MZ Series Features

Introduction to the special features of our Multi Purpose Engine.

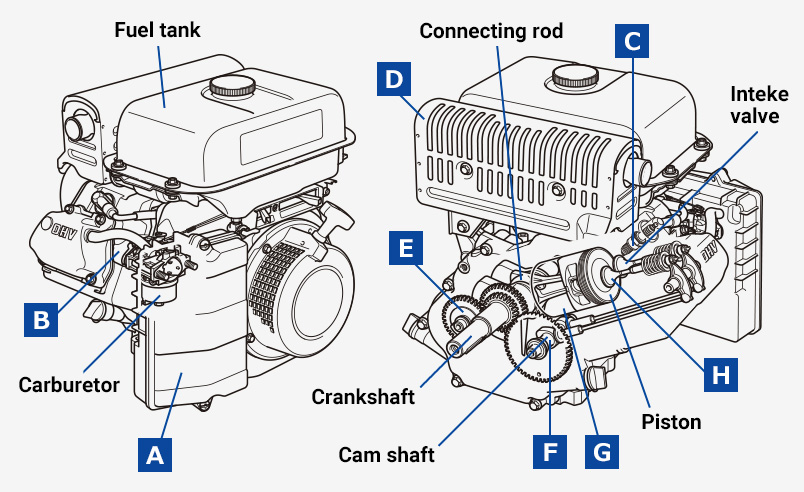

Components

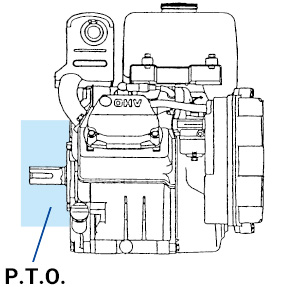

Clean P.T.O. face

The mounting face of the P.T.O. side, MZ engine is almost flat against applications. This will make customer easier to apply their product fit against our engine compare to others.

- Variety of P.T.O. shaft

- Meets latest emission standard in each country

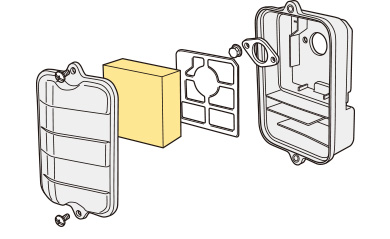

Air cleaner Various air cleaner selection

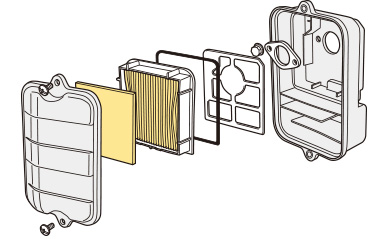

Silent semidry type

| DUST CONDITION |

|---|

| Low dust condition |

| APPLICATION EXAMPLE |

| Stationary engines such as pump and generator rice-planting machine |

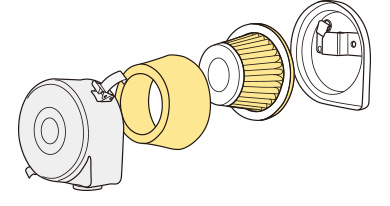

Silent dual type

| DUST CONDITION |

|---|

| Intermediate dust condition |

| APPLICATION EXAMPLE |

| Harvesting machines (binder, harvester) Caring machines (tiller, etc.) |

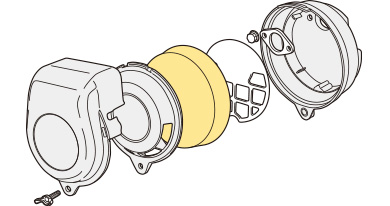

Semi-cyclone type

| DUST CONDITION |

|---|

| Severe dust condition |

| APPLICATION EXAMPLE |

| Construction machinery・・late, rammer, etc.・・ Harvesting machines・・inder, harvester, etc.・・ Caring machines・・arth-scattering machine・・ |

Semidry type

| DUST CONDITION |

|---|

| Low dust condition |

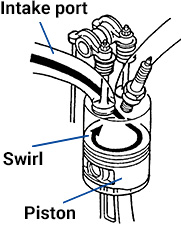

Intake manifold

MZ engine mixture air goes into the cylinder having swirl. Mixture air needs to go into the cylinder uniformly. Also during compression and combustion, having swirl will increase the speed of plug spark spread through the mixture air. This increases the power, fuel consumption, and cleanliness exhaust emission.

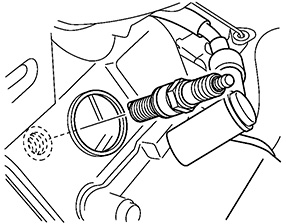

Spark plug

Register plug for noise reduction. Standard equipped a resistance type SPARK PLUG The mounting face of the P.T.O. side, MZ engine is PR4ES.

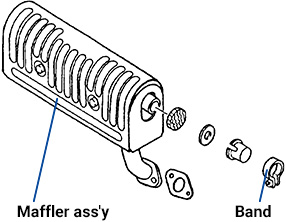

Muffler

The adoption of a large muffler reduces the exhaust noise. The tail screen is also adopted to MZ125 and MZ175.

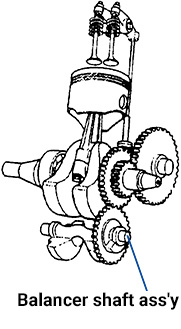

Balancer [MZ360]

MZ engine has one balancer on 360. Big capacity single cylinder engine is able to get larger vibration. In order to cure this, balancer is needed. Balancer shape, style, and quantity depend on each company way of thinking.

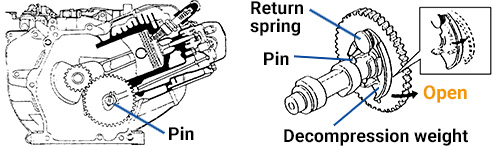

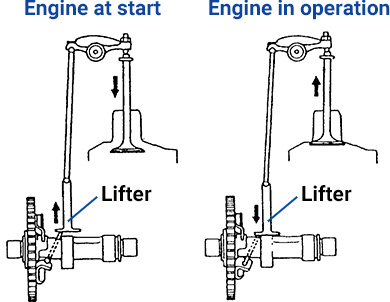

Decompression

When starting the engine, the compression pressure is reduced by forcing the exhaust valve to open, thus facilitating the start operation.

- When stopping/starting the engine:

- 1) The decomp weight pushes up the pin to push the lifter.

2) The exhaust valve is not opened or closed as the camshaft turns but forced to open.

- When operating engine:

- 1) The centrifugal force causes the decomp weight to open, and this movement lowers the pin. 2) The lifter is not forced to be pushed up but normally moves as the camshaft turns. 3) The exhaust valve is not opened and closed with the normal timing.

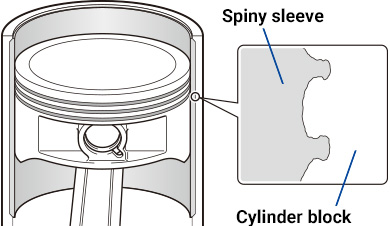

Sleeve

Spiny sleeve is used. Since the engine block is aluminum, cast iron sleeve is fitted for more durability and less worn out. This sleeve is called spiny sleeve that has special shape. When aluminum and steel expands by heat, their expand rate is different(aluminum is more than steel). This difference will create air pockets but with spiny sleeve is keeps this level very small. Spiny sleeve is shaped liked jigsaw puzzle and even if aluminum and steel expands in different ratio, the air pocket will not occur largely. This will help to radiate the engine inside heat transfer to sleeve, block, and fin and keep the engine temperature in more idealistic figure.

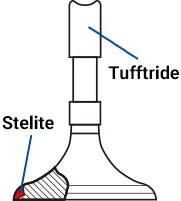

Exhaust valve

High heat resistant SUH3 steel is used. But since exhaust valve expose to more than 700 degrees Celsius instantly, at the valve face where it meets valve seat has stellite coating. Also, whole valve surface has tufftride finish in order to increase the hardness. Together when this tufftride finish is polished, friction of surface becomes very low which makes valve to move smoother against guides.