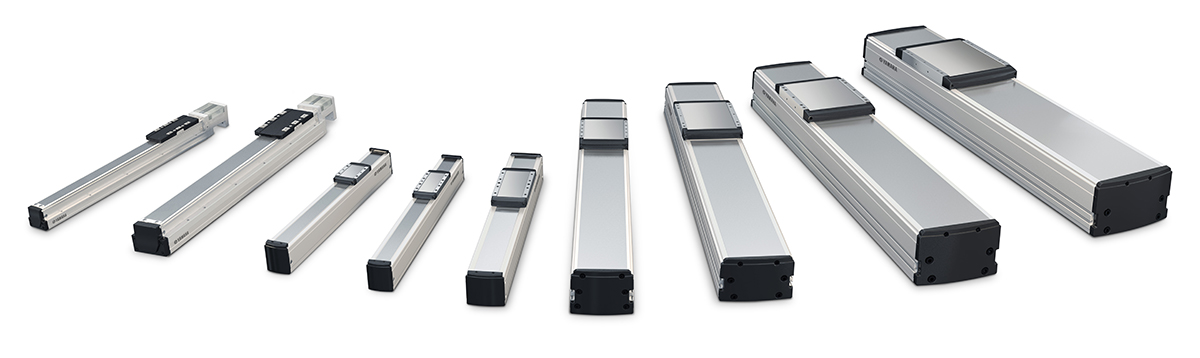

The Robonity Series lineup includes the high-rigidity, compact, and low-cost LBAS basic models as well as the high-accuracy and high-durability LGXS advanced models.

Through its newly-designed structure, in which the guide rails and frame are integrated, the LBAS basic models deliver high moment rigidity in a compact form. The LGXS advanced models feature high-efficiency and high-accuracy ground ball screws as standard, creating high-precision models which also deliver high reliability and durability. The dust-proof stainless-steel sheet on the upper surface of the unit means that compatibility with clean specifications is standard.

Yamaha Motor develops and manufactures a variety of industrial robots necessary for automated production lines, with our wide product range featuring single axis robots, SCARA robots, articulated robots, and linear conveyors. Adding motorless single axis actuators to these product groups allows Yamaha Motor to provide the optimal solution for a broader range of automation requirements.

In the future, we plan to further expand the variations of types and sizes in this series.

1. “Robonity” is a coined word that incorporates “robot” and “infinity.” The name expresses the concept of a series with a rich array of variations.

2. Basic models. The Advanced models are compatible with three manufacturers’ products.

| Models | Launch Date/ Target Sales |

||

|---|---|---|---|

| Robonity Series | Basic models | LBAS05, LBAS08 | May 7, 2019 6,000 units (first year from time of release, in Japan) |

| Advanced models | LGXS05, LGXS05L, LGXS07, LGXS10, LGXS12, LGXS16, LGXS20 | ||

LBAS Basic Models Main Features

1) High rigidity and high accuracy in a compact form

Thanks to the structure which integrates the guide rails and frame, this model delivers high moment rigidity (70%-200% improvement compared to previous models) and high accuracy (travel parallelism ±0.02/800mm) within compact dimensions (approximately 20% smaller than previous models).

2) Reduction in installation working hours/easy maintenance

The unit can be secured in place from the upper or lower surface without removing exterior components such as the cover. The open reference planes on the side surfaces and dowel holes on the underside make installation easy. Grease nipples have been provided on the slider side surfaces, enabling lubrication of the ball screws and guides without disassembling the product. Four directional options are available during motor installation, and conversion even after delivery is simple by using dedicated bending parts.

- Compatible motor manufacturers

Yaskawa Electric, Mitsubishi Electric, Keyence, Omron, Sanyo Denki, Tamagawa Seiki, Delta Electronics, Panasonic

LGXS Advanced Models Main Features

1) High accuracy, high rigidity, and high durability through standard fitting of ground ball screws

Features standard fitting of high-efficiency and high-accuracy ground ball screws, lead precision of Japanese Industrial Standard accuracy class C5, and repeatable positioning accuracy of ±0.005mm. In addition, yield is improved through enabling high-accuracy positioning. Reduced noise levels and longer life have also been achieved.

2) The standard fitting of a dust-proof stainless-steel sheet means that compatibility with clean specifications is also standard

The fitting of a high-durability dust-proof stainless-steel sheet as standard equipment onto the upper surface of the main unit reduces contamination by external foreign matter. Moreover, as air suction couplings (taps) are also standard equipment, usage in clean environments is possible simply by connecting piping and applying suction.

3) Motor installation direction can be easily changed using bending units

The standard specification motor orientation is straight but can be easily changed to motor bending specification (left or right).

- Compatible motor manufacturers

Yaskawa Electric, Mitsubishi Electric, Keyence

Robonity Series Basic Specifications

Basic models

| Model code | LBAS05 | LBAS08 | ||||||

|---|---|---|---|---|---|---|---|---|

| Applicable motor (W) | 100 | 200 | ||||||

| Repeatable positioning accuracy (mm)1 | ±0.01 | |||||||

| Speed reduction mechanism | Rolling ball screw φ12 (C7 class) | Rolling ball screw φ16 (C7 class) | ||||||

| Stroke (mm) | 50-800 (50 pitch) | 50-1,100 (50 pitch) | ||||||

| Maximum speed (mm/sec)2 | 1333 | 666 | 333 | 133 | 1200 | 600 | 300 | |

| Ball screw lead (mm) | 20 | 10 | 5 | 2 | 20 | 10 | 5 | |

| Maximum payload (kg)3 | Horizontal | 12 | 24 | 40 | 45 | 40 | 80 | 100 |

| Vertical | 3 | 6 | 12 | 15 | 8 | 20 | 30 | |

| Rated thrust (N)3 | 84 | 169 | 339 | 854 | 174 | 341 | 683 | |

| Main unit maximum cross-sectional form (mm) | W54×H60 | W82×H78 | ||||||

| Overall length (mm) *ST: Stroke length |

ST+220.5 | ST+278 | ||||||

| Operating temperature Humidity |

0~40℃ 35~80%RH |

|||||||

| Compatible motors | Yaskawa Electric, Mitsubishi Electric, Keyence, Omron, Sanyo Denki, Tamagawa Seiki, Delta Electronics, Panasonic |

|||||||

1: Pulsating repeatable positioning accuracy

2: Maximum speed may not be reached when the movement distance is short or under some operating conditions.

3: The rated thrust and maximum payload values shown are estimates when the installed motors are outputting their rated torque.

Advanced models

| Model code | LGXS05 | LGXS05L | LGXS07 | LGXS10 | LGXS12 | LGXS16 | LGXS20 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Applicable motor (W) | 50 | 100 | 100 | 200 | 400 | 750 | 750 | ||||||||||||||||||

| Repeatable positioning accuracy (mm)1 | ±0.005 | ||||||||||||||||||||||||

| Speed reduction mechanism | Ground ball screw φ12(C5 class) |

Ground ball screw φ12(C5 class) |

Ground ball screw φ15(C5 class) |

Ground ball screw φ15(C5 class) |

Ground ball screw φ15(C5 class) |

Ground ball screw φ20(C5 class) |

Ground ball screw φ20(C5 class) |

||||||||||||||||||

| Stroke (mm) | 50~800 (50 pitch) |

50~800 (50 pitch) |

50~1,100 (50 pitch) |

100~1,250 (50 pitch) |

100~1,250 (50 pitch) |

100~1,450 (50 pitch) |

100~1,450 (50 pitch) |

||||||||||||||||||

| Maximum speed (mm/sec)2 | 1333 | 666 | 333 | 1333 | 666 | 333 | 1800 | 1200 | 600 | 300 | 1800 | 1200 | 600 | 300 | 1800 | 1200 | 600 | 300 | 2400 | 1200 | 600 | 2400 | 1200 | 600 | |

| Ball screw lead (mm) | 20 | 10 | 5 | 20 | 10 | 5 | 30 | 20 | 10 | 5 | 30 | 20 | 10 | 5 | 30 | 20 | 10 | 5 | 40 | 20 | 10 | 40 | 20 | 10 | |

| Maximum speed (mm/sec)2 | 1333 | 666 | 333 | 1333 | 666 | 333 | 1800 | 1200 | 600 | 300 | 1800 | 1200 | 600 | 300 | 1800 | 1200 | 600 | 300 | 2400 | 1200 | 600 | 2400 | 1200 | 600 | |

| Maximum payload (kg)3 | Horizontal | 5 | 8 | 13 | 12 | 24 | 32 | 10 | 25 | 45 | 85 | 25 | 40 | 80 | 100 | 35 | 50 | 95 | 115 | 45 | 95 | 130 | 65 | 130 | 160 |

| Vertical | 2 | 4 | 8 | 3 | 6 | 12 | 2 | 4 | 8 | 16 | 4 | 8 | 20 | 30 | 8 | 15 | 25 | 45 | 12 | 28 | 55 | 15 | 35 | 65 | |

| Rated thrust (N)3 | 41 | 69 | 138 | 84 | 169 | 339 | 56 | 84 | 169 | 339 | 113 | 170 | 341 | 683 | 225 | 339 | 678 | 1360 | 320 | 640 | 1280 | 320 | 640 | 1280 | |

| Main unit maximum cross-sectional form (mm) | W48×H65 | W48×H65 | W70×H76.5 | W100×H99.5 | W125×H101 | W160×H130 | W200×H140 | ||||||||||||||||||

| Overall length (mm) *ST: Stroke length |

ST+131.5 | ST+161.5 | ST+202 | ST+175.5 | ST+211.5 | ST+242.5 | ST+288.5 | ||||||||||||||||||

| Air cleanliness class4 | ISO CLASS 3(ISO14644-1) | ||||||||||||||||||||||||

| Suction volume (Nℓ/min) air5 | 30〜100 | 30〜115 | 30〜90 | ||||||||||||||||||||||

| Operating temperature, humidity |

0〜40℃ 35〜80%RH |

||||||||||||||||||||||||

| Compatible motors | Yaskawa Electric, Mitsubishi Electric, Keyence | ||||||||||||||||||||||||

1: Pulsating repeatable positioning accuracy

2: Maximum speed may not be reached when the movement distance is short or under some operating conditions.

3: The rated thrust and maximum payload values shown are estimates when the installed motors are outputting their rated torque.

4: Please attach air suction couplings when using the product in a clean environment. The air cleanliness class indicates the cleanliness when used at 1,000mm/sec or less.

5: The suction volume required varies depending on the operating conditions and environment.