In the production and manufacturing workplaces at Yamaha Motor, our theoretical-value-based production methodology permeates every corner. This approach classifies all Monozukuri tasks and operations as those with value and those without, and then strives to increase the ratio of those with value while raising overall production efficiency. It is a methodology for achieving breakthroughs through innovative ideas born on the factory floor. However, ever since the company’s founding, our tradition of taking seemingly illogical extra steps when creating a product remains an inseparable part of our heritage.

Where the Monozukuri Culture Flourishes

The birthplace of the Yamaha brand is in western Shizuoka Prefecture, a region with a long history as a gathering place for various businesses and industries and where a unique culture of craftsmanship developed over time.

From ancient times, the area was a center for cotton growing and this eventually created a booming textile industry using the area’s specialty cotton. This in turn led to the development and production of automated looms in the surrounding areas. From there, the technology acquired through building these looms eventually found its way into auto manufacturing.

Up in the mountains to the north lie lush forests of Tenryu cedar trees, and this sparked a forestry and lumber industry that drove subsequent advances in woodworking skills and equipment. The lumber machines originally fashioned for cutting trees then helped spur the rapid rise of Japan’s musical instrument industry. In a similar pattern, building musical instruments inevitably helped the locals hone their metalworking skills and techniques.

Blessed with a mild climate bringing a bountiful natural environment, the locals cultivated their own specialty crops and processed them into consumer products. Even the tools needed for these activities were made locally and then repurposed to give birth to other new businesses. This repeated process of innovation and spinoffs led to the unique culture of craftsmanship for which the area is now known. The driving force behind it can be summed up as the Yaramaika spirit, meaning “Let’s give it a shot!” in the local dialect. It is a major part of what led the region to become what it is today.

Roots in Musical Instruments, Weaving and Artisanry

“A musical instrument maker built a motorcycle? Does the exhaust sing do, re, mi, fa?”

Yamaha Motor Company was founded on July 1, 1955 when the motorcycle manufacturing division of Nippon Gakki Co., Ltd. (today’s Yamaha Corporation) was spun off and established as an independent enterprise. The sales personnel that shed blood, sweat and tears in their efforts to sell the YA-1, the company’s first motorcycle, are said to have endured trials aplenty at dealerships around the country.

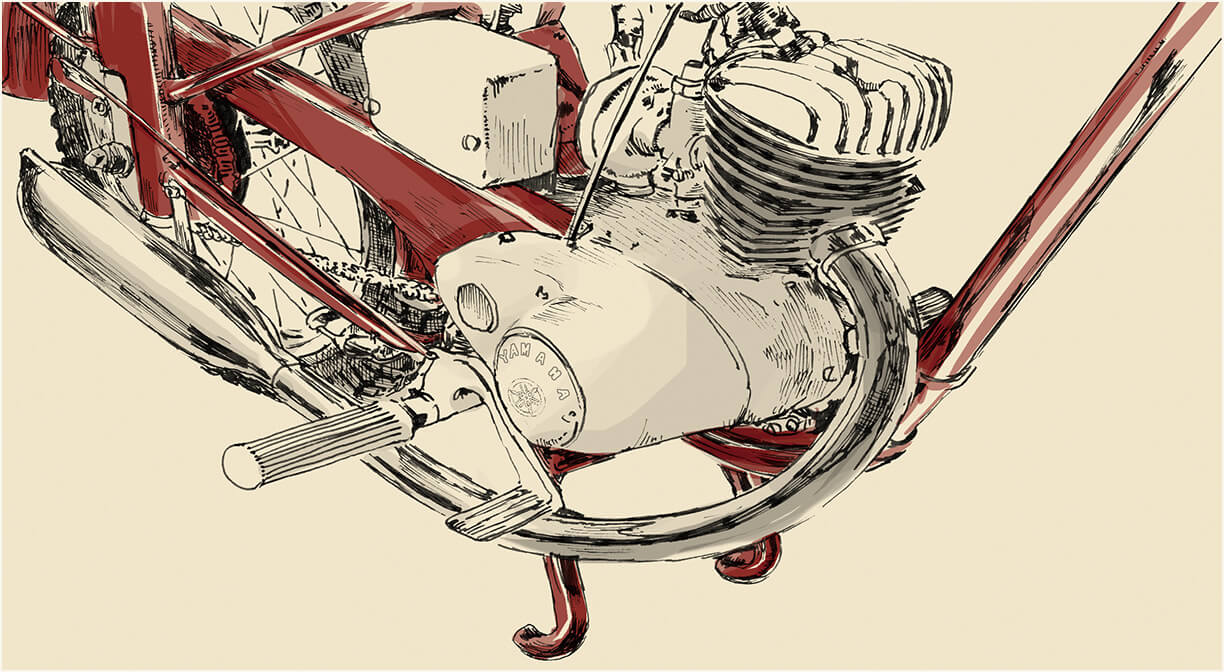

But it was not just the salespeople shouldering a heavy burden; the factory floors had their own hefty share of trouble. The engineers adapted the casting techniques for making piano frames to casting engine cylinders. But that proved to be wholly inadequate; the first prototype cylinder castings were ridiculed as ugly lumps of iron that looked more like clay teapots than engine parts. But the manufacturing teams persisted, and through much trial and error succeeded in mastering quite high-precision casting techniques for the time. This is how they created the beautiful cylinder on the YA-1 engine—a testament to their efforts.

However, having roots in the musical instrument industry meant that the newborn motorcycle manufacturer and its employees had a keen sense that set them apart. A clear example is the value they placed on craftmanship with an aesthetic appeal. This was during an era when norms dictated that home appliances be white and motorcycles be black. In contrast, the YA-1 had a stunning two-tone maroon paint scheme, ceramic cloisonné emblem, a slim, elegant side silhouette and more, bringing to mind the tuned sensitivity and fine attention to detail woven into the finished work of a musical instrument artisan.

Treat the Factory Floor Like Your Own Living Room

During the mid-1950s when most factories in Japan still operated their equipment on earthen floors, Yamaha’s main factory where the YA-1 was produced was extremely advanced for the time. Although the factory was small, founder and president Genichi Kawakami wanted to create a model factory that was clean, efficient and well-organized.

To that end, wooden flooring was installed and workers were forbidden from wearing outdoor shoes into the factory. Shoe shelves were placed at the entrances and workers changed into their indoor shoes before starting work. “Treat the factory floor like your own living room” was the policy put in place, and Yamaha began production of its first motorcycle in a very clean facility.

Also, a large sign saying “Absolute Quality” was hung up in the factory rafters above the lines. “We must never cause trouble for customers that put their faith in Yamaha and purchased our product.” This too was one of President Kawakami’s firm beliefs.

Where People Teach, Learn and Grow

At Yamaha’s Monozukuri workplaces, nurturing new talent is considered a treasured tradition. “Like most, I also gained years as well as experience in that close, familial atmosphere. If you show the person that you value them while teaching them the fun and joy of Monozukuri, they will without a doubt teach the next generation the same way,” says one manager. “This is a place where people teach, learn and grow,” claims another. “Even if the times change the way things are done, this positive culture will always be passed on.”

Foreperson Circle is an informal study group with a history spanning nearly 50 years, with the meetings gathering the heads of the company’s numerous production divisions. It is through these meetings that the production heads themselves not only look to improve their own skills as well as those of their peers, but also to hold various lectures and share ideas for teaching the next generation of Yamaha Monozukuri specialists.