Super High Efficiency Dual Lane Modular YRM20DL Feature

1 head solution 최종 단계에 도달했습니다. 뛰어난 생산성, 유연성 및 PCB 작업 능력을 제공하는 이중 레인 표면 실장기.

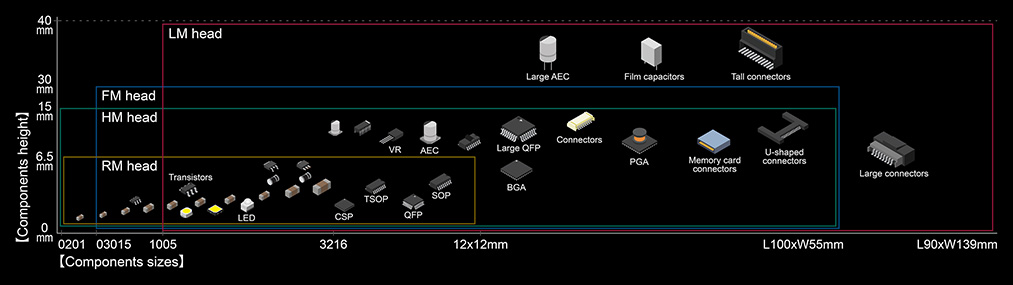

1 head solution provides broad-range production capability

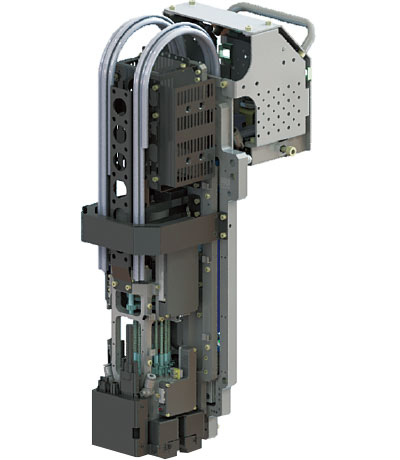

Super high-speed rotary RM head achieves 120,000CPH

로터리 헤드는 소형 부품의 부품 실장성을 높이고, 헤드 교체가 더 이상 필요하지 않으므로 고속 생산이 유지됩니다.이것이 1헤드 솔루션 개념을 이끌어가는 기술입니다. 이 헤드는 6.5mm 높이의 12 x 12mm 치수의 초소형 0201mm 구성 요소에서 최대 중간 크기의 이상한 모양 구성 요소에 이르는 구성 요소를 처리할 수 있습니다.

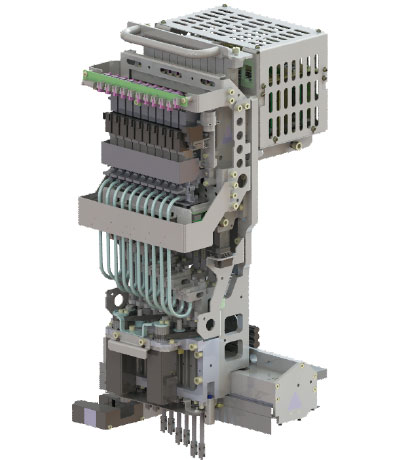

고속 다목적 인라인 HM 헤드

The flexible “all-around” head not only has high-speed, but also has the versatility essential for mounting super-tiny 0201mm components all the way up to large-size components of 55 x 100mm and heights up to 15mm.

인라인 FM 헤드가 가능한 이상한 모양의 부품

The ultra-wide-range head fully handles components ranging from super-tiny 03015mm chips on up to ultra-large components of 55 x 100mm and heights of 30mm. Force control is also available.

RM head / HM head / FM head

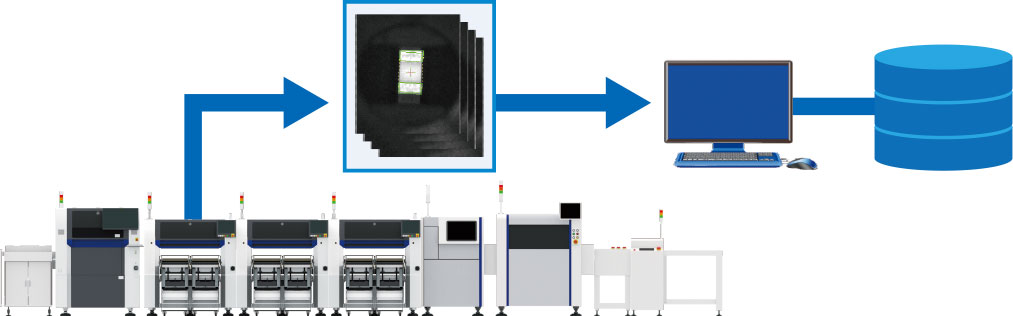

Solution for variable-mix, variable volume production

Takes on various types of production with super high efficiency

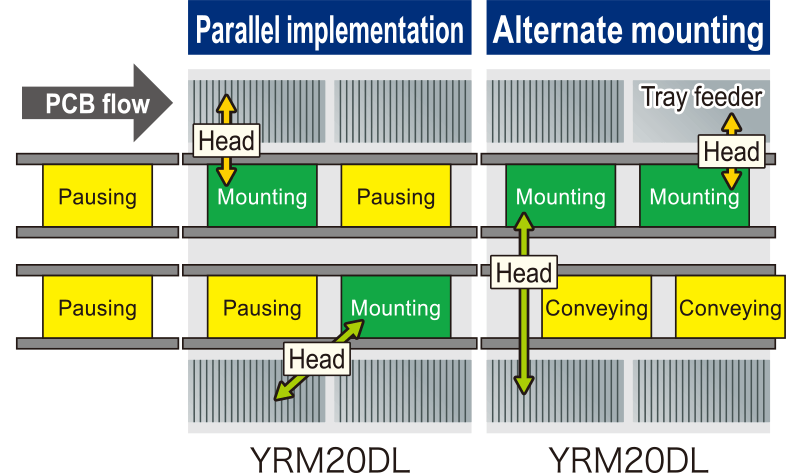

Ensures super high efficiency for production of various types, by combining parallel mounting and alternate mounting, and 4-stage mounting with the newly developed dual-lane conveyor. Achieves high productivity even when production type varies by lane.

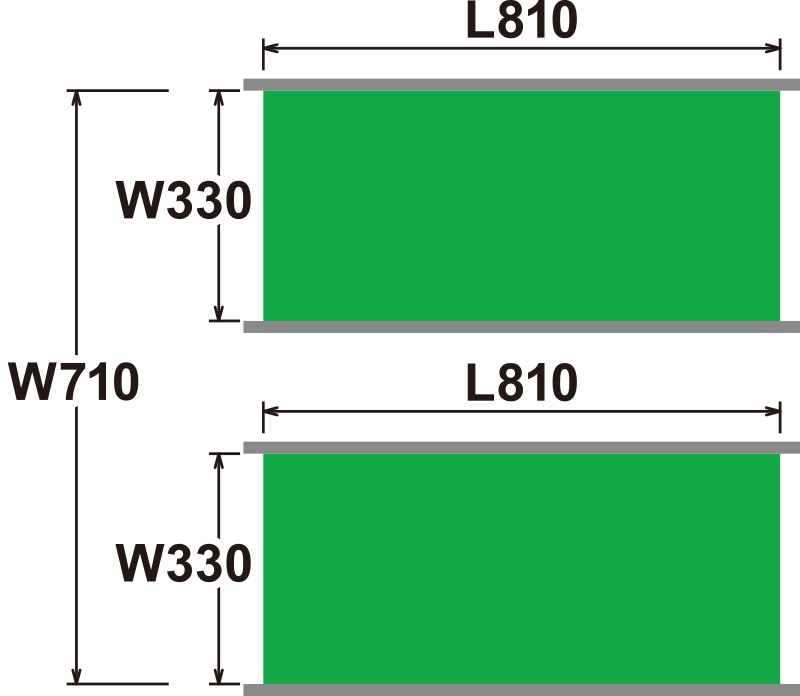

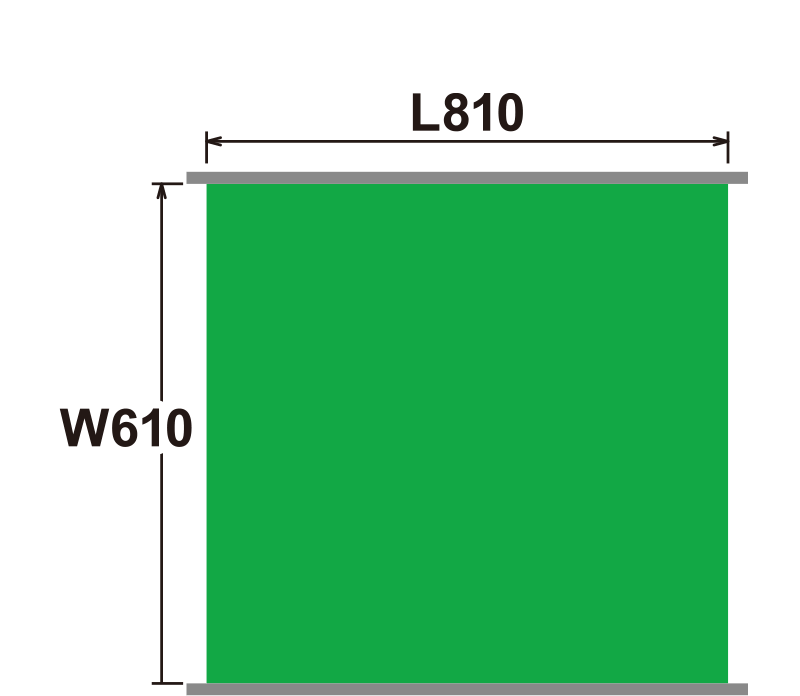

W330mm Dual lane

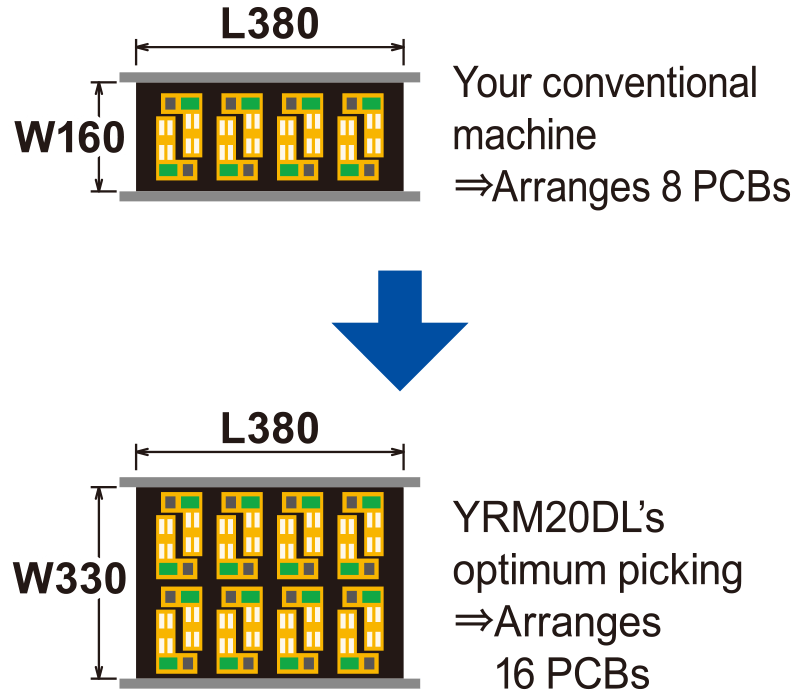

Produces L-size PCB of up to L810×W330mm in Dual-lane. Can increase PCBs to be picked up and carriers transported, raising production efficiency.

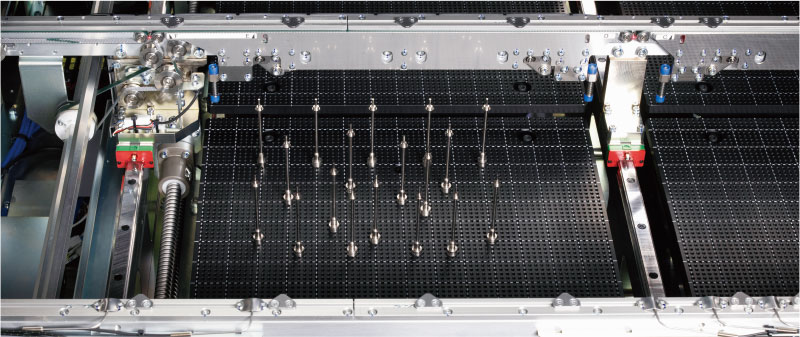

Automatic push-up pin exchange system Included in the automotive PKG

푸시업 핀이 자동으로 배치됩니다. 자동 프로그램 전환 기능과 함께 사용하면 생산 전환 시 작업량을 크게 줄일 수 있습니다.

Auto nozzle station Included in the automotive PKG

The nozzle is automatically exchanged for efficient production. The nozzle holder can be exchanged with a single touch which makes setup and maintenance easy.

High accuracy mounting and steady production of micro components

High accuracy mounting level of ±15μm (Cpk≧1.0)

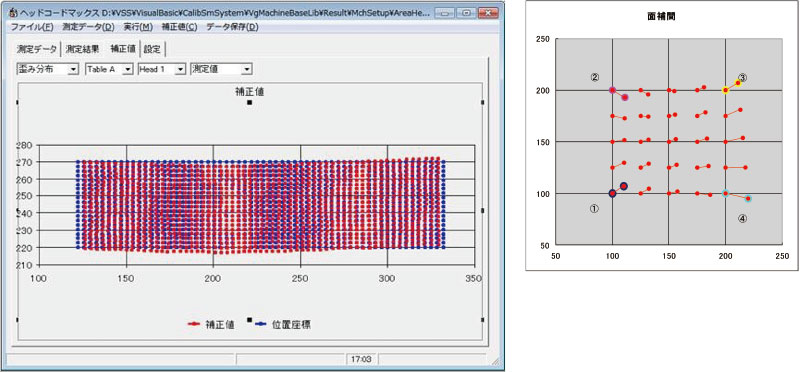

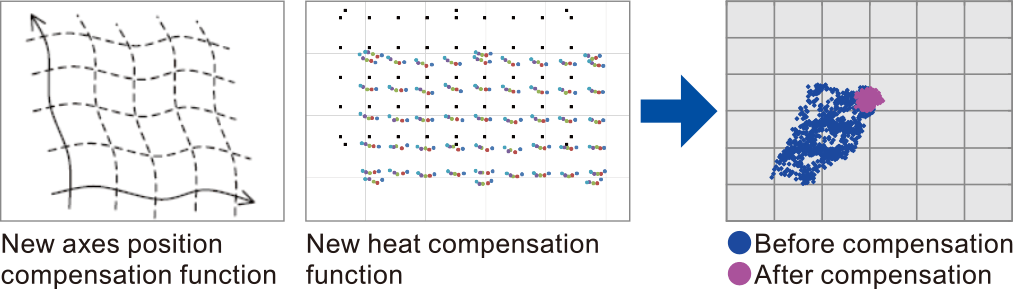

Machine vibration controlled with a very stiff base, etc., and adjustment accuracy improved with Coord MACS, achieving a high accuracy mounting level of ±15μm.

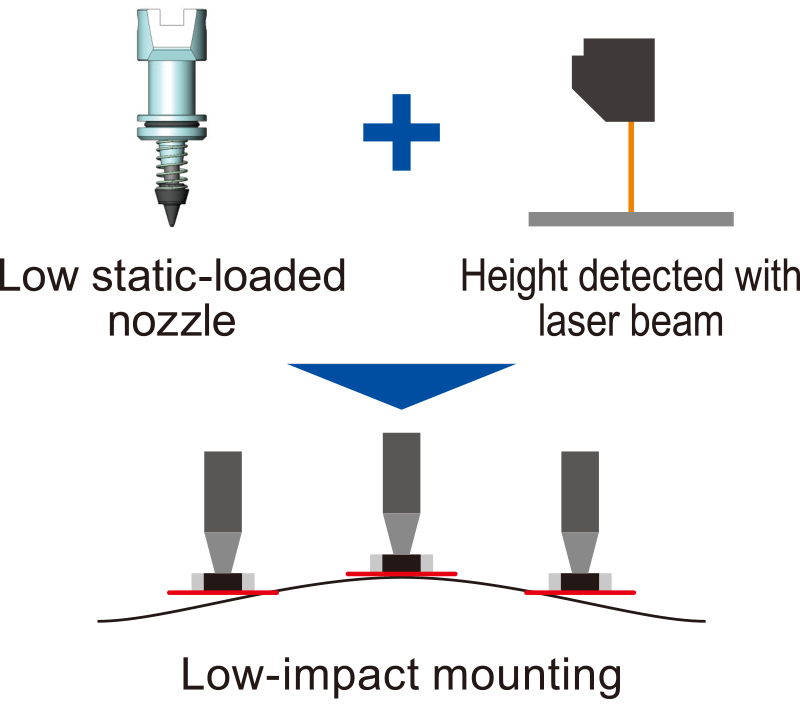

Low-impact mounting

Relative height of the mounting surface and component bottom controlled by measuring PCB height to control mounting height, which minimizes impact on micro components together with a low static-loaded nozzle.

Steady pick-up and mounting

Multiple Accuracy Compensation System “MACS” realises stable pick-up and mounting by recognizing correction marks in the machine during production.

High-efficiency production with various features

Non-stop tray feeder eATS30

High-capacity tray feeder that can store up to 30 pallets. Provides a non-stop supply of tray components, achieving non-stop production. The lineup also includes a 10-stage tray component feeder “cATS10R” as well, with excellent space savings and cost performance.

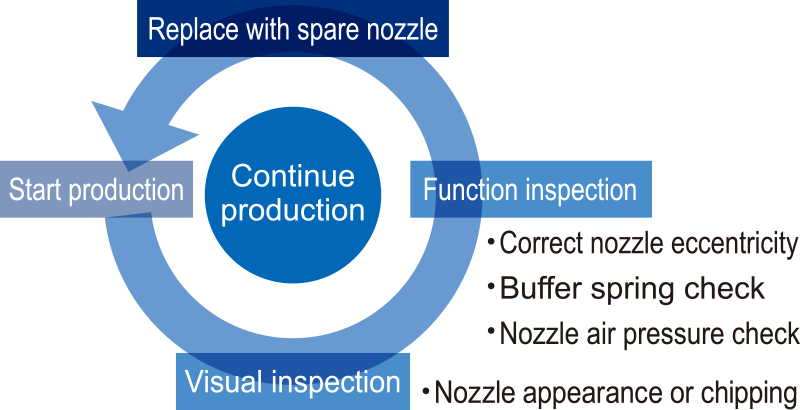

노즐 및 피더 유지보수 경고

Self-diagnosis and self-recovery functions continuously maintain nozzles and feeders in a clean state for continuous high-quality production.

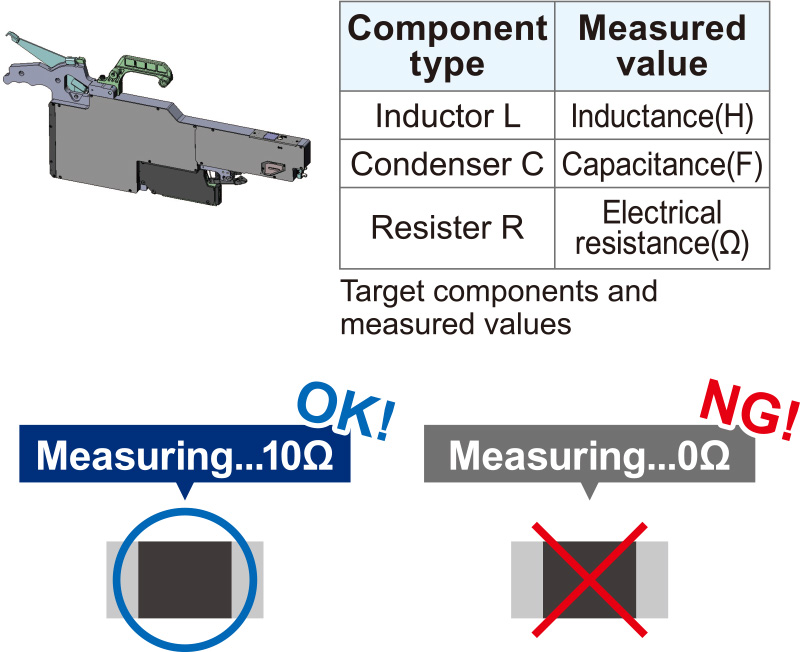

LCR verification

Measures the electrical properties of the chip components and ensures steady loading of components without errors.

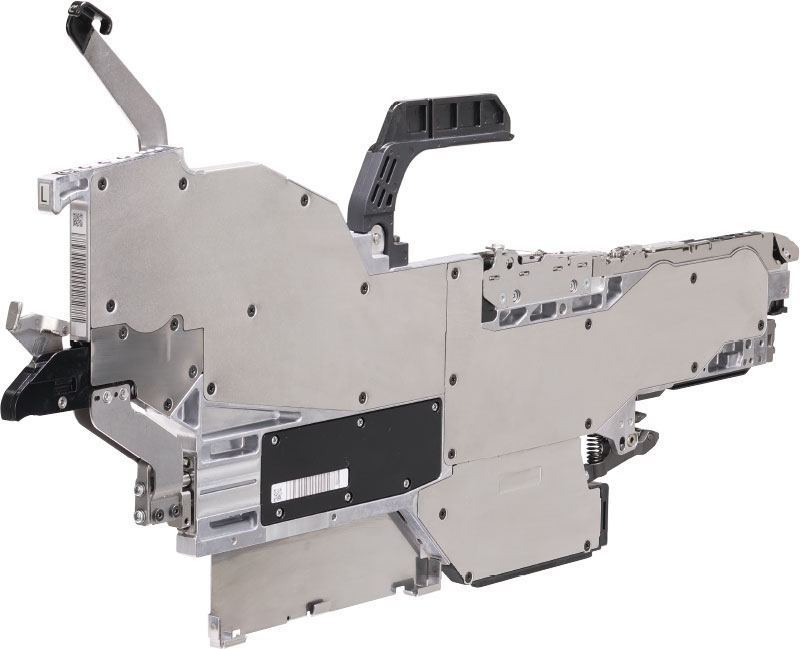

자동 로딩 피더

테이프를 자르고 삽입하는 간단한 작업은 부품 공급 작업의 부하를 줄입니다. 2개의 릴을 설정하면 부품 공급 타이밍을 균일하게 할 수 있어 부품 공급 실패로 인한 라인 중단 위험을 최소화할 수 있습니다.

부품 실장 품질을 더욱 향상시키는 비전 시스템

The side-view camera improves quality for mounting of tiny components. Coplanarity checker can also be installed as an option. All Image Tracer Plus (option) saves every component recognition image, providing strong support for analysis of the mounting quality.