Yamaha Motor Releases the new GF14XL and GF17XL, New additions to the long-stroke single-axis robot lineup in the FLIP-X series

September 9, 2014

IWATA, September 9, 2014 – Yamaha Motor Co., Ltd. (Tokyo:7272) will release two new models to the servo motor driven single-axis robot FLIP-X series: GF14XL and GF17XL.

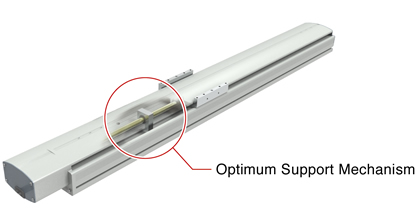

Production facilities can have multiple requirements such as long-stroke, high-speed, and high-precision capabilities. However, for single-axis robots using ball screws, there were hurdles of top speed becoming compromised as their stroke became longer. The new GF14XL and GF17XL are able to run full stroke at its maximum speed thanks to Yamaha Motor's unique "Optimum Support Mechanism" (patent pending) while maintaining the level of precision achieved by previous models with the use of ball screws. These features realize long-stroke, high-speed, and high-precision capabilities.

The new products will answer to the needs of customers who require not only long-stroke capability but also other features, and allows the selection of the most appropriate single-axis robot for their production facility.

| Model | Price | Launch Date | Target Sales |

|---|---|---|---|

| GF14XL | Open price | September 11, 2014 | 1,000 Units (first full year from release, both within Japan and internationally) |

| GF17XL | Open price |

Product Features

Ability to operate at its maximum speed even for longer strokes

Yamaha Motor's unique "Optimum Support Mechanism", which controls ball screw vibrations by the placement of supporting components, allows the robot to operate at its maximum speed for a full stroke length. This feature may then lead to tact time improvements even in long-stroke operation.

Resolvers on position detectors realize environmental resistance and high reliability

Resolvers are featured on the position detectors, which are driven magnetically. Resolvers do not use electronic components that are prone to external interference, and are widely used in fields such as the automotive, aerospace, and medical industries, where reliability is most vital. The use of resolvers on position detectors provides environmental resistance and reliability.

Compact cross-sectional area

The cross-sectional area is more compact when compared to previous single-axis robots with long-stroke capabilities - it is smaller by 40% or more compared with linear and rotating nut single-axis robots that require cableveyors.

Basic Specifications - GF14XL, GF17XL

| Models | GF14XL | GF17XL |

|---|---|---|

| Motor output | 200W | 400W |

| Repeatable positioning accuracy | ±0.01mm | |

| Speed reduction mechanism | Ball screwφ15 (Grade: C7) |

Ball screwφ20 (Grade: C7) |

| Ball screw lead | 20mm | |

| Maximum speed | 1200mm/sec | |

| Maximum payload (horizontal) | 45kg | 90kg |

| Rated thrust | 170N | 339N |

| Stroke | 750~2000mm (50mm pitch) |

850~2500mm (50mm pitch) |

| Length | Stroke+561mm | Stroke+686mm |

| Maximum cross-section external dimensions | W140×H91.5mm | W168×H105.5mm |

| Cable length | Standard: 3.5m (Optional: 5m, 10m) | |

| Linear guide type | 4-row circular arc x 2 rails | |

| Position detector | Resolver | |

| Resolution | 20480 pulse/revolution | |