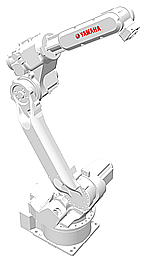

Launch of New 'YA Series' Articulated Robots, New Lineup Responds to Wide Range of Automation Needs

September 18, 2015

IWATA, September 18, 2015 – Yamaha Motor Co., Ltd (Tokyo: 7272) announces sale of eight new 'YA Series' articulated robots, which respond to a wide range of automation needs in production processes, from December 10, 2015.

Through adding the new 'YA Series' to its existing lineup, which focuses on linear conveyor modules, single-axis robots, cartesian robots, and SCARA robots, Yamaha Motor will now deliver optimal total solutions suited to customer needs in conveying, supply, assembly, and inspection across a wide range of production processes.

Developed in pursuit of high speed and space saving, the 'YA Series' articulated robots contribute to increased productivity and downsizing in production facilities.

Product variations include the five 'YA-RJ', 'YA-R3F', 'YA-R5F', 'YA-R5LF', and 'YA-R6F' six-axis robot models, which feature class-leading motion speed on each axis and high joint load capacity. The lineup also includes the three 'YA-U5F', 'YA-U10F', and 'YA-U20F' seven-axis robot models, which achieve flexibile arm operations through their use of elbow axis. These new models are all driven and controlled by the new 'YA-C100' model controller.

In order to meet diverse customer needs, in recent years manufacturing sites are changing from the traditional model of large-volume production of small numbers of products to low-volume production of wide ranging products, with the mainstream of production methods changing from line-production systems to cellular-type manufacturing. Based on these changes in manufacturing, a trend is visible from single-purpose robots, which are only required to perform one role, to multi-purpose robots, which are required to perform several roles. It is anticipated that multi-purpose robots will account for a major proportion of the market in the future. The 'YA Series' of multi-purpose robot products are compatible with high-level automation in cellular-type manufacturing.

These products are scheduled for exhibition at the International Robot Exhibition 2015, to be held from December 2 to 5 2015 at the Tokyo Big Sight.

| Model | Price | Sales Period | Target Sales | |

|---|---|---|---|---|

| Six-axis control robots | 'YA-RJ', 'YA-R3F', 'YA-R5F', 'YA-R5LF', and 'YA-R6F' |

Open Price | December 2015 | 400 units annually (total of eight models) |

| Seven-axis control robots | 'YA-U5F', 'YA-U10F', and 'YA-U20F' |

Product Features

Six-axis control robots: 'YA-RJ', 'YA-R3F', 'YA-R5F', 'YA-R5LF', and 'YA-R6F'

- 1.

- Contributing to increased productivity through high-speed motion

New design that incorporates the adoption of high-speed, low-inertia AC servo motors as well as lightening of the arms.

Latest control technology achieves class-leading motion speed on each axis.

- 2.

- Compact, lightweight, and space-saving

Compact, lightweight, and space-saving form makes for simpler inclusion in larger apparatus, transport, and for installations.

- 3.

- High joint load capacity

Easily copes with simultaneous handling of multiple pieces due to the class-leading joint tolerable moment, increasing the range of applicable pieces.

Seven-axis control robots: 'YA-U5F', 'YA-U10F', and 'YA-U20F'

- 1.

- Flexible arm operations

These robots deliver supple and flexible movement similar to the human arm, enabling a low crouching posture and motions reaching around the back of the apparatus.

- 2.

- The space-saving form enables high-density system layouts

By including axes equivalent to the elbow, these robots have a high degree of freedom in movement such as bending, twisting, and telescoping. This makes possible operations that people and previous robots struggled with, such as installation and work in narrow crevices.

- 3.

- All cables housed internally

Through the employment of hollow-structure actuators, the installed cables and air hoses have all been housed within the arm. This enables minimization of interference with surrounding equipment and a compact line design.

Basic Specifications

| Item | YA-RJ | YA-R3F | YA-R5F | YA-R5LF | YA-R6F | YA-U5F | YA-U10F | YA-U20F | |

|---|---|---|---|---|---|---|---|---|---|

| Controlled Axis | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | |

| Payload | 1Kg | 3Kg | 5Kg | 5Kg | 6Kg | 5Kg | 10Kg | 20Kg | |

| Reach | 545mm | 532mm | 706mm | 895mm | 1422mm | 559mm | 720mm | 910mm | |

| Repeatability | ±0.03mm | ±0.03mm | ±0.02mm | ±0.03mm | ±0.08mm | ±0.06mm | ±0.1mm | ±0.1mm | |

| Maximum speed | S axis (turning) | 160°/s | 200°/s | 376°/s | 270°/s | 220°/s | 200°/s | 170°/s | 130°/s |

| L axis (lower arm) | 130°/s | 150°/s | 350°/s | 280°/s | 200°/s | 200°/s | 170°/s | 130°/s | |

| E axis (elbow twist) | - | - | - | - | - | 200°/s | 170°/s | 170°/s | |

| U axis (upper arm) | 200°/s | 190°/s | 400°/s | 300°/s | 220°/s | 200°/s | 170°/s | 170°/s | |

| R axis (wrist roll) | 300°/s | 300°/s | 450°/s | 450°/s | 410°/s | 200°/s | 200°/s | 200°/s | |

| B axis (wrist pitch/yaw) | 400°/s | 300°/s | 450°/s | 450°/s | 410°/s | 230°/s | 200°/s | 200°/s | |

| T axis (wrist twist) | 500°/s | 420°/s | 720°/s | 720°/s | 610°/s | 350°/s | 400°/s | 400°/s | |

| Allowable Moment |

R axis (wrist roll) | 3.33N・m | 5.39N・m | 12N・m | 12N・m | 11.8N・m | 14.7N・m | 31.4N・m | 58.8N・m |

| B axis (wrist pitch/yaw) | 3.33N・m | 5.39N・m | 12N・m | 12N・m | 9.8N・m | 14.7N・m | 31.4N・m | 58.8N・m | |

| T axis (wrist twist) | 0.98N・m | 2.94N・m | 7N・m | 7N・m | 5.9N・m | 7.35N・m | 19.6N・m | 29.4N・m | |

| Allowable Inertia (GD2/4) |

R axis (wrist roll) | 0.058kg・m2 | 0.1kg・m2 | 0.3kg・m2 | 0.3kg・m2 | 0.27kg・m2 | 0.45kg・m2 | 1.0kg・m2 | 4.0kg・m2 |

| B axis (wrist pitch/yaw) | 0.058kg・m2 | 0.1kg・m2 | 0.3kg・m2 | 0.3kg・m2 | 0.27kg・m2 | 0.45kg・m2 | 1.0kg・m2 | 4.0kg・m2 | |

| T axis (wrist twist) | 0.005kg・m2 | 0.03kg・m3 | 0.1kg・m4 | 0.1kg・m4 | 0.06kg・m6 | 0.11kg・m2 | 0.4kg・m2 | 2.0kg・m4 | |

| Weight | 15Kg | 27Kg | 27Kg | 29Kg | 130Kg | 30Kg | 60Kg | 120Kg | |

| Controller used | YA-C100 | ||||||||