Forged Piston

Revs Your Heart – Explore the world of Yamaha motorcycles

Are forged pistons lighter and stronger?

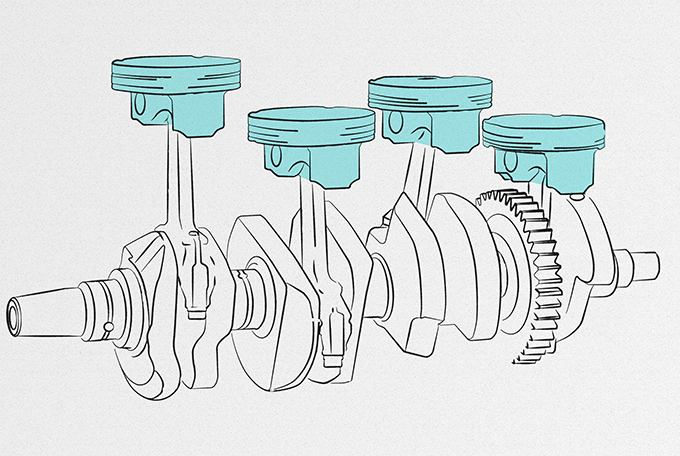

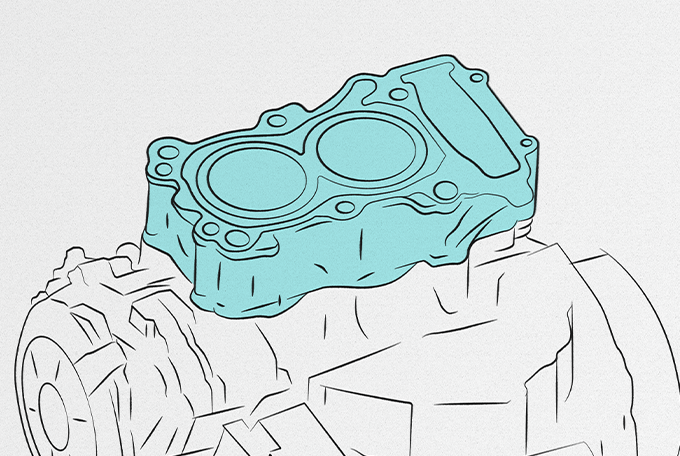

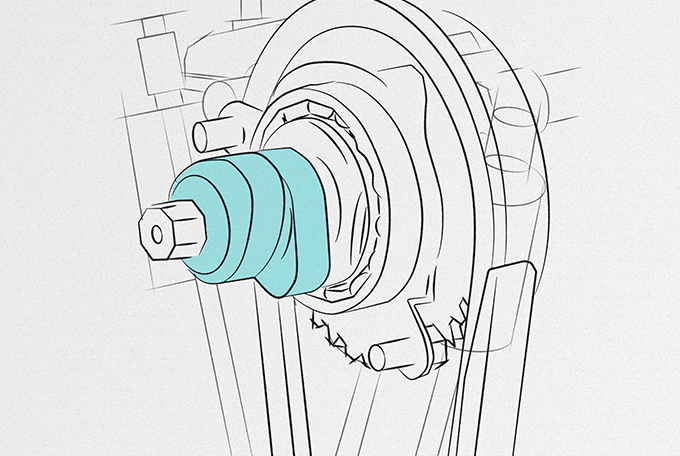

The pistons for car and motorcycle engines are very hardworking parts that are continuously subjected to reciprocating motion. Casting, which involves pouring molten aluminum into a mold and letting it harden to shape as it cools, used to be the standard method. This because it was suited for creating pistons with excellent properties, from strength to heat-resistance.

However, forged aluminum pistons are even better. Forging is performed by not melting the aluminum alloy, and instead heating it to a specific temperature below its melting point and then applying the right amount of force to press it into shape. Since the aluminum alloy isn’t melted as it is machined, there is less effect on its metallurgic structure and it retains its original strength.

This means the entire piston—including the piston walls or “skirt”—can be designed thinner and lighter, and since the piston itself is lighter, there is less wasted energy generated as it moves up and down. Compared to cast pistons, forged pistons also retain their strength better at high temperatures.

From these benefits, Yamaha actively began using forged pistons mainly on large-displacement sports models from 1996 to improve both engine power and reliability. Yamaha now uses forged aluminum pistons on numerous models, from supersport bikes to scooters for ASEAN markets, contributing to their light, agile performance.