The Origins of Yamaha’s LMW Technology? Chopsticks.

介绍雅马哈发动机技术背后的故事。

Tricity 125 是雅马哈首款量产的多轮 (LMW) 车型,该技术的核心重点是为其配备两个前轮。 Tricity 的底盘后部采用传统踏板车底盘,底盘前部采用两轮结构,使其成为 LMW 车辆。

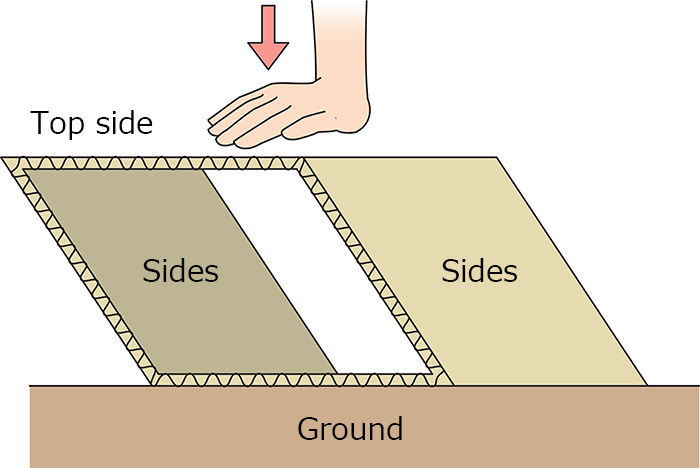

但是前部装配如何倾斜?如果这有点难以想象,您可能可以通过打开纸板箱的顶部和底部,将其侧翻,然后向下推(#1)来很好地了解所涉及的动态。在这种情况下,盒子的左右两侧代表两个前轮及其悬架,顶部代表连接两个前轮和底盘的机构,底部的一侧是地面。

事实上,在开始开发 Tricity 后不久,项目负责人 Kazuhisa Takano 使用了两种常见的家居用品来验证两个前轮的基本工作原理:一次性木筷子和橡皮筋。

他把筷子掰成合适的长度,纵横对齐,用橡皮筋把它们绑在一起,使结构变得灵活。通过创建他心目中的结构的 3D 模型,他能够更好地确认其设计的有效性。

The Two Fundamental Mechanisms of the LMW Design

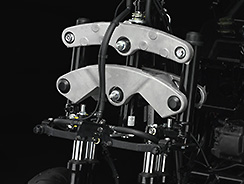

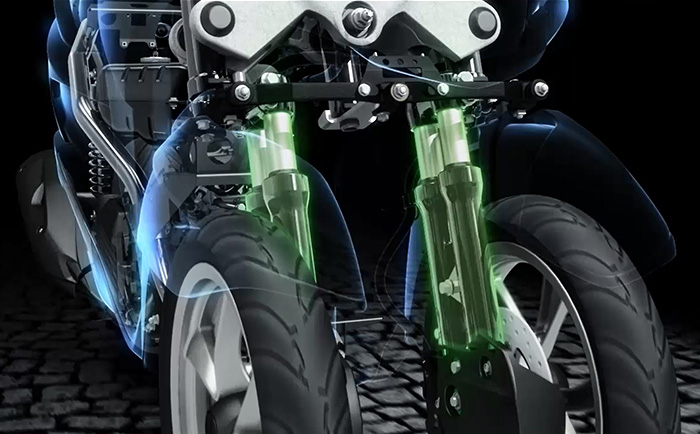

To achieve performance with a good feeling of agility, lightness and stability in a vehicle configuration with two front wheels and one rear wheel, the front assembly of the Tricity 125 employs independent right and left cantilevered telescopic suspensions that are supported and connected to the chassis by means of a parallelogram link mechanism (#2).

This system separates the mechanisms for allowing the two front wheels to lean and suspension functionality, and makes it possible to achieve both a deep lean angle and a large steering angle for the handlebars, which contribute to the Tricity’s light and agile feel.

Parallelogram Link: Producing Natural Lean Characteristics with a Good Feeling of Stability

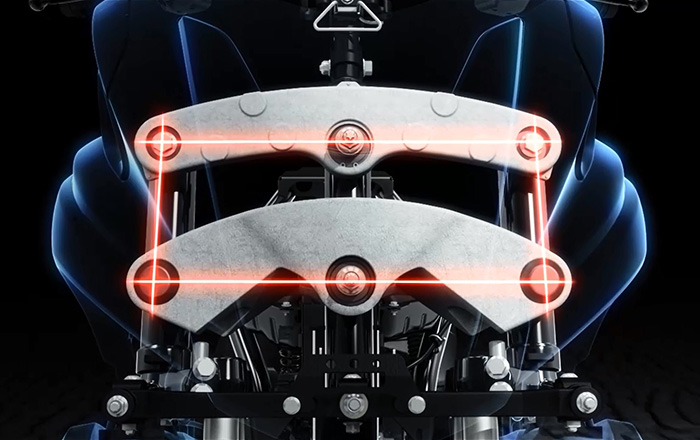

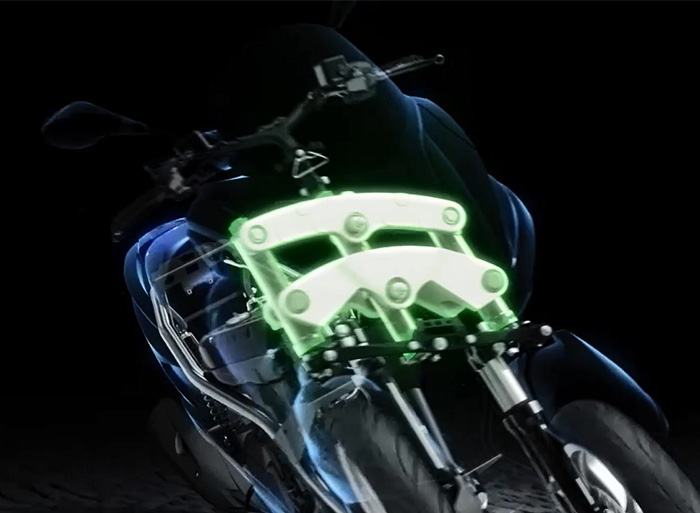

By enabling the two front wheels to lean in concert with the chassis when turning, the LMW mechanism brings a natural feel to the handling. The essential component for achieving this is the parallelogram link (#3) mechanism that supports the left and right independent suspensions of the two front wheels and connects them to the chassis.

The link itself is composed of two arms that are always parallel to each other and are positioned one above the other. With the right and left suspensions connected to them, the link assembly takes the form of a rectangle when seen from the front with the vehicle upright and a parallelogram when the machine is leaning.

The basic construction of the parallelogram link is simple and enables a lighter and more compact unit. And, because there is little change in the width between the right and left tires where they contact the ground, it achieves natural handling qualities with a good feeling of stability.

Cantilevered Telescopic Suspension: Contributing to Weight Reduction and More

For the front suspension, there was a choice between the telescopic type commonly used on conventional motorcycles and the bottom-link type used on some scooter models. Considering the balance between each type’s merits and demerits and the goal of achieving a natural feel to the ride, the telescopic type was chosen.

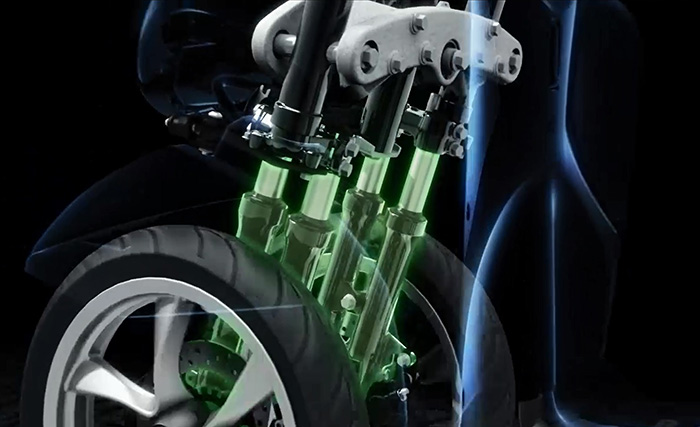

At first, using forks that straddle the wheels to hold the axles from both sides were under consideration, but from the perspective of design and other factors, it was decided to use cantilevered types (#4). The end result is the Tricity using two independent forks to hold the insides of the two front wheels in what is now one of the vehicle’s iconic design points. This structure not only enabled a lighter and slimmer chassis design, but it also proved to be the better choice for achieving the various functional qualities desired for an LMW vehicle.

Concerning the tubes on the two cantilevered forks for each wheel, the front-set tubes function as guides while the rear-set tubes handle shock-absorbing.

Differences between a Telescopic and Bottom-Link Suspension

Telescopic type

Most motorcycles use this type of suspension. Two tubes of different diameters slide up and down against each other like a telescope. Excessive compression can have a negative effect on machine attitude, but it is well-suited for mass production and has excellent reliability.

Bottom-link type

This type is used on some basic scooters and commercial/utility-use models. This type makes lightweight, low-cost designs possible, but dimension limitations make it difficult to get a large amount of suspension travel.

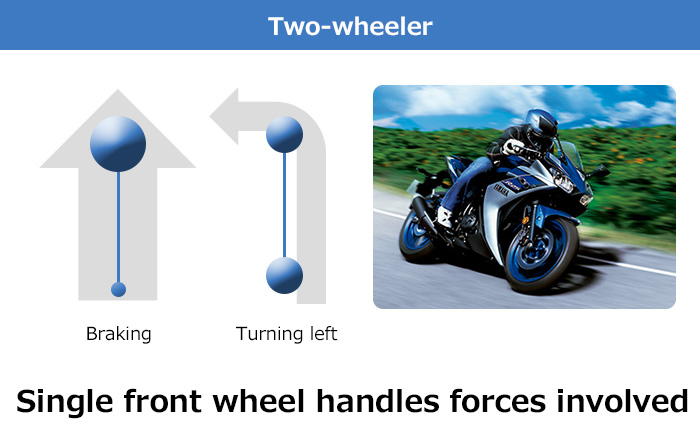

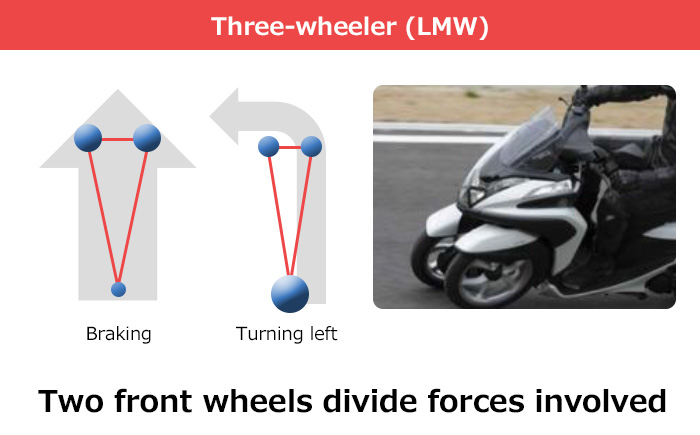

The Basic Idea is to Divide the Front Tire’s Heavy Workload

The twin-front wheel design of the Tricity divides the load placed on the front tire in a conventional layout and thus effectively reduces it. One of the main benefits of the LMW design is the confidence-inspiring feel and performance potential it brings, especially during cornering and braking (#5).

At the same time, by using Yamaha-exclusive technologies and meticulous fine-tuning to create a ride character as close as possible to a conventional motorcycle, the development team sought performance that could help more people enjoy the fun and exhilaration of leaning a machine through turns.

The Added Benefits LMWs Bring to Commuter Vehicles

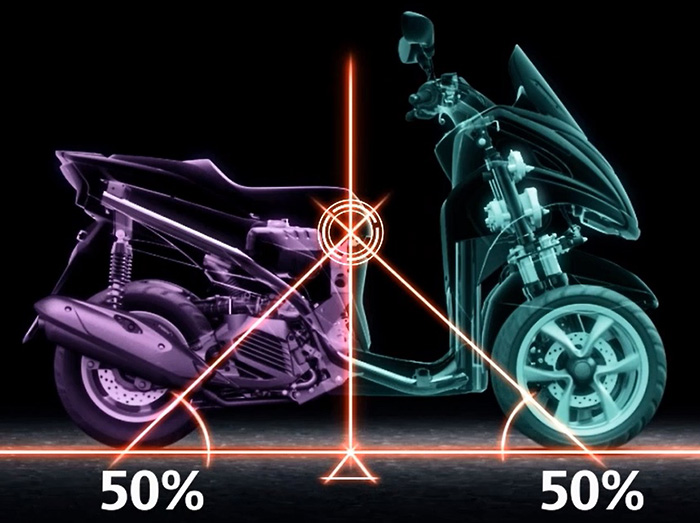

Small and mid-sized scooters typically adopt a design that combines the rear suspension components and the engine into a single “unit-swing” structure, which tends to make the rear half of the chassis heavier. But with the Tricity 125, adopting a twin-front wheel configuration naturally made it possible to achieve a more ideal front-rear weight distribution.

Creating a chassis with a front-rear weight distribution similar to a MotoGP race machine (#6) provided a foundation that made it possible to develop a ride character that is both natural and sporty.

What Are Eight Benefits of the LMW Mechanism?

Yamaha LMW vehicles are intended to let more people than ever enjoy the fun unique to riding a motorcycle. Here is a brief look at the benefits they offer in different types of riding conditions.

越过不平坦的表面 (#7)

两个前轮的独立悬架和 LMW 机构共同发挥作用,因此它们可以吸收路面水平的变化或来自道路的冲击。

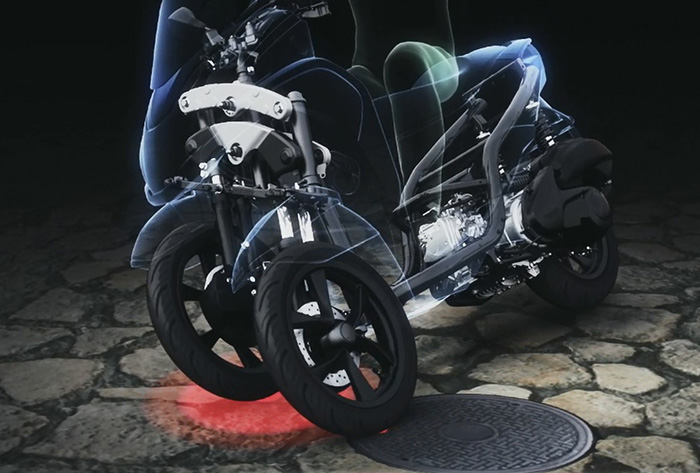

在鹅卵石或崎岖的道路上骑行 (#8)

两个前轮的独立悬架和LMW机构共同发挥作用,可以很好地吸收鹅卵石街道或崎岖路面的冲击,从而提供舒适的乘坐体验。

骑过潮湿的井盖、鹅卵石、电车轨道或沙质路面 (#9)

即使在光滑的路面上,如果 LMW 车辆的两个前轮(右或左)之一失去抓地力,只要另一个车轮保持抓地力,前轮打滑导致跌倒的风险就会降低。

巡航 (#10)

LMW 车辆提供轻便、灵活和运动的操控性,从车辆的性能中创造出一种充满自信的稳定感,带来全新的骑行乐趣。

过弯 (#11)

雅马哈独特的LMW机构,使两个前轮与底盘一致倾斜,很好地跟随路面的轮廓变化,营造出清晰的稳定感。即使在光滑的路面上转弯或转弯时,如果 LMW 车辆的两个前轮(内侧或外侧)中的一个失去抓地力,只要另一个车轮保持抓地力,前轮打滑导致跌倒的风险就会降低。

制动 (#12)

即使在直线急刹车时,LMW 车辆的前轮也难以抱死,从而降低了因前轮抱死而跌倒的风险。 LMW 车辆的两个前轮提供出色的抓地力,因此可以提供更强的制动力。

在侧风中 (#13)

即使在突如其来的侧风中,LMW车辆由于有两个前轮,机器波动很小,从而给骑手带来了清晰的稳定感。

低速运行 (#14)

因为有两个前轮,所以低速行驶时机器波动小,稳定感明显。