DiASil Cylinder

Revs Your Heart – Explore the world of Yamaha motorcycles

What is DiASil? Where does the word come from?

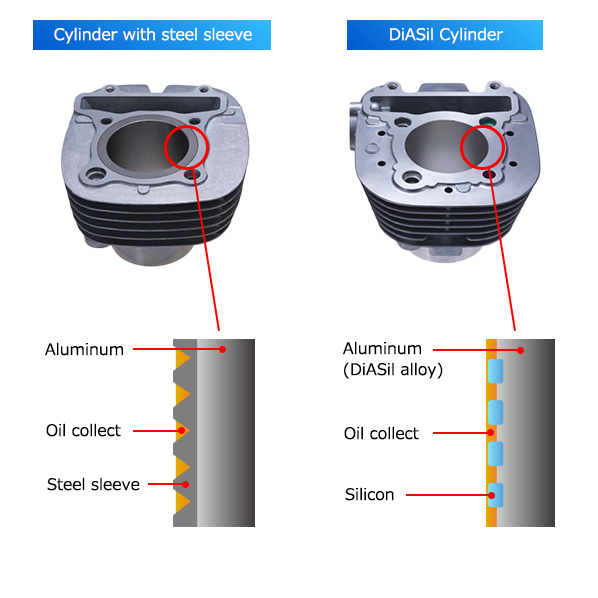

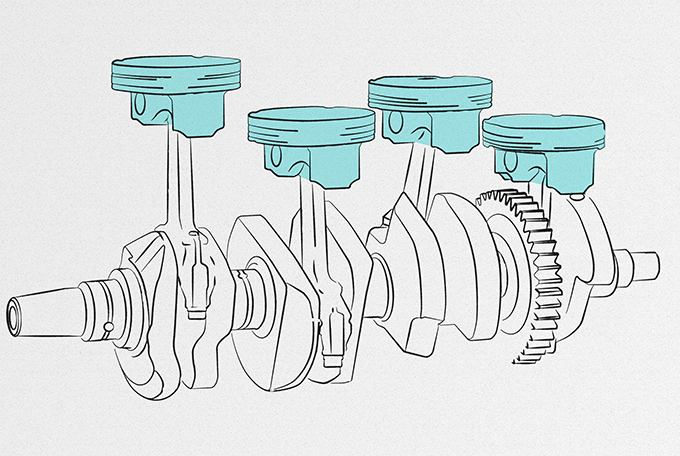

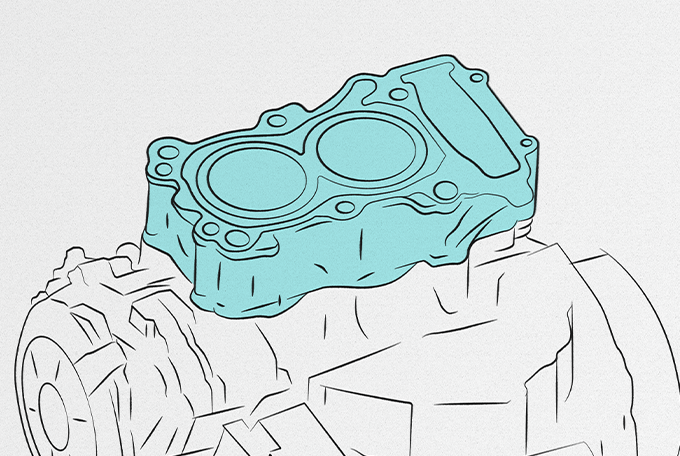

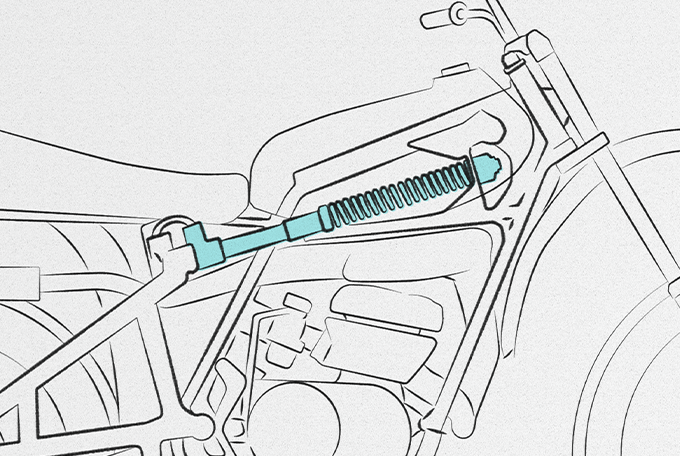

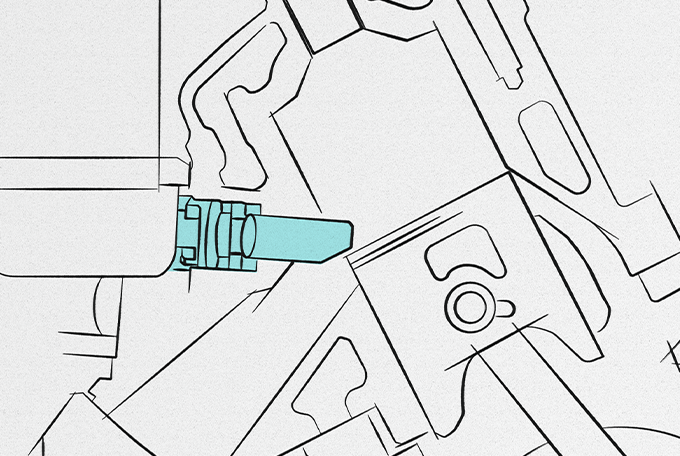

A “DiASil Cylinder” is Yamaha’s exclusively developed all-aluminum cylinder body design. Thanks to its one-piece construction, it eliminates the need for a steel cylinder sleeve to reduce wear and has excellent heat dissipation, giving it the advantages of more stable engine performance and lower weight.

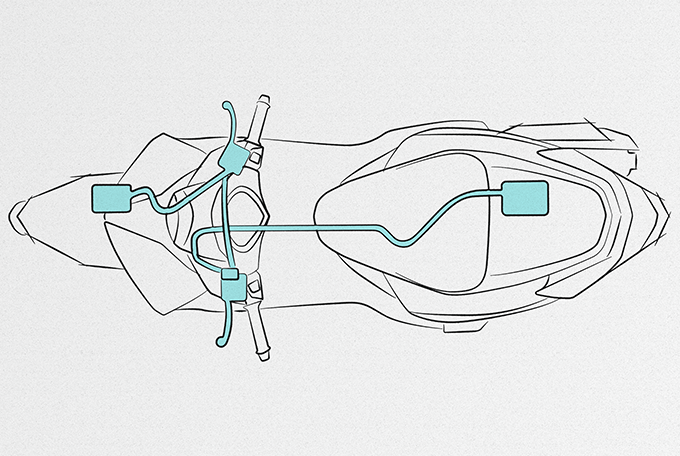

But, how is this cylinder designed? Well, to use a cooking analogy, imagine that the cylinder walls are like a pizza baking in the oven with the toppings like onions and pepperoni floating on top of the cheese. When olive oil is poured on it, the oil fills in the gaps between the toppings. This is not a very technical example, but that’s the general idea.

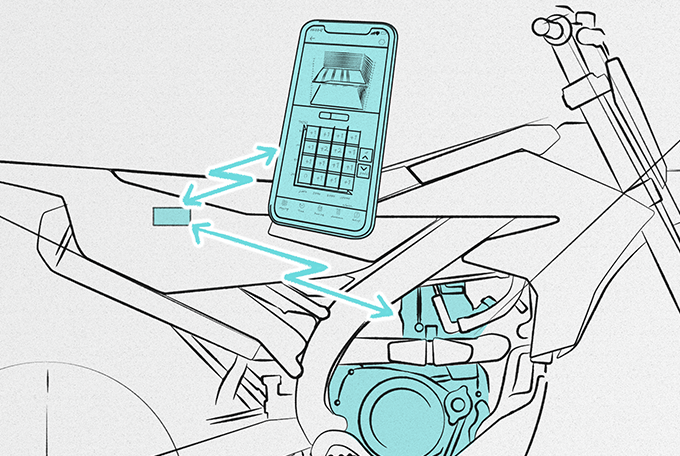

The word “DiASil” is an abbreviation of “Die-casting Aluminum-Silicon.” With our pizza example, the amount of heat in the oven is the die-casting technology, the baking pizza is the aluminum, and the onion and pepperoni are the silicon. If the pizza contains just the right amount of air in it, the resulting texture makes it delicious, but it’s the opposite with a DiASil Cylinder. The die-casting mold is kept free of air as much as possible. This is where Yamaha casting experience comes in.

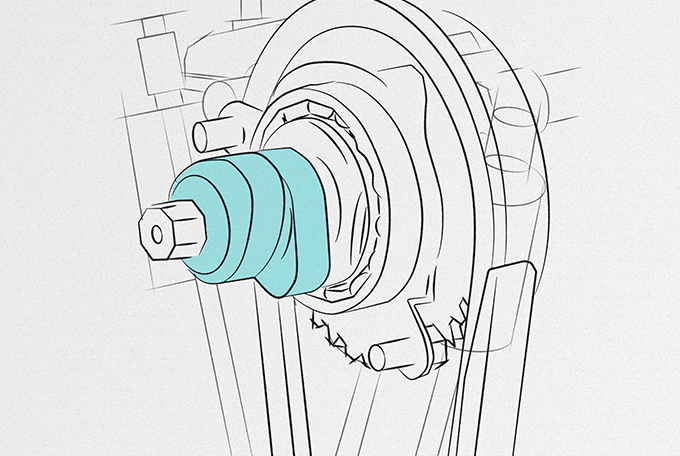

If a steel sleeve is used, it must be machined with angled grooves on the surface to hold oil. But in a DiASil Cylinder, the tiny particles of silicon on the surface serve this same purpose, so the oil flows along the flat surfaces between the silicon particles to provide good lubrication.