The Aluminum Casting Process and its Applications

Introducing the stories behind Yamaha Motor's technologies.

Aluminum has many benefits for manufacturing industrial products. It is lightweight, non-magnetic, conducts heat well, and has a low melting point, making it an easy metal to cast. Even if aluminum compounds are spilled while in a molten state, the metal’s low toxicity means it doesn’t damage the soil. Since the 1960s, Yamaha has utilized the method of injecting molten aluminum into metal molds at high pressure, or “High-pressure Aluminum Die-casting”, to cast various parts and components tailored for each product.

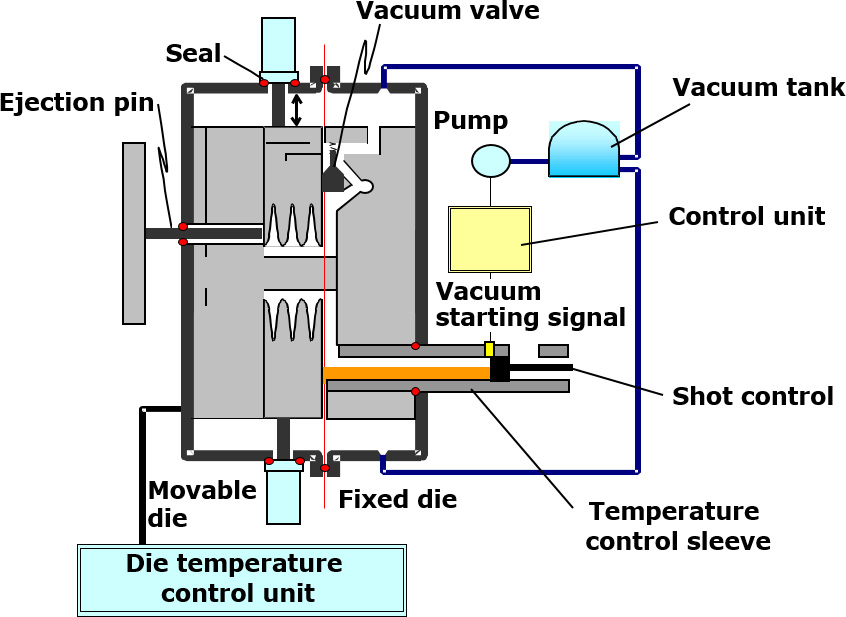

Around 1985, in order to improve the flow of the molten aluminum, Yamaha reduced the pressure inside the mold to approximately 300 millibars (approx. 4.3 psi) and practicalized a new “Low-pressure Chamber, High-pressure Injection Die-cast” process. This contributed to product benefits like weight reduction, improved vehicle mileage and noise reduction. However, simply injecting the aluminum at high pressure could sometimes result in air bubbles forming inside the cast piece. This meant that the finished item could not be made very strong, adding the hurdle of it being unfit for welding.

With the goal of developing and producing aluminum parts with greater design appeal and material quality, continuous and intensive research was conducted and resulted in the practicalization of “Controlled Filling (CF) Aluminum Die-cast Technology.” (#1) With this manufacturing process, it was possible to produce aluminum parts with smooth, flowing curves and just 1–2 millimeters thick. The first Yamaha product to feature aluminum parts produced by the process was the 2003 RX-1 snowmobile, adopting them for certain components of its chassis. The first motorcycle application was the swingarm for the YZF-R6 (#2), also in 2003. It was used again in manufacturing the main frames for the FZ6-S (#3) and FZ6-N in 2004. Since then, CF aluminum die-casting has been employed in creating chassis parts and components for various Yamaha products. More recently, the MT-09 and motorcycles based on its platform employ frames formed with CF aluminum die-casting (#4).

The idea was to find a mutual balance between the degree of vacuum, the injection speed of the molten aluminum and the temperature of the mold. First, for the pressure in the mold, the previous 300 millibars was further reduced to 20 millibars (0.2 psi) for a near-vacuum state. The injection speed of the molten aluminum was also increased. Then, a system of standards was developed and the necessary infrastructure put in place to maintain the temperature inside the mold at the optimum level to ensure that the aluminum would solidify evenly.

This comprehensive control of the overall process promoted more uniform solidification of the aluminum while also lowering the occurrence of air bubbles. This made it possible to manufacture aluminum parts with smooth, curved lines and variable thickness down to the millimeter. At the time, a similar process had already been in use for producing chassis and body parts for some European cars, the frames of flat-screen TVs and more, but Yamaha was the first to put it to practical use with motorcycles and snowmobiles.

Yamaha’s CF Aluminum Die-cast Technology is also being used for next-generation engine development. This process made it possible to cast cylinders with an aluminum alloy containing 20% silicon, something considered very difficult to achieve with conventional casting methods. The resulting cylinder has a high abrasion resistance without the need for plating or steel sleeves. Dubbed the “DiASil (Die-casting Aluminum-Silicon) Cylinder,” this all-aluminum high-performance cylinder is now used in today’s YZF-R3, YZF-R25, NMAX (#5) and many other Yamaha models.

*“CF” stands for “Controlled Filling” and refers to the control and management of the flow of aluminum into the mold.