Comparison

Comparison of water purification methods

Comparing the slow sand filtration method we are adopting with other typical water purification methods in the world, it is shown in the table below. Boreholes are not a water purification system, but they are used in many areas in rural areas of developing countries, so we compared them together. We assume that the required area and initial investment will be the same amount of purified water production.

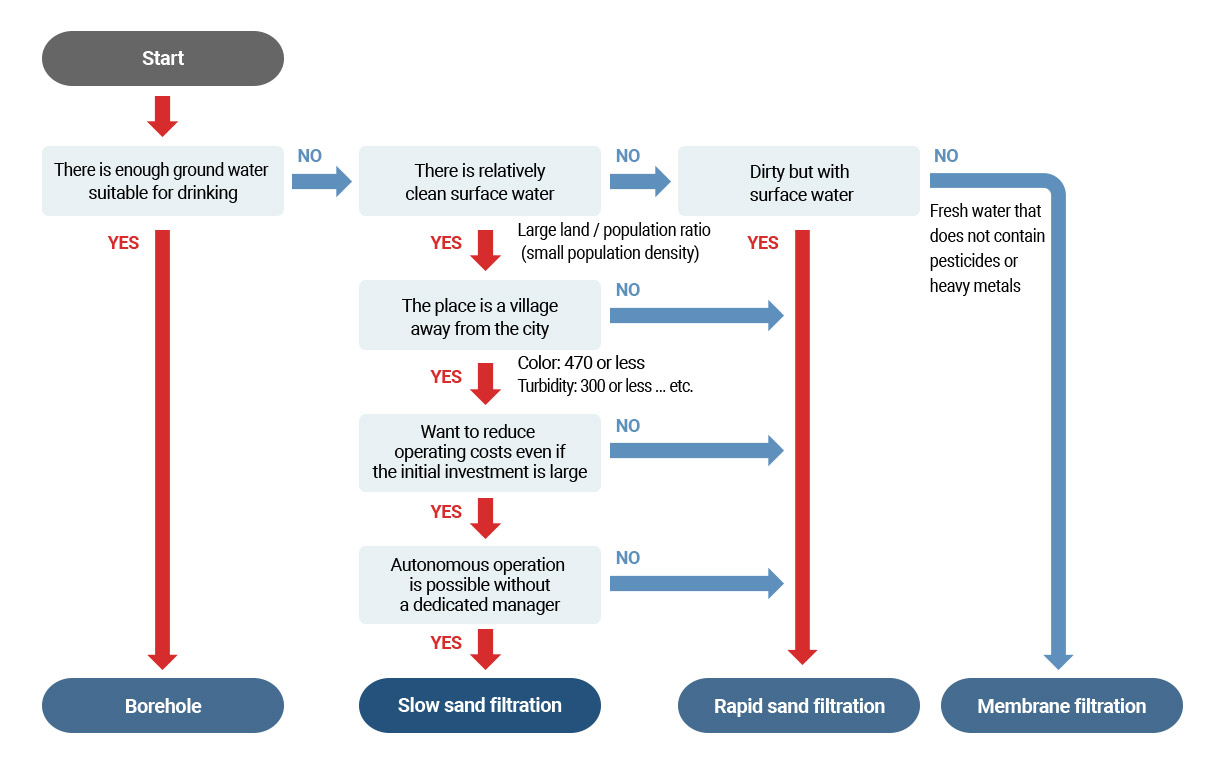

Slow sand filtration is ideal for small villages with relatively clean surface waters, enough land, and firm self-governance. On the other hand, rapid filtration is more suitable in areas with high turbidity of raw water and urban areas with a large population and difficulty in securing land. Also, if you don't have fresh water or if you have arsenic contamination, you have to resort to membrane filtration. Even in small villages, if you have enough clean groundwater that is good to drink, you can also have the option of a borehole.

Comparative overview of water purification methods

| Item/water purification method | Borehole | Slow sand filtration | Rapid Filtration | Membrane filtration |

|---|---|---|---|---|

| Appropriate areas | A place with enough clean groundwater suitable for drinking | Small villages with relatively clean surface waters, enough land, and firm self-governance | Populous urban areas Areas with high levels of raw water turbidity |

Anywhere, including places with little fresh water and arsenic contamination Public funds cannot cover running costs |

| Purification performance | ★ Have no purification capacity |

★★ Can purify relatively clean water without fine particles |

★★★ Relatively fine particles can be collected and sedimented |

★★★★ Able to remove ultra-fine particles such as desalination of saltwater and removal of heavy metals |

| Required area | ★★★ Small |

★ Large |

★★ Relatively small |

★★★ Small |

| Initial investment | ★★ Relatively small |

★ Large |

★★★ Small |

★★★ Small |

| Maintainability | ★★★ Available to local users |

★★★ Available to local users |

★★ Specialist and technician needed |

★★ Specialist and technician needed |

| Environmental adaptability | ★★★ There is no emissions |

★★ Waste is raw water |

★ Waste is sludge containing coagulants |

★★ Waste is raw water |

| Running cost | ★★★ Cheap |

★★★ Cheap |

★ High (coagulant) |

★ High (e.g. membrane exchange, electricity) |

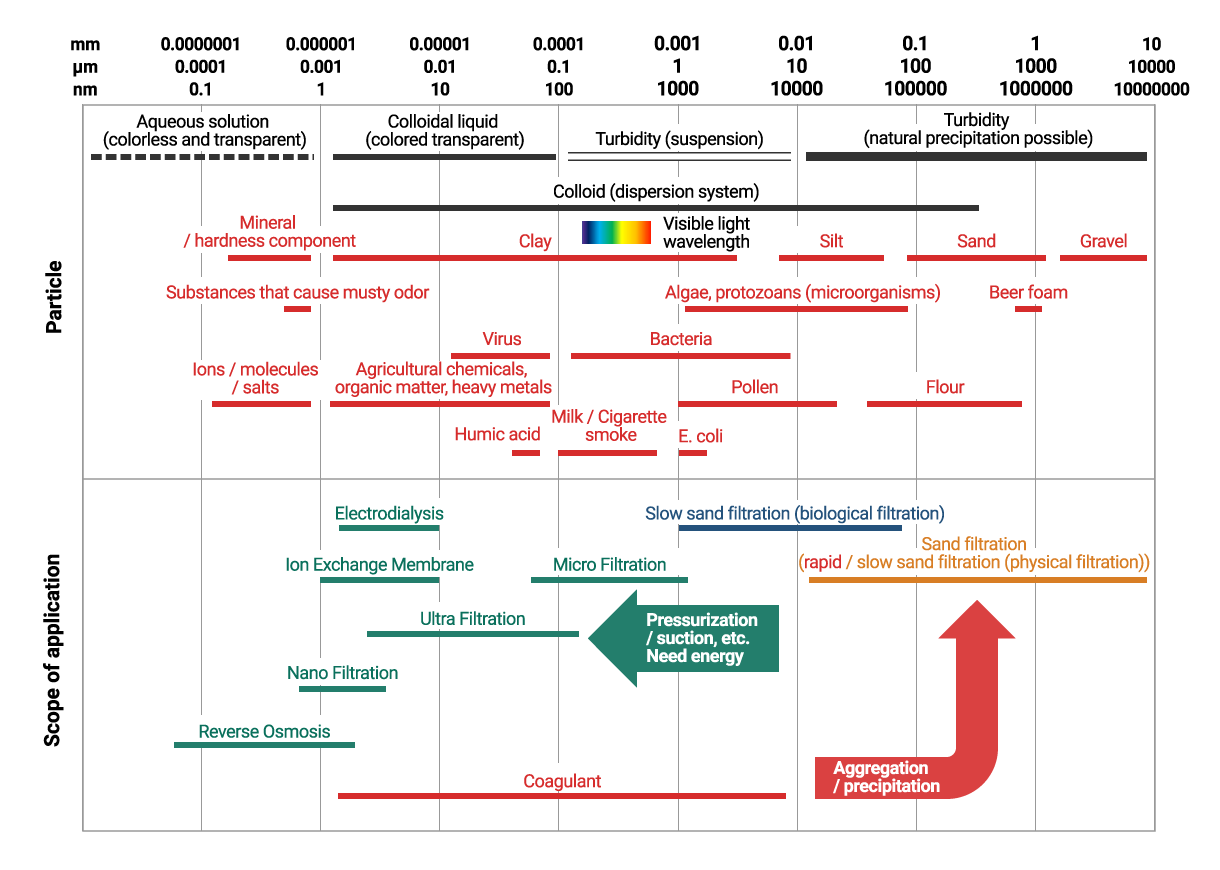

Particle diameter of impurities and application range of each water purification method

The following diagram shows the particle diameter of impurities and the application range of each water purification method. Each method is rarely used alone, and in most cases, multiple methods are combined for preprocessing and postprocessing. YCW also combines coarse filtration (using gravel instead of sand but a type of sand filtration), sand filtration, and biological filtration.

Which water purification method is most suitable for you

What is the slow sand filtration?

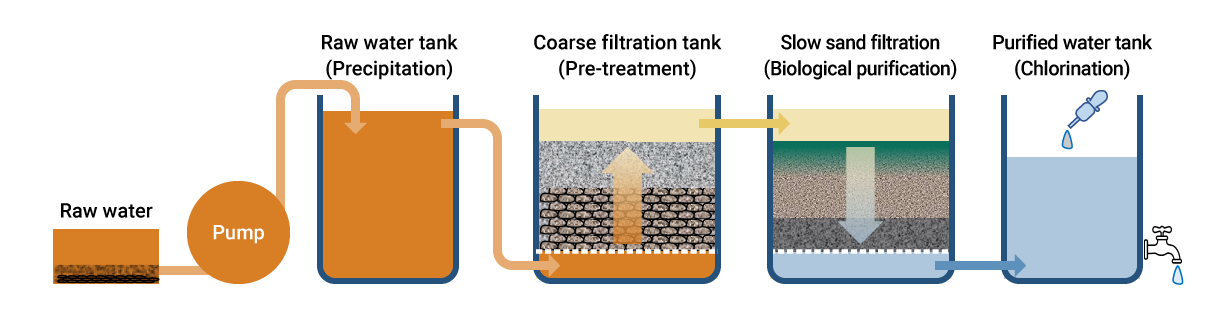

Developed in the United Kingdom in the late 1820s, the sand filtration method spread from Europe to the world. Usually used for the treatment of surface water, the flow rate is 2 to 5 m/day, which is slower than the rapid filtration method described later. In Japan, the rapid filtration method that came in from the United States after World War II became widespread, and the slow sand filtration method that had been used up to that time drastically decreased. In recent years, however, there have been moves to be reconsidered even in Japan due to the small environmental impact and energy consumption.

In the slow sand filtration method, water is purified not only by physical filtration but also by the formation of a microbial membrane layer through sand filtration. The layer of this microbe is called biological filtration membrane, and it forms in the upper layer of the sand layer, a few to several tens of millimeters, about two weeks after the commencement of operation. Biological filtration membrane is formed by microbes such as bacteria, fungi, and protozoans. Over time, algae increase and larger aquatic organisms begin to inhabit. When water passes through the biological filtration membrane, foreign matter is caught in viscous membranes, and dissolving organic matter is absorbed and used for the metamorphosis of bacteria, fungi, and primitive animals.

Features of the slow sand filtration

- It is necessary to keep the low flow speed without interruption because of the biological treatment.

- Due to the slow speed of water purification production, water is usually often stored in a storage tank.

- In addition, for the production of the same amount of purified water, a large area of installation is required compared with the rapid filtration method.

- Equipment can be simplified without the need for additional equipment such as chemical treatment.

- Use bioremediation capacity for water purification.

- Purification itself does not require pressurization, chemicals or electricity.

- Suitable for purification of raw water with low turbidity.

- Under conditions of high turbidity of raw water, pretreatment such as coarse filtration may be necessary.

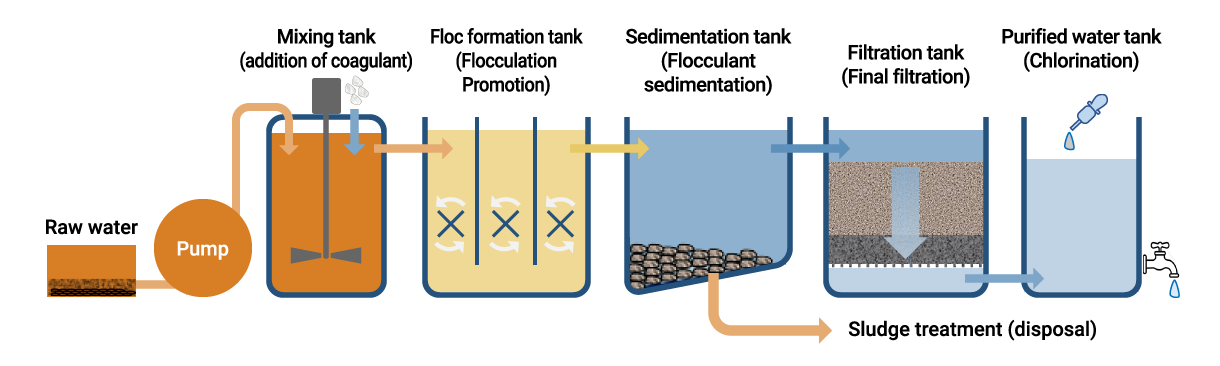

What is rapid filtration?

Developed in the United States in the late 1890s, this sand filtration method came into widespread use in urban areas around the world. Compared to the slow sand filtration, the flow speed is 120 to 150m/day, which is several tenfold faster than the slow sand filtration mentioned above. Because the land area required to produce the same purified water is small, it is widely used in urban water purification plants, where the population density is high and land is relatively hard to obtain.

The rapid filtration method is a method to filter impurities in the water by using coarser sand and gravel compared with the slow sand filtration. Prior to filtration treatment, coagulants such as aluminum sulfate and polyaluminum chloride are added to coagulate fine particles and increase the amount of impurity particles, thereby facilitating filtration. Also, after filtration treatment, it is disinfected with chlorine or ozone.

Features of rapid filtration

- Compared to the slow sand filtration, the flow speed is larger, so the installation area can be relatively small.

- It is also possible to deal with water with high turbidity.

- The amount of sand required as a filtration material is relatively small.

- Control techniques and costs such as coagulant addition and backwashing are required.

- There is a continuing need for the cost of buying coagulants.

- It is difficult to get rid of bacteria alone.

- The coagulated sediment, sludge, needs to be treated.

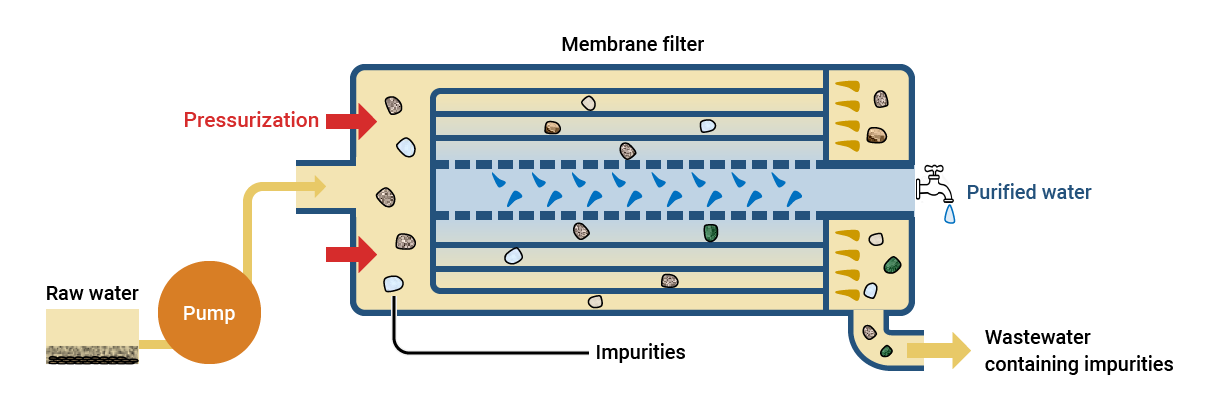

What is membrane filtration?

This is a process in which raw water is passed through an organic or inorganic porous filter to remove impurities by the principle of sieving. They purify water by leaving impurities larger than the pores of the filter in the filter and allowing only smaller substances, i.e. clean water, to pass through.

Depending on the size of the pores through which the substances pass, there are four types of membranes, in order from coarser, the microfiltration membrane, the ultrafiltration membrane, the nanofiltration membrane, and the reverse osmosis membrane. The micro filtration film has a pore size of about 0.1 to 1μm, allowing the system to remove algae, worms, and bacteria. With an ultrafiltration film, the size of the pores can be around 2 nm to 0.1μm, allowing for the removal of even the protein levels of viruses and macromolecules. Reverse osmosis membranes have the smallest pores and are able to remove nearly all the components that dissolve in water. Because even small molecules such as salt (sodium chloride) can be blocked, they are also used in devices that desalinate seawater. Nanofiltration membranes have pore sizes of 2 nm or less, which are intermediate between ultrafiltration and reverse osmosis membranes.

Features of membrane filtration

- If the removable impurity size is clear and a suitable membrane is selected, impurities of a certain or larger size such as suspended matter, colloids, bacteria, cryptosporidium, and the like in raw water can be completely removed.

- Microporous membranes, such as reverse osmosis membranes, can completely remove mineral components and substances responsible for musty odor without combining multiple treatments.

- Pretreatment is reduced, the facility composition is concise and compact, and the site area can be narrowed.

- In raw water with high turbidity, the membrane is immediately clogged, so pretreatment is required.

- The construction period of the equipment is also short, and automatic operation is easy.

- It is necessary to apply high pressure, and energy consumption is large.

- There is a possibility that the maintenance cost of the membrane and the system will be higher.

- In the reverse osmotic membrane, the cost of the membrane itself is also high, and the energy consumption for obtaining high pressure is also large.