A New Era of Yamaha Handling: The YZF-R1 Fast and Lightweight, but Handling Was Its Forte

(Return to Part 1)

There was still one type of bike that Yamaha hadn’t added to its lineup: an “ultra-hypersport” model like the ones its competitors had with a 4-stroke, 4-cylinder engine. Yamaha’s established line of 4-stroke, 4-cylinder models—including the YZF1000R Thunderace and FZR1000—had been developed from the start with product concepts that were different from the offerings of Yamaha’s rivals. Even though they were designed to be high-performance bikes, Yamaha believed that big-bike users would actually be using their motorcycles for touring. In order to enjoy that kind of long-distance riding, qualities like very quick handling, for example, would force the users to ride with a higher level of tension, and Yamaha refused to do this with its motorcycles. This uniquely Yamaha philosophy was the main reason the company had never developed an extremely light and compact liter-class model like the CBR900RR.

The only exception was the FZR750R (OW01) which was designed specifically for World Superbike homologation. The Yamaha philosophy regarding supersport models had always been to develop the machine with a focus on its touring capabilities, and then supplement it with sporty performance. But now, Yamaha did the exact opposite in designing an ultra-hypersport model in the YZF-R1. What had happened? Had Yamaha changed its way of thinking? The answer to that question became apparent the first time we test-rode the R1. Yamaha’s developers had succeeded in solving the problem that had caused them to dislike the ultra-hypersport bike category until then. Looking only at the R1’s specs like the engine’s exceptionally high power output and quick response, and the extremely light and compact chassis, one might suspect that Yamaha had focused solely on outdoing the competition on the spec sheet. However, Yamaha’s aim had been on a completely different level: the R1’s handling.

YZF-R1 (Released in 1998)

Launched in 1998, the YZF-R1 is the first model of the R-Series and would define the next generation of supersport models. At the start of its development, the displacement of its engine was undecided and would only be set later through the results of tests to determine the ideal torque values for sporty riding on twisty roads. The model featured a new engine with a compact, three-axis layout, a long swingarm based on GP machine theory and more.

Even with aggressive riding, the R1 always felt natural and in tune with the rider’s perceptions. It was easy to control every aspect of its performance. What set the R1 apart from its rivals most was this handling. I recall the reaction of one of the members of the RIDERS CLUB editorial staff, Toshinobu Taketazu, at the R1’s European press release and test-ride event. Excited after his test-ride, he kept saying how easy the bike had been to ride, despite its awesome performance. I, too, became completely absorbed in my test-ride of the R1. As I repeated the process of entering a corner, going through it and feeling the traction [exiting the turn], I found that the more serious and aggressive I got, the more fun the bike became to ride. When this kind of thing happens, things like spec numbers are already irrelevant. It was purely an experience of savoring the ride. It was the same kind of revelation I had when I rode the first-generation 2-stroke TZR250. It seemed a forgone conclusion that Yamaha’s first 4-stroke, 4-cylinder ultra-hypersport bike that was focused completely on sporty riding would be different from anything else, and this thrilled me no end.

I told the Yamaha developers how moved I had been by their creation, and talked with them about the development process. I was left even further impressed, because I realized that they had all devoted themselves to making this bike as riders themselves rather than as “engineers.” In order to elicit the feelings and perceptions they wanted as riders, they worked meticulously, not simply based on “feeling” alone but on creating technologies that were concrete and specific. It was work that they had truly put all their heart and soul into. For example, instead of saying that the Yamaha team had aimed to build a bike with high-level engineering by doing things like designing the layout of the engine to fit the handling demands for the chassis, it’s more fitting to say that they worked to create the ultimate item to experience and enjoy riding to the fullest. That’s what would be expected from a company known for the “Yamaha Handling” of its motorcycles. What’s more, I was impressed by the fact that most of the members of the development team were in their thirties. Through the development of the R1, they had succeeded in translating Yamaha’s traditions into genuine knowhow and technologies, and in the process, opened up a new era of Yamaha Handling.

Frame Flexibility in True Yamaha Style No Compromises in Creating a New Era of Handling

From the moment you begin to lean the bike into a turn until the moment the tremendous amount of traction you apply to the road surface picks the bike up as you accelerate out of the turn, “exhilaration” is the only word that can truly communicate the feeling of the R1’s cornering performance. But, what impressed me most of all was when switching lean directions while going through an S-curve. Weighing just 177 kg, the bike’s agility was just as I imagined it would be, but it was the quality of the movement that exceeded my expectations. Picking up the machine from a lean was not only light but also very natural in feeling, and then leaning the bike in the opposite direction was quick, smooth and without resistance. While the load on the tires decreases and increases rapidly [during braking and acceleration], the feeling of contact with the road remains the same for both the front and rear.

Even if you do a very quick changeover, there’s no indication of sudden changes in the way the steering feels. I have never known a big hypersport bike on which you could flick it through S-turns as cleanly as with the R1. In the action of switching from right to left and left to right, there are a number of complex and active factors at play, from the alignment of the un-sprung components to the suspension dynamics. I could go into great detail in analyzing the numerous advantages of the R1 that I experienced, like how well its suspension works. But here, I will limit my focus to the one area that made the biggest difference in the fantastic feeling the ride offers. That is none other than the rigidity of the chassis.

I asked Yamaha development test rider Yoshitaka Kojima about this. “It’s by no means a highly rigid chassis. We had actually tried to create a rather low level of rigidity,” he said. The super-compact engine is mounted to the aluminum Deltabox frame by means of rigid mounts—with two at the rear end of the crankcase and one on the upper half of the crankcase that is cast as a single unit with the cylinder block—and functions as a stressed member of the frame. Because the engine has a short overall length, it’s especially rigid as a stressed member of the frame, making it possible to lower the rigidity of the frame from the pivot assembly to the back of the steering head-pipe compared to the levels usually required for a machine of this class.

Generally speaking, if the frame is too rigid, that’s good for straight-line stability, but cornering performance and handling typically become heavier. No matter how light the machine may be, this excessive rigidity can make a 200 kg bike feel like a 250 kg bike to the person riding it. Of course, it’s no good if there’s not enough rigidity either, because that will result in a shaky feeling and a loss of handling performance. You want to give the bike the right amount of flexibility, but the common practice is to design the rigidity with a somewhat limited amount of flexibility to maintain a good margin of rigidity. However, the R1 development team made no compromises. “There are very few chances to design and build not only the engine but the entire bike from scratch with all-new components. We felt that this bike’s meaning would be lost if we didn’t achieve concrete and substantial advances in all areas of the bike and its performance,” Kojima concludes.

Emphasizing the Response When Closing the Throttle Agile Performance through Both the Chassis and Engine

While the chassis was still in the development stage, the development team would adjust the rigidity by applying patches one after another. Kojima says conversations like, “We’ll take it back now and remove the engine, do the welding tomorrow and have it back here for track testing the day after tomorrow” became commonplace. The result of those efforts was a difference that you could clearly feel when you rode the R1. It wouldn’t be an exaggeration to say that it felt even lighter than a 400cc class model. But this lightness was only partially due to the excellence of the chassis. When starting a lean or when bringing the bike back upright, it only took the slightest input from the rider to get a virtually instantaneous response from the chassis. Immediately after that came a quick subsequent response from the front assembly. Of course, it wasn’t a sharp response that would take you by surprise. Rather, it was a quick feeling of dynamic response from the front following the rear with no change in the feeling of contact with the road. For example, with sporting equipment, if it’s too stiff, it feels heavy, so if you give it the right amount of flexibility, it feels lighter in use. The result is that you can hit a ball farther, or in the case of board sports, you can make sharper moves.

YZF-R1 (Released in 1998)

With the R1, there’s this kind of “sporting equipment flexibility” between the steering head and the engine mounts. Especially in situations like S-curves where you bring the bike up from one lean and want to lean it over immediately in the opposite direction, the quick response you get going into the lean really feels very good. I was completely taken by this new, and truly sporty feeling I found in the R1.

The best thing about this flexibility is probably that it feels lighter and quicker the faster you try to steer the chassis, and when you steer it more slowly, you can take larger turns with an assuring feeling of stability and no sudden changes in the steering characteristics. Naturally, there are many other factors that contribute to the bike’s excellent dynamics such as the quality performance of the suspensions, but there is one more important element that makes the R1’s chassis flexibility such a positive factor: the steering head.

The R1 not only has a large-diameter steering head but also adopts a large-diameter spec for the steering head bearings that help hold the front fork to increase rigidity. Both the lower bearings—which receive most of the load forces—and the upper bearings have this large-diameter spec. What’s more, the bearing seals also have a compact structure with low rotational resistance. The front fork’s aluminum steering shaft is a tapered type like those used on race machines. The aim is of course to improve steering response; it provides a steering character that responds quickly and smoothly to even the slightest lean of the chassis. This functions to more effectively convey the feeling of the chassis’ flexibility.

The next thing I want to mention in connection with the R1’s performance when riding through an S-curve is engine response. “Everyone wants to improve the engine’s response when you open the throttle, and that always makes the bike better. But, we focused on the response when you close the throttle,” says Kojima. They wanted to achieve performance that was solid not only during the rhythmical banking of the chassis from left to right as you fly through the corners but also enabled the rider to work the throttle to get momentary spurts of traction on and off through the turns. If you can immediately add or remove traction to the road as desired in this way, you can enjoy riding through consecutive turns even faster. The R1 is a bike that you can do this properly and with certainty.

“When you closed the throttle quickly, we wanted a response that would only slightly change the machine’s attitude on the order of a few millimeters when approaching the inside of a turn. Next, when you quickly opened the throttle up again, we wanted it to instantly load the rear,” explains Kojima. And, true to those words, the R1 responds to that kind of throttle work and zooms through turns and curves one after another, just as the rider intends. The minimized attitude variance provided by the R1’s extra-long swingarm and the good initial compression characteristics of the front fork and rear suspension also greatly contribute to this, but more than anything, it’s the way closing the throttle cuts off the drive force almost instantaneously that makes this kind of cornering performance possible. If the drive forces disappear more gradually after closing the throttle, it causes a slight time lag in the shifting of load forces and results in unnecessary pitching of the suspension that can bring undesired momentum when loading the front end. The R1, however, does this in the blink of an eye and results in little change in machine attitude and less fluctuation when loading the front end.

For me, it was truly surprising to see how getting the right combination with the engine’s power delivery, frame and suspensions could have so great an impact on a motorcycle’s performance that even the feeling of lightness was on another level. Furthermore, the engine response when opening the throttle is also quick, but it doesn’t produce sudden bursts of power, making it very easy to open up the throttle. The engine, with its new 20-valve design (five valves per cylinder), adopts steeper valve angles and smaller-diameter valves to ensure strong power output from the low-rpm range. At the same time, a straighter layout for the intake system was designed to accommodate this, and thorough measures were taken to reduce loss throughout the engine’s various parts, boosting its maximum power output to 150 PS. Since this high level of performance has been achieved by smoothing out the engine mechanically, response is also very sharp. When you rev the engine in neutral, you are delightfully surprised at how quickly the tachometer needle shoots up to the high-rpm range. With this kind of revving performance, you would expect the response to be hard to handle in a 2nd-gear turn. However, the R1 has two separate response settings for 1st to 3rd gear and then for 4th to 6th gear.

By the way, regarding engine management, the ignition timing control system and Yamaha’s exclusive Exhaust Ultimate Power Valve (EXUP), which corrects for blowback in the exhaust system, are controlled by means of mapping based on the five parameters of engine rpm, vehicle speed, degree and speed of throttle opening and gear position. This control system not only enables a wider range of strong, easy-to-use power but is also tuned in a way that doesn’t bring excessive response that might cause dangerously sharp changes in machine attitude when opening the throttle when exiting turns in 1st, 2nd or 3rd gear where the gear ratios are low.

“During development, when I’d wake up in the morning to find it raining, I wasn’t disappointed but actually excited, because a wet track gave us an opportunity to see just how much solid progress we’d made,” says Kojima. A statement like this was strong evidence of the passion the team brought to their development work.

But, this is just the beginning of their story. Now we turn to the specifics of the layout of the R1 chassis and the focus of each component’s design and functions.

Greater Cornering Ease via Engine Positioning A Swingarm Making up 42% of the Wheelbase

The digital speedometer reached 291 km/h as the machine’s top speed. It didn’t seem like the bike could reach the 300 km/h mark that everybody in the industry had been talking about at the time, but in typical Yamaha style, the R1’s developers showed little interest in such numbers. Nonetheless, the speed with which the R1 reached 290 km/h was certainly fast. Speeds up to 270 km/h felt like the R1’s “mid-range” for acceleration, and it would continue to accelerate with the same performance it had in the lower gears. Peak power was produced at 10,000 rpm, but it could be easily over-revved above 11,000 rpm. This was further evidence that the speed at which the engine revved was on a completely different level from the 20-valve engines used up through to the Thunderace era. However, I got carried away during my test-ride and made a big mistake on a high-speed corner of the test course. There’s a dip on the track on the outside of the turn that takes the load off the tires, but because of the machine’s good feeling of stability, I got careless for a moment and raced through the curve at full throttle in 4th gear. Then, from the sound of the engine revving as if it was in neutral, I realized that the rear wheel had started to slip, and at that moment the rear started to slide sharply out to the side. I reacted instinctively by cutting back the throttle to reduce the drive force. I thought my heart was going to stop, but the R1 settled back to normal much more smoothly than I would have ever expected.

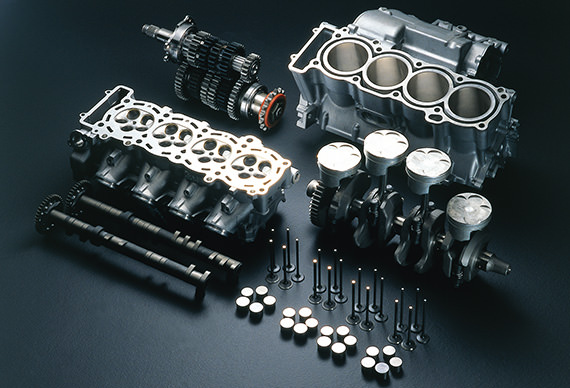

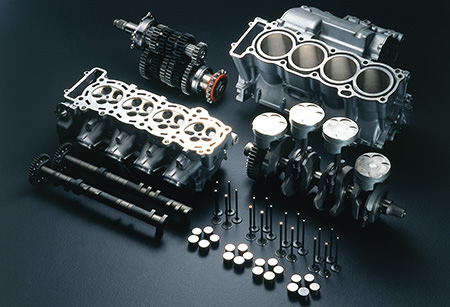

The YZF-R1’s liquid-cooled DOHC 5-valve engine

(1998 year model)

The R1’s engine was the result of dedicated efforts to improve intake and exhaust efficiency, and its valve train adopted 3 intake valves and 2 exhaust valves for each cylinder. In order to make it a more compact and mass-centralized power unit, the crankshaft, the mainshaft and the driveshaft were positioned in a triangular, 3-axis layout.

The R1’s wheelbase was set at a short 1,395 mm with the aim of increasing cornering ease. When you’re faced with the rear breaking out like this, it would be natural to expect the rear to slide powerfully to the side, after which—if you managed to escape a fall—the machine would still subject you to a series of short, strong jerks with enough force to throw you off before it settles down. With the R1, however, the rear began to swing out comparatively slowly and there was a composed manner to the way it settled back to normal motion. This was due to the merits of the extremely long swingarm that functioned to minimize changes in machine attitude like up and down pitching motions despite the short wheelbase.

This long swingarm is an important factor in the R1’s excellent handling. When going over a rough section of track, for example, its length moved the center of the pitching motion closer to the center of the machine, thus reducing the degree of movement. It’s well-known that the moment when you lean the machine over to enter a corner and the bike banks over with no pitching motion is when taking the line that you want through the turn becomes easier.

Naturally, these characteristics of minimal attitude change in decisive moments like this contribute greatly to making the R1 easy to ride. But, the biggest merit of all is its stability when powerful traction against the road kicks in as you quickly open up the throttle to pick up the bike as you exit a curve. First of all, because the road contact point shifts less during suspension movement compared to a shorter swingarm, you can reduce the likelihood of slippage, etc., (when the engine revs as if it’s in neutral) when strong drive force is applied. In the same sense, it’s easier to set the bike’s alignment in a range that prevents the front from coming up, etc., when drive force from the rear wheel pushes the chassis in the direction of forward motion. With a shorter swingarm, the direction (vector) the chassis is being pushed in differs depending on cornering speed—whether the suspension is greatly compressed or not—making it easier for things like wheelies to occur. This makes it more difficult to steer and accelerate out of corners with confidence. The R1 had an excellent feeling of stability when accelerating out of corners that allowed anyone to enjoy getting powerful traction from the road.

The swingarm on the R1 is 582 mm long. That's equal to an amazing 42% of its wheelbase. What made this length possible was the new 20-valve engine. As you can see, this engine is incredibly compact. For its length in particular, a very short layout is achieved by positioning the drive sprocket directly behind the crankshaft. When looking at it from the side, you can tell that the engine has a unique structure with the clutch positioned higher than usual. This is because the three axes (clutch axis and two transmission axes) are positioned in a triangular layout like a GP race machine instead of the conventional horizontal alignment from the clutch axis to the two transmission axes. That’s not all though. The oil pump and water pump are built into the lower portion of the crankcase to make the design even more compact. With a GP machine, the engine is positioned as far forward as possible without interfering with the front wheel in order to inhibit front-end lift as much as possible. However, on the R1 the engine is deliberately mounted in a position slightly behind that limit of front wheel interference.

The reason behind this positioning is the development priority on steering response that allows for easy cornering, even with a light lean from an attitude a bit more upright than fully banked over. This is another choice of priorities that reflects a truly Yamaha spirit

The YZF-R1’s aluminum Deltabox frame and chassis (1998 year model)

After ensuring the frame had outstanding longitudinal rigidity, the team worked to find the optimum rigidity balance for its latitudinal and torsional rigidity. The bike also adopted a long swingarm that made up 42% of the model’s short wheelbase.

Priority on Functions: Not Everything Can Be Made Lighter Suspensions Also an Undeniably Major Focus

It required a great amount of development effort to get the R1’s weight down to 177 kg. “I used to joke and say, ‘Before we manage to get the bike any lighter, we’re going to end up losing weight and collapsing from working so much!’” recalls Kojima. Even though they had succeeded in making the engine very compact, accommodating the high power output meant that parts like the shafts and clutch had to be made stronger, and thus they became heavier. Also, because the crankcase would be used as a stressed member of the frame, sufficient strength had also been a prerequisite in its design. One might assume that since the direction for the chassis development was one of reduced rigidity, the team wouldn’t have to worry about greater weight for the chassis components, but in fact, things weren’t that simple. One example of the difficulties was in the upside-down front fork.

With the suspensions, the amount of suspension travel that remains after the initial sag produced by a rider sitting on the machine is called the suspension’s stroke. This functions to prevent the road contact pressure of the tires from immediately decreasing such as when going over bumps in the road or when there is a sudden decrease in load force. In conventional machines of this class, the stroke of the front fork is usually 110–120 mm and the rebound stroke is set at 35–45 mm. On the R1, these settings are both longer, with a full stroke of 135 mm and the rebound stroke set at 55 mm. “When you ride in Europe, there are a lot of rougher road surfaces. Under full acceleration, it’s easy to lose a feeling of contact with the road with the front wheel because of the resulting front-end lift. But I knew that a bike that you can’t open up the throttle with would be meaningless, so I strongly suggested that we lengthen the rebound stroke,” Kojima says. The chassis engineers’ hearts sank—increasing the stroke would inevitably make the fork heavier.

But, when a prototype with a new longer stroke spec was actually tested, everyone confirmed that it made the machine easier to ride. I’m told that the engineers that day gave in and said they would try to somehow achieve the longer stroke, and left the test course with a new weight on their shoulders. Thanks to their efforts, however, the R1 achieved a ride that maintained a stable feeling of road contact even when forces tried to lift the front in the very-high-speed range. Of course, even when accelerating out of a curve, the front wheel would only tend to lift easily from a burst of acceleration in low gear, and you could still accelerate with confidence [past mid-corner] without losing the feeling of road grip.

Another outstanding characteristic was the front fork’s initial compression characteristics. It reacted well to even the slightest shocks, and at moments when load is suddenly reduced, it functioned without resistance quickly and smoothly. When initial fork compression is poor, the rebound becomes that much longer, which in turn spoils the handling. If the suspension doesn’t follow the road surface well enough, there will be an instant when the tire’s tread loses road hold when the front tire’s contact surface changes from right to left, like in an S-curve. The weight of the front wheel, which is normally on the road, suddenly becomes supported solely by the front fork, making the handling feel unexpectedly heavy.

Furthermore, when the tire’s grip surface shifts from right to left or vice versa, it’s easier for “kickback” (a feeling akin to the road surface “hitting” the machine) to occur. But, even when you turn quite sharply with the R1, its front wheel sticks to the road and continues to follow the road surface smoothly, so the cornering feels smooth and the steering response feels natural. If the suspension’s rebound is slow and can’t follow the road quickly enough, there’s the danger that the bike will feel very sluggish, but you don’t find that symptom with the R1 either. While the development priority was on achieving the desired rebound potential, the bike adopted 41 mm diameter inner tubes in order to improve initial compression and reduce the risk of the handling feeling sluggish as much as possible.

“Some people said, ‘why aren’t we using a 43 mm spec fork in this day and age?’ Instead, we took our time in developing the front suspension until we got it right,” Kojima explains. From the rear suspension link settings down to the most detailed of specs, the team spared no time or effort, and tested and verified the many changes they did by actually riding the bike. It was this long and dedicated development process of trial and error that finally produced the great balance the R1 always maintains in a variety riding situations.

A fun ride is the result of true dedication but a bike that’s “easy-to-ride” still requires the basics

“Since we already had experience developing a big-twin model, we really wanted to develop this model with the unique appeal of a 4-cylinder engine. So, we also focused on setting a riding position that would make the most out of the traction from the road that a 4-cylinder engine could deliver. We wanted to give the footpegs a position that allowed riders to hold on as if they were kicking the bike away from the direction the rear tire’s point of contact with the road was traveling,” explains Kojima. The team had also designed the shape of the fuel tank with a focus on greater freedom of riding position. “With the first clay model, people noted that the original long fuel tank design would make the bike hard to ride if it moved in a certain way, so we sawed it off by 50 mm on the spot. That did leave us wondering how we were going to get the 18-liter capacity we needed. The knee-grip area actually has a slight bulge. This enables a natural grip without even thinking about it. The grip points of the thighs and ankles are another place where we can’t allow any compromising. So, the footpegs and their brackets were carefully designed to have the same feeling as the other grip points,” notes Kojima.

Seat grip was another area of important focus, from the shape to the firmness of the urethane cushioning material. For those of you that are into riding through the twisties, the developers were full of stories that would make you want to take the R1 out for a ride right away. A bike like this developed with so many qualities aimed specifically at making the ride fun and exciting couldn’t help but capture a rider’s imagination. “I spoke earlier about how we focused on the throttle response when both opening and closing it. One of the members of the team came to be known as the ‘professor of throttle [operational] load.’ In the course of working on the settings for throttle opening and operational load, he began using a spring balancer to collect data about the dynamic friction between the wire and the throttle holder. He began to wonder what it was like on factory racing machines," remembers Kojima.

“With the chassis and the suspension, things usually boil down to how they feel, but if you can’t find a way to translate that into a rationally based mechanism backed by data, you can’t fully develop it into something really interesting. However, that kind of work isn’t explicitly assigned to us, so if developers don’t take the initiative to pursue such research on their own, it won’t lead to any concrete results,” says Kojima. “But, in the end, it’s the greatest common divisor that determines the handling on a production model. Each rider has a different career, with experience on bikes of different types and from different eras, and some switch to a road-going bike from an off-road motorcycle. So, I believe that developing a bike that’s easy for everyone to ride is an accomplishment worthy of recognition. Still, I believe there will always be cases where a rider will feel this bike is just too difficult to ride. Especially, if you think that by just leaning a bike over it’ll turn, this bike will probably feel difficult to turn. If you don’t have the basics down, some riders may feel that when they try to turn, the front tends to shoot forward more than they expect,” he confides. As long a bike like this is developed with certain predetermined assumptions, such as where the merits lie for rider input, where you have to feel the bike’s motion and how you effectively control the throttle, etc., it is probably only natural that some riders will have some difficulty—especially since the R1 was designed and developed for the fun and excitement of riding an “ultra-hypersport bike.”

“My idea of sporty riding is not a matter of competing for lap times. A sport bike is something that the rider wants to control according to his or her own will and intentions. And if riders can do that at their own individual levels, they’ll have fun and work up a good sweat. But, if you go beyond your personal level and try to ride faster, you get a nervous sweat or a cold sweat—if not something worse. It’s not a simple game to play. But, I’m confident that the R1 is a bike that makes you want to put in another coin and give it another try,” Kojima concludes.

As for me, I’m sure my captivation with the R1 will last for quite some time.

(Continues in Vol. 10)

Yoshitaka Kojima, a member of Yamaha’s Road Testing Unit, 2nd Project Engineering Division at the time of the interview